SPECIFICATIONS

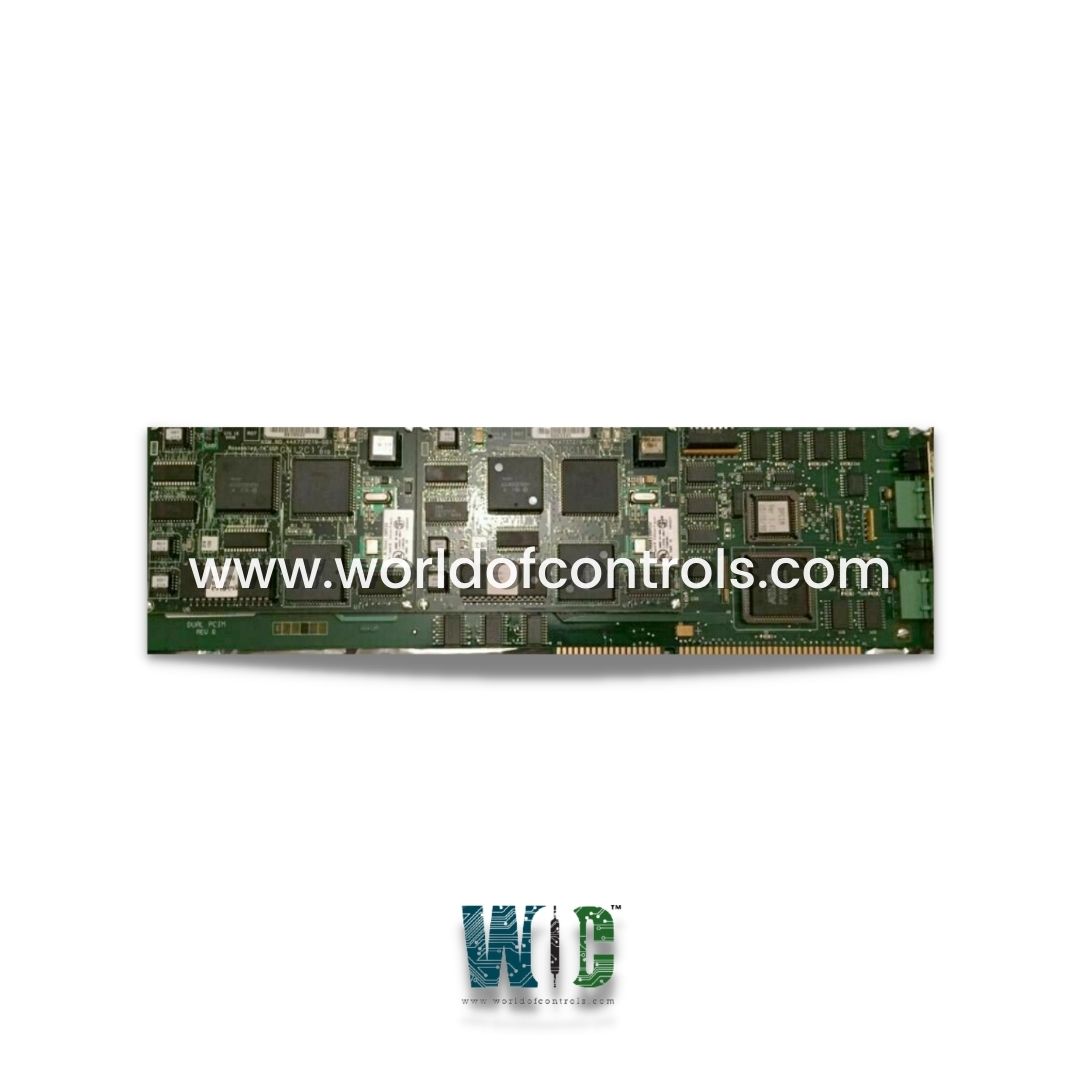

Part No.: IC660ELB922

Manufacturer: General Electric

Product Type: ISA Interface Card

Availability: In Stock

Series: VersaMax

Functional Description

IC660ELB922 is an ISA Interface Card developed for the Genius LAN interface by GE Fanuc. This card supports two independent LANs, each extending up to 7500 feet, and is fully compatible with handheld monitors (HHMs) as well as all GE Fanuc Genius bus controllers. It integrates seamlessly with Genius protocols at all levels, managing 8,000 inputs and 8,000 outputs.

Features and Form Factors

- The card is equipped to provide full-function bus controller capabilities for Genius I/O networks and is available in both PC-104 and VME form factors. It replaces the earlier two-slot card and includes two daughterboards, which offer a cost-effective tap into the Genius I/O bus. This configuration allows the host computer to control remote I/O with the high diagnostics, reliability, and noise protection of the Genius I/O System.

- The daughterboards can be independently configured using the included software, and the card connects to the Genius bus through board-edge connectors. The card is available in several product code variations: GEFIC660ELB922, CIMIC660ELB922, and ELB922.

- Depending on its configuration, can either read Genius block information (input-only mode) or write to Genius block outputs (output-only mode). Additionally, it serves as an entry point into the Genius I/O System for IBM PC/AT/XT series computers, tailored for integration into user-developed microprocessors.

Board Installation and Configuration

- For installation and configuration, the Genius PCIM card provides a comprehensive bus controller solution for Genius I/O networks, available in ISA, VME, and PC-104 form factors, with a PCI version in development.

- The newer models have succeeded the ELB906, with the ELB921 offering a more cost-effective option. Single-slot cards come with a DIP switch to define the I/O control port address, managing EEPROM data for GENI setup.

- Legacy software packages based on the ELB906 card might face issues with EEPROM configuration, making the TestGENI program a preferred tool for setup and diagnostics. This 16-bit DOS program, compatible with Windows 95 and 98, provides an interface for configuring EEPROM settings and troubleshooting hardware issues, though it is not supported by newer Windows versions.

Diagnostic Functions and Fault Reporting

The 115 VAC/125 VDC Isolated I/O blocks are designed with advanced diagnostic capabilities to ensure robust performance in industrial applications. These blocks feature built-in fault detection and automatic corrective actions that help maintain the integrity of the system by reporting faults and preventing potential damage to the I/O circuits. Below is an expanded explanation of the various diagnostics and fault reporting functions supported by these blocks.

Diagnostic Functions

Fault Reporting to Hand-held Monitor

The Isolated I/O blocks are equipped to perform a variety of diagnostic checks, reporting faults directly to the Hand-held Monitor. The Hand-held Monitor (HHM) continuously communicates with the block, allowing operators to quickly identify and resolve faults. The blocks also take appropriate corrective actions to ensure system stability. In cases where individual circuits are configured not to send diagnostic messages to the CPU, the blocks will still provide full diagnostics when the CPU requests information via Read Diagnostic Datagrams. This flexibility ensures the system can be tailored for specific needs, while still providing essential diagnostic details when required.

Loss of I/O Power Diagnostic

A unique diagnostic feature of the Isolated I/O blocks is the Loss of I/O Power Diagnostic. This diagnostic helps to detect when one pair of circuits is disconnected from the field power:

- Power Loss Impact: The block detects a loss of power and takes action based on whether the affected circuit is configured as an input or an output.

- Inputs: If an input circuit loses power, the block automatically sets it to 0.

- Outputs: If an output circuit is affected, the block turns it off.

- Automatic Fault Message: When this condition occurs, the block automatically sends a Loss of I/O Power diagnostic message to the Hand-held Monitor. However, this message is not sent to the CPU unless the block is Pulse Tested. This feature ensures that only relevant information is communicated to the CPU when necessary.

- LED Behavior: The Unit OK LED does not blink when there is a loss of I/O power, as the block is designed to handle this situation without unnecessary alerts. Once I/O power is restored, the circuits will resume normal operation as soon as the power reaches the minimum required level.

- Loss of Power to the Block: If the block itself loses power, it will not be able to send diagnostic messages to the CPU. In this case, the bus controller will treat the condition as a standard loss of block event, ensuring that appropriate actions are taken.

Overtemperature Diagnostic

Each I/O circuit within the block is equipped with a thermal sensor that monitors the block's internal temperature. The Overtemperature Diagnostic is triggered if the temperature exceeds 100°C:

- Protective Action: When the block's internal temperature reaches dangerous levels, it automatically sends an OVERTEMPERATURE message. To protect the block’s internal electronics, the affected circuit is turned off.

- Constant Monitoring: This diagnostic is consistently active, meaning that it is always performed for both input and output circuits. This built-in protection prevents overheating from causing damage to the block or the system it controls.

Short Circuit Diagnostic

The Isolated I/O block also incorporates a Short Circuit Diagnostic, which protects output circuits from damage caused by short circuits:

- Automatic Detection: Each output circuit is equipped with a short circuit level sensor. If an output circuit experiences a current surge above specified thresholds:

- Turn-On Current: If the instantaneous current exceeds 25 amps at turn-on.

- Subsequent Overcurrent: If the current remains above 15 amps for 2 cycles (AC) or 10ms for DC, the block will automatically turn off the output within several microseconds.

- Restoration Attempts: After the output is turned off, the block will attempt to restart the load. If the issue persists, and several restart attempts fail, the block will force the output off and send a SHORT CIRCUIT message.

- Fault Recovery: To restore normal operation, the cause of the short circuit must be eliminated. Once the fault condition is cleared, the diagnostic can be cleared from the HHM or CPU. This process ensures that faulty circuits do not continue to impact the system, and that operators can take corrective action before normal operations resume.

Configurability of Diagnostic Messaging

The Isolated I/O blocks allow flexibility in how diagnostic messages are handled. Specifically, individual circuits can be configured to not send diagnostic messages to the CPU when a fault occurs. This configurability is useful for minimizing unnecessary diagnostic traffic or for optimizing system performance in cases where the CPU may not need immediate notification of certain faults.

- Manual Diagnostic Requests: Despite the configuration of individual circuits, if the CPU requests diagnostic information from the block using Read Diagnostic Datagrams, the block will always return the current diagnostics for all circuits. This includes situations where the CPU fault reporting feature has been disabled, ensuring that operators can still retrieve relevant diagnostic information upon request.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IC660ELB922?

It is an ISA Interface Card developed by GE under VersaMax series.

How does the module connect to the Genius I/O System?

The board connects to the Genius I/O System using board-edge connectors. The card’s two daughterboards can be connected to the same or independent Genius buses, providing flexibility in network configuration.

What is the TestGENI program, and how is it used?

TestGENI is a 16-bit DOS program used for setting up and testing PCIM cards. It operates under Windows 95 and 98 but requires a DOS boot diskette for use with Windows NT/2000/XP. TestGENI allows users to configure EEPROM settings, check card status, and perform diagnostics.

What types of computers can use the module?

Designed for integration into IBM PC/AT/XT series computers and is suitable for use with user-developed microprocessors. It is also compatible with AT-type computers.

How do I configure the module?

Configuration involves setting the I/O control port address using a DIP switch and managing EEPROM data for GENI setup. The TestGENI program is recommended for setting up and testing the card, as it provides a user-friendly interface for configuring EEPROM settings and diagnosing hardware issues.