SPECIFICATIONS

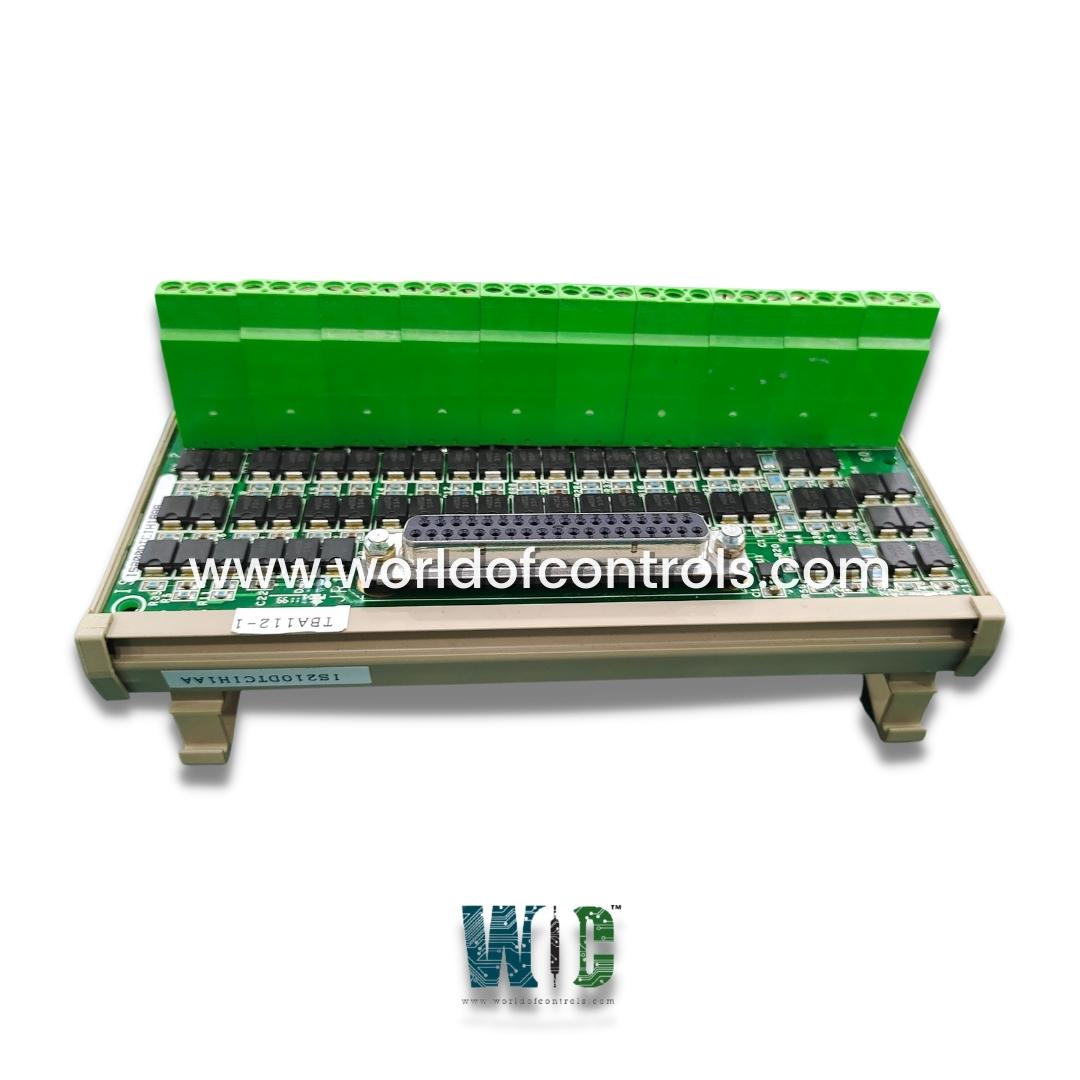

Part Number: IS210DTCIH1AA

Manufacturer: General Electric

Country of Manufacture: United States (USA)

Number of relay channels: 12

Size: 8.26 cm high x 4.19 cm wide x 12.1 cm deep

Technology: Surface-mount

Series: Mark VI

Function: contact input terminal board

Functional Description

IS210DTCIH1AA is a contact input terminal board developed by GE. It is part of the GE Speedtronic Mark VI gas turbine control system. The DTCI (Compact Contact Input) board is a versatile and efficient solution for contact input terminal needs, offering a range of features tailored to streamline installation and maximize functionality.

Features

- Compact Design: Engineered to optimize space utilization, the board boasts a compact form factor, ideal for installations where space is at a premium.

- DIN-Rail Mounting: Designed for DIN-rail mounting, facilitates hassle-free installation and integration into existing setups, ensuring compatibility with standard mounting systems.

- 24 Contact Inputs: With 24 contact inputs, provides ample capacity to accommodate a diverse range of input sources, catering to various application requirements.

- Nominal Excitation: 24V DC: Operating at a nominal excitation voltage of 24V DC, ensures compatibility with commonly available power sources, offering reliability and consistency in operation.

- Single Cable Connection to VCCC or VCRC Processor Board: Simplifying setup and reducing clutter, the board features a single cable connection to the VCCC or VCRC processor board, facilitating seamless integration into larger systems.

- Expandable to 48 Contact Inputs with Two Boards: Offering scalability, the board allows for the connection of two boards, effectively doubling the available contact inputs to 48, providing flexibility to accommodate expanding input requirements.

- Vertical Stacking Capability for Space Conservation: Supports vertical stacking on a DIN-rail, enabling efficient utilization of cabinet space, making it an ideal choice for installations with space constraints.

- Availability: Simplex Version Only: Currently, the board is available in a simplex version, catering to basic input requirements, with potential for future iterations to address more complex needs.

- Number of Channels: The board is equipped with 24 dry contact voltage input channels, providing extensive connectivity for various input sources and applications.

- Excitation Voltage: Operating with a nominal 24V DC excitation voltage, the board offers a floating configuration, with voltage ranging from 18 to 32V DC. This flexibility ensures compatibility with a wide range of power sources and system configurations.

- Input Current: The first 21 circuits draw a modest 2.5 mA each, exhibiting a resistance of 50 kohm. Meanwhile, the last three circuits demonstrate a slightly higher current draw of 10 mA each, corresponding to a resistance of 12.5 kohm. This distribution allows for efficient utilization of power while accommodating varying input requirements.

- Input Filter: Equipped with a hardware filter with a response time of 4 ms, it ensures reliable and accurate signal processing, mitigating potential noise and interference for precise data acquisition.

Characteristics

- Compactness: The board's compact design ensures minimal footprint, making it suitable for installations where space optimization is crucial.

- Mounting Flexibility: DIN-rail compatibility offers easy installation and integration, allowing to seamlessly integrate into existing setups.

- Abundant Inputs: With 24 contact inputs, the board provides versatility to accommodate various input sources, ensuring compatibility with diverse applications.

- Nominal Excitation: Operating at a nominal 24V DC excitation voltage, ensures consistent and reliable performance across different power supply configurations.

- Seamless Integration: A single cable connection simplifies setup, reducing complexity and enhancing overall system efficiency.

- Scalability: The ability to connect two boards offers scalability, enabling users to expand input capacity as needed to meet evolving requirements.

- Space Efficiency: Vertical stacking on a DIN-rail optimizes cabinet space, making the DCI board an ideal choice for installations with limited space availability.

- Version Availability: Currently, the board is available in a simplex version, providing a cost-effective solution for basic input needs.

- Temperature Rating: Operating within a temperature range of 0 to 60°C, the DTCI board maintains stable performance across a broad spectrum of operating conditions, ensuring reliability and consistency in diverse environments.

Fault Detection

The board features comprehensive fault detection mechanisms to enhance system reliability and performance. It monitors for:

- Loss of contact input excitation voltage, alerting users to potential power supply issues.

- Non-responding contact input in test mode, enabling proactive identification and troubleshooting of input channel anomalies.

- Unplugged cable detection, ensuring seamless operation by alerting users to connectivity issues.

WOC has the largest stock of Speedtronic Mark VI Spares and we can repair your faulty spares with a warranty. WORLD OF CONTROLS can also supply unused and rebuilt components backed up with a warranty. Our team of experts is available round the clock to support your urgent needs related to critical spares, contact us.

FREQUENTLY ASKED QUESTIONS

What is IS210DTCIH1AA?

It is a contact input terminal board and is part of the GE Speedtronic Mark VI gas turbine control system.

What is the purpose of the green LINK LED?

The green LINK LED, provided for each Ethernet port, indicates the presence of a valid Ethernet connection, ensuring network connectivity.

What does the yellow TxRx LED indicate?

The yellow TxRx LED, also provided for each Ethernet port, indicates when the pack is transmitting or receiving data over the respective port, offering real-time feedback on data transfer activity.

How do these LEDs contribute to system monitoring?

These LEDs offer quick visual feedback on pack power, status, network connectivity, and data transmission activities, aiding in system monitoring, troubleshooting, and maintenance efforts. They help operators quickly identify potential issues and ensure the smooth operation of the control system.