SPECIFICATIONS

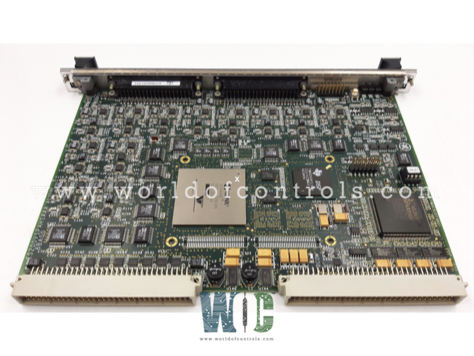

Part No.: IS200VSPAH1AAA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 7.0 in x 13.0 in

Product Type: monitoring card assembly

Availability: In Stock

Series: Mark VI

Functional Description

IS200VSPAH1AAA is a monitoring card assembly developed by GE. It is a part of Mark VI control system. The Mark VI turbine control system serves as the cornerstone of turbine operation, orchestrating a series of critical functions to ensure optimal performance, efficiency, and safety throughout the operational lifecycle. Mark VI turbine control system combines advanced control algorithms, real-time monitoring, and robust safety measures to deliver reliable and efficient turbine operation across a wide range of operating conditions. By fulfilling these core functions, the system optimizes performance, enhances grid stability, and safeguards both equipment and personnel, thereby contributing to the overall efficiency and reliability of power generation operations.

System Features

- Speed Control During Turbine Startup: The Mark VI system meticulously regulates turbine speed during startup sequences, ensuring a smooth and controlled acceleration process. By precisely adjusting fuel flow and other parameters, the system optimizes turbine startup for efficiency and reliability, mitigating potential stress on turbine components.

- Automatic Generator Synchronization: Automatic generator synchronization is a key feature of the Mark VI system, facilitating seamless integration of the turbine with the electrical grid. The system coordinates the synchronization process, aligning the turbine's output frequency and voltage with those of the grid to enable safe and efficient power transfer without disruption.

- Turbine Load Control During Normal Operation on the Grid: During normal operation on the grid, the Mark VI system exercises precise control over turbine load to match power generation with grid demand. By continuously monitoring grid conditions and adjusting turbine output accordingly, the system ensures optimal efficiency and stability while minimizing fluctuations in power output.

- Protection Against Turbine Overspeed on Loss of Load: Protection against turbine overspeed on loss of load is a critical safety feature provided by the Mark VI system. In the event of a sudden loss of load or grid disturbance, the system swiftly responds to prevent the turbine from exceeding safe operating speeds. By initiating emergency shutdown procedures and activating protective mechanisms, the system safeguards against potential damage to turbine components and ensures operator safety.

Control cabinet

- The control cabinet serves as a pivotal hub within the overall system architecture, housing essential control modules and facilitating seamless communication between various components. Whether configured with a single (simplex) Mark VI control module or three TMR (Triple Modular Redundant) control modules, its design ensures reliability and flexibility to meet the demands of industrial operations.

- Key components within the control cabinet include the control modules themselves, which play a central role in orchestrating system operations. In a simplex configuration, a single Mark VI control module governs system behavior, while in a TMR setup, three redundant control modules work in tandem to ensure fault tolerance and system reliability.

- These control modules are interconnected with their respective remote I/O devices via a high-speed I/O network known as IONet. Whether operating as a single or triple configuration, IONet facilitates rapid data exchange between the control modules and remote I/O devices, enabling real-time monitoring and control of critical system parameters.

- Furthermore, connectivity to the Unit Data Highway (UDH) is established through the controller Ethernet® port, enabling seamless integration with the broader system infrastructure. This connection ensures interoperability and coordination with other system components, facilitating streamlined data exchange and coordinated system operation.

- Flexibility is a hallmark of the control cabinet's design, with provisions for both local and remote I/O configurations. This versatility allows for adaptation to varying operational requirements and facilitates seamless integration into diverse industrial environments.

- Power requirements for the control cabinet include 120/240 V AC and/or 125 V DC power sources. These power inputs are converted to 125 V DC within the cabinet to supply power to the control modules, ensuring consistent and reliable operation under all conditions.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200VSPAH1AAA?

It is a monitoring card assembly developed by GE under the Mark VI series.

What role does the Mark VI turbine control system play in grid integration?

The system facilitates automatic synchronization of the turbine generator with the electrical grid, aligning frequency and voltage to enable safe and efficient power transfer without disruption.

How does the control system contribute to grid stability during normal operation?

The system continuously monitors grid conditions and adjusts turbine load to match power generation with grid demand, ensuring optimal efficiency and stability while minimizing fluctuations in power output.

What safety measures does the turbine control system provide in case of load loss or grid disturbance?

The system provides protection against turbine overspeed in the event of a sudden loss of load or grid disturbance by initiating emergency shutdown procedures to prevent damage to turbine components and ensure operator safety.