SPECIFICATIONS

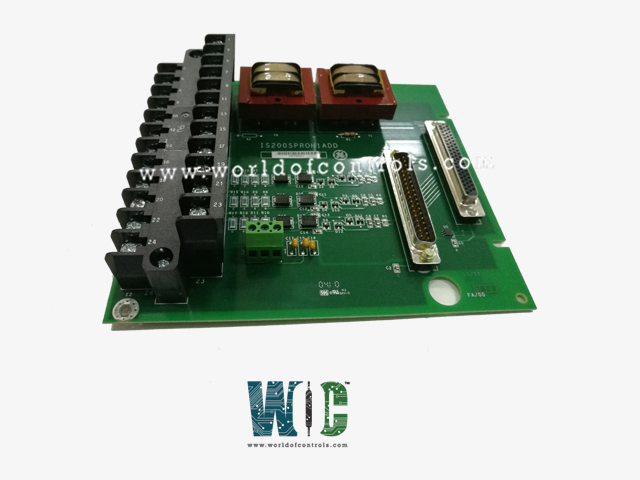

Part No.: IS200SPROH1ACC

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 15.9 cm high x 17.8 cm wide

Technology: Surface-mount

Temperature Operating: -30 to 65 oC

Product Type: Backup Protection Terminal Board

Availability: In Stock

Series: Mark VIe

Functional Description

IS200SPROH1ACC is a Backup Protection Terminal Board developed by GE. It is a part of Mark VIe control system. The Terminal Board serves as a crucial component within the system, facilitating the integration and functionality of various elements, particularly the PPRO I/O pack. Its design and configuration play a vital role in ensuring smooth operations and effective communication between different parts of the system.

PPRO I/O Pack Integration

- At the heart of the Terminal Board is the integration of the PPRO I/O pack, which serves multiple functions essential for the system's operation.

- One of its primary tasks is to condition speed signal inputs, ensuring that they are accurately processed and interpreted by the PPRO. Additionally, the PPRO I/O pack interfaces with other components of the system, contributing to its overall efficiency and performance.

Speed Signal Conditioning

- The Board is equipped with mechanisms to condition speed signal inputs, a critical process that ensures the accuracy and reliability of speed-related data.

- By conditioning these inputs, the board optimizes the performance of the PPRO, enabling it to effectively interpret and respond to speed-related information, thus enhancing the overall functionality of the system.

Potential Transformers (PTs)

- Integral to the functionality are the potential transformers (PTs), which are responsible for facilitating the input of bus and generator voltage data. Positioned strategically on the board, these PTs play a crucial role in providing accurate voltage inputs, which are essential for various operational aspects of the system, including monitoring and control.

Connector Configuration

- It features a DC-37 pin connector located adjacent to the PPRO pack connector.

- This configuration allows for seamless connectivity between the board and external devices, such as the Mark VIe backup trip relay terminal board. Through this connector, a cable is employed to establish a connection, facilitating communication and data transfer between the two components.

Mark VIe Backup Trip Relay

- The integration with the Mark VIe backup trip relay terminal board is facilitated through a cable connection to the DC-37 pin connector on the SPRO Terminal Board. This connection enables the exchange of essential data and signals between the two boards, enhancing the system's reliability and redundancy by providing backup trip functionality.

Terminal Mapping

- The terminals are meticulously mapped to accommodate various inputs and functions.

- Terminals 1-4 are designated for PT inputs, while terminals 19-24 are allocated for speed inputs. Additionally, terminals 7-15 are reserved for future control feature expansion and are routed to the JA1 PPRO connector, ensuring scalability and adaptability of the system.

Connector Routing

- To facilitate connectivity and compatibility, the reserved terminals (7-15) are routed to the JA1 PPRO connector.

- This routing ensures that any future control feature expansion can be seamlessly integrated into the system, enhancing its functionality and versatility without requiring significant modifications to the existing infrastructure.

Unconnected Terminals

- Terminals 5-6 and 16-18 on the Board do not have a board connection.

- While currently unused, these terminals may offer potential for future expansion or customization, providing flexibility for system upgrades or modifications as needed.

Connector Locations

- The JA1 and JA3 connectors provide designated locations for the connection of the PPRO and the trip terminal board cable.

- These connectors serve as pivotal points for establishing communication and data exchange between the SPRO board and external components, contributing to the seamless operation and integration of the system as a whole.

Generator and bus voltage sensors

- Two single-phase potential transformers (PTs) are employed, each designed to sense voltage and deliver a secondary output of a nominal 115 V rms. These PTs play a fundamental role in accurately measuring the voltage levels of both the generator and the bus in the system.

- One significant aspect of these voltage sensors is their low loading characteristics, with each input demanding less than 3 VA (volt-ampere) of loading. This low loading ensures minimal interference with the voltage being measured, maintaining the accuracy and reliability of the sensor readings.

- Furthermore, the allowable voltage range for synchronization purposes is specified to be between 75 and 130 V rms. This range indicates the acceptable voltage levels within which synchronization can occur effectively, ensuring proper coordination between different components of the system.

- Each PT input is equipped with magnetic isolation, featuring a 1,500 V rms barrier. This isolation serves to prevent unwanted electrical interference and ensures the safety of the system by effectively separating the input signal from the output signal. This barrier provides a robust protection mechanism, safeguarding against potential electrical hazards.

- Moreover, the system allows for flexibility in cable length, with the capability to accommodate up to 1,000 feet of 18 AWG (American Wire Gauge) wiring. This extended cable length capability facilitates the installation of the voltage sensors in various configurations, enabling optimal positioning for accurate voltage measurement while ensuring compatibility with the system's wiring requirements.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200SPROH1ACC?

It is a Backup Protection Terminal Board developed by GE under the Mark VIe series.

What is the purpose of the electronic ID parts on the board and backup trip relay terminal board?

The electronic ID parts serve to provide crucial information during power initialization. This data is read by the module to verify the presence of a valid hardware arrangement before normal operation begins.

How does the module utilize the information from the electronic ID parts?

The module utilizes the information to ensure that the hardware configuration of the system aligns with expectations. It confirms the integrity and compatibility of components connected to the SPRO board and backup trip relay terminal board.

What happens if the electronic ID parts are not recognized or found to be invalid during power initialization?

If the electronic ID parts are not recognized or are deemed invalid, the module may prevent the system from transitioning into normal operation mode. This precaution helps mitigate the risk of potential hardware conflicts or malfunctions.

Are the electronic ID parts configurable or replaceable?

Typically, electronic ID parts are not user-configurable or replaceable. They are pre-programmed components integrated during manufacturing. Any replacement or modification would likely require specialized knowledge and equipment, necessitating qualified personnel.