World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200IIDAG1A - Direct Current Innovation Board is available in stock which ships the same day.

IS200IIDAG1A - Direct Current Innovation Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200IIDAG1A - Direct Current Innovation Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

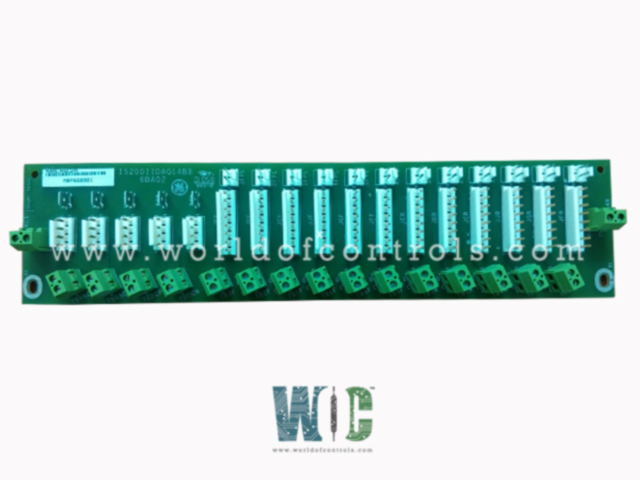

Part Number: IS200IIDAG1A

Manufacturer: General Electric

Series: EX2100

Product Type: Direct Current Innovation Board

Number of Input channels: 24

Power supply voltage: 28V dc

Technology: Surface Mount

Operating temperature: -30 to 65 °C

Size: 33.02 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS200IIDAG1A is a Direct Current Innovation Board manufactured and designed by General Electric as part of the EX2100 Series used in GE Excitation Control Systems. The Direct Current (DC) Innovation Board is a highly specialized control system used for managing and optimizing the performance of DC motors and drives in various industrial applications. It typically operates with a range of DC voltage inputs, such as 12V, 24V, or 48V, and is capable of handling varying current ratings depending on the specific system requirements. Powered by a high-performance microcontroller or a Digital Signal Processor (DSP), the board is designed for real-time operations, enabling advanced motor control and signal processing.

In terms of connectivity, the board supports widely used communication protocols like CANopen, Modbus, EtherCAT, and RS485, offering flexibility for system integration. It includes multiple digital and analog inputs and outputs, facilitating easy interaction with sensors and other peripheral devices. Motor control is achieved through Pulse Width Modulation (PWM) technology, which ensures smooth speed regulation and accurate torque control, while real-time feedback from encoders and tachometers ensures optimal motor performance.

BENEFITS:

WOC holds the largest inventory of OEM replacement parts for GE Excitation Turbine Control Systems. We also offer repair services for faulty boards and provide unused or refurbished boards with a warranty. Our expert team is available 24/7 to meet your OEM requirements. At WOC, we're ready to assist with all your automation needs. For pricing, availability, or inquiries about parts and repairs, please contact us via phone or email.

What types of motors can the DC Innovation Board control?

The DC Innovation Board can control standard DC motors, including brushed and brushless motors. It is compatible with a wide range of DC motor types, including permanent magnet (PM) motors, stepper motors, and other motor technologies that operate on DC power.

What communication protocols does the board support?

The board supports several industry-standard communication protocols, such as CANopen, Modbus TCP, EtherCAT, Profibus, Profinet, and RS485, ensuring flexibility for integration into various industrial control systems.

What is Pulse Width Modulation (PWM) used for in this system?

PWM is a technique used to control the speed and torque of DC motors. The DC Innovation Board uses PWM to efficiently regulate the power sent to the motor, resulting in smoother performance, reduced energy consumption, and improved motor control accuracy.