World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

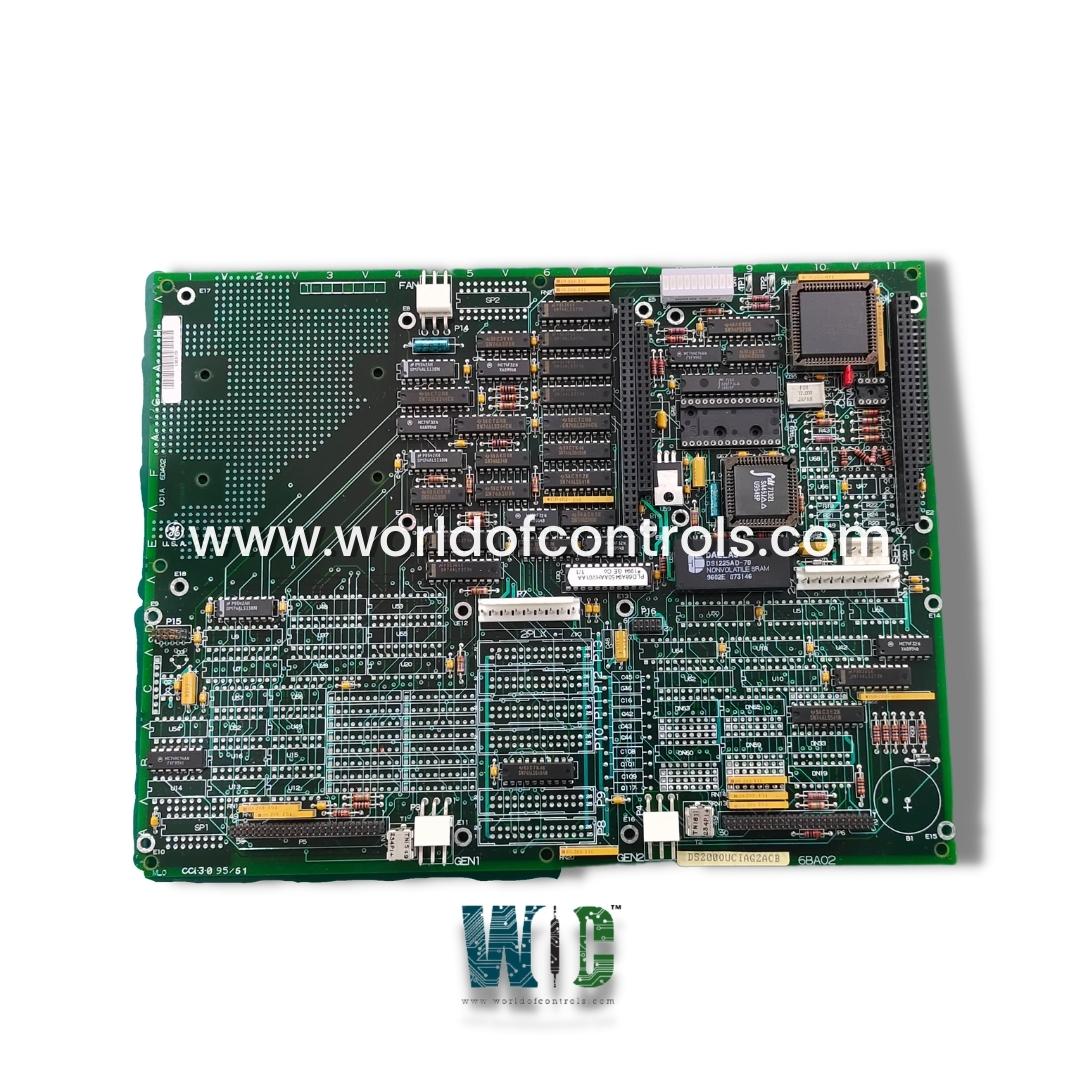

DS200UCIAG2ACB - Unit Controller Motherboard is available in stock which ships the same day.

DS200UCIAG2ACB - Unit Controller Motherboard comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200UCIAG2ACB - Unit Controller Motherboard, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200UCIAG2ACB

Manufacturer: General Electric

Series: EX2000

Product Function: Unit Controller Motherboard

Power Requirements: +5 V dc, 6 A

Number of relay channels: 12

Trip Solenoid Rating: 125 V dc

Power supply voltage: 28 V dc

Voltage Range: 18 - 32 VDC

Operating temperature: -30 to +65 degrees Celsius

Size: 15.9 cm high x 17.8 cm width

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

Manual: GEI-100198

FUNCTIONAL DESCRIPTION:

DS200UCIAG2ACB is a Unit Controller Motherboard manufactured and designed by General Electric as part of the EX2000 Series used in GE Excitation Control Systems. The UCIA is the main printed wiring board in the UC2000. It contains connectors that provide mounting for additional boards, such as the DS200UCPB and (GENI). The UCIA board contains one jumper, JP1, which is used for factory tests only. Test points, TP1 and TP2 are used for diagnostics when the process specifies. DN1 consists of LEDs defined by the process software. The fan connector (P14) connects 5V of power to the fan on the UCPB board.

FEATURES:

WOC has the largest stock of GE Excitation Control System Replacement Parts. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly contact our team by phone or email.

What are the key features of a unit controller motherboard in turbine control systems?

The key features include powerful processors for real-time control, redundancy and reliability features, analog and digital I/O interfaces, support for industrial communication protocols, high-speed data acquisition capabilities, safety mechanisms, extended temperature range operation, and scalability for future expansions.

Why is redundancy important in unit controller motherboards for turbine control?

Redundancy ensures system reliability and uptime by incorporating duplicate components such as processors and power supplies. This redundancy helps in mitigating the risk of single-point failures, which is critical in ensuring the continuous operation of turbines.

How does a unit controller motherboard communicate with other turbine control devices?

Unit controller motherboards use industrial communication protocols like Modbus, Profibus, CAN bus, or Ethernet/IP to communicate with sensors, actuators, and other control devices within the turbine control system. These protocols facilitate seamless data exchange and integration.