World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TURCF1ACB - Software EPROM Set is available in stock which ships the same day.

DS200TURCF1ACB - Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TURCF1ACB - Software EPROM Set, contact us and we will get back to you within 24 hours.

Part Number: DS200TURCF1ACB

Manufacturer: General Electric

Series: Mark V

Function: Software EPROM Set

Operating temperature: -35 to +55oC

Product Type: PCB

Country of Manufacture: United States (USA)

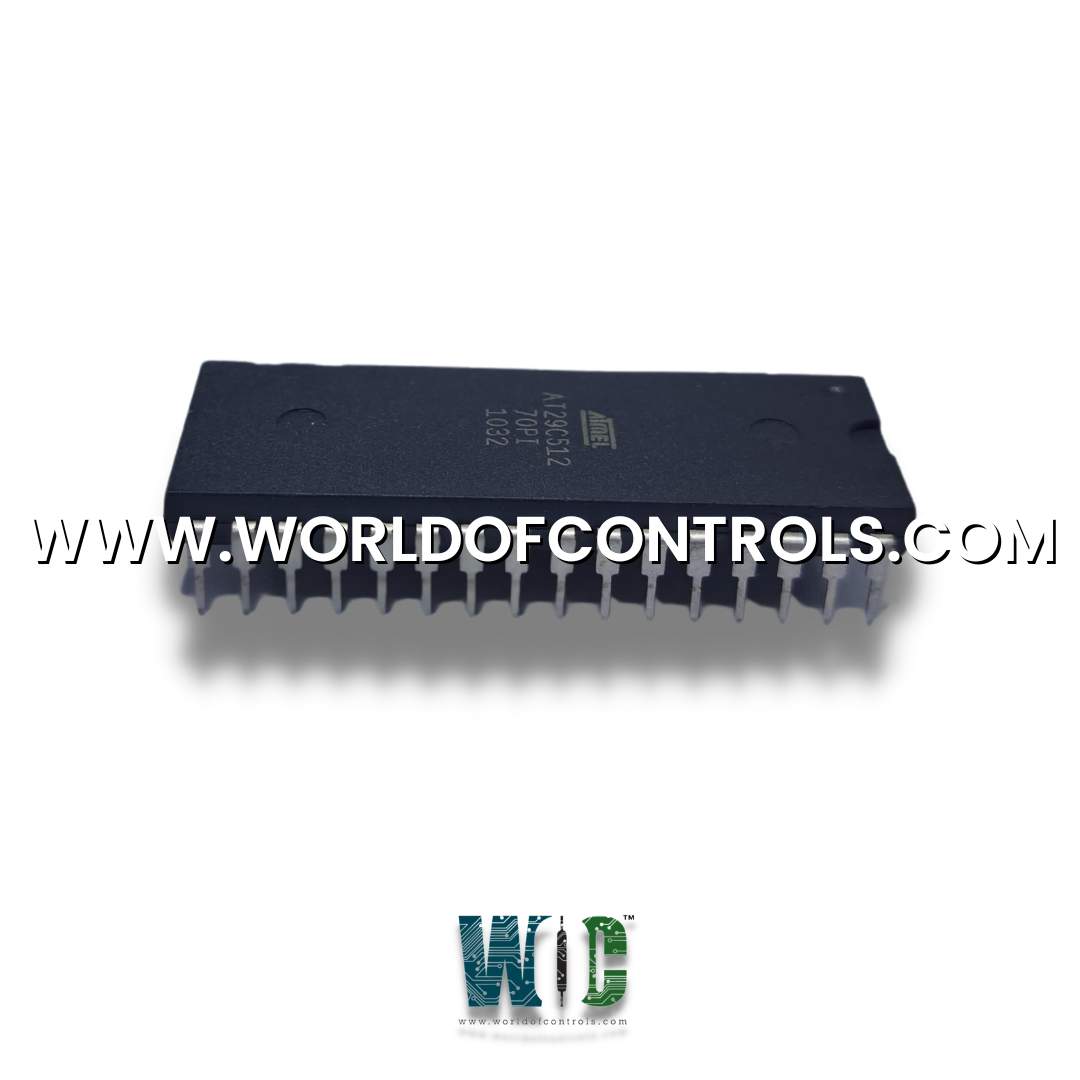

DS200TURCF1ACB is a Software EPROM Set manufactured and designed by General Electrics. It is a part of the Mark V Control System. EPROM, or Electrically Programmable Read-Only Memory, is a component in control systems, particularly for storing fixed memory. It provides a reliable and stable storage solution for firmware and essential data that do not require frequent updates. The data stored in EPROM is retained even when the system is powered off, ensuring the integrity of foundational software that governs system operations.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200TURCF1ACB?

It is a Software EPROM Set manufactured and designed by General Electrics.

Can adjustments to the system be made while it is operational?

Yes, operators can make certain adjustments, such as modifying control constants like gains and offsets, while the unit is online. However, these changes require entering a security code to ensure authorized access.

What is the role of the alarm management system within the operator interface?

The alarm management system provides real-time notifications of system issues, allowing operators to address them promptly. It also logs alarms for historical analysis and troubleshooting purposes.