World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TCQBF1BAD - Software EPROM Set is available in stock which ships the same day.

DS200TCQBF1BAD - Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCQBF1BAD - Software EPROM Set, contact us and we will get back to you within 24 hours.

Part No.: DS200TCQBF1BAD

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Software EPROM Set

Availability: In Stock

Series: Mark V

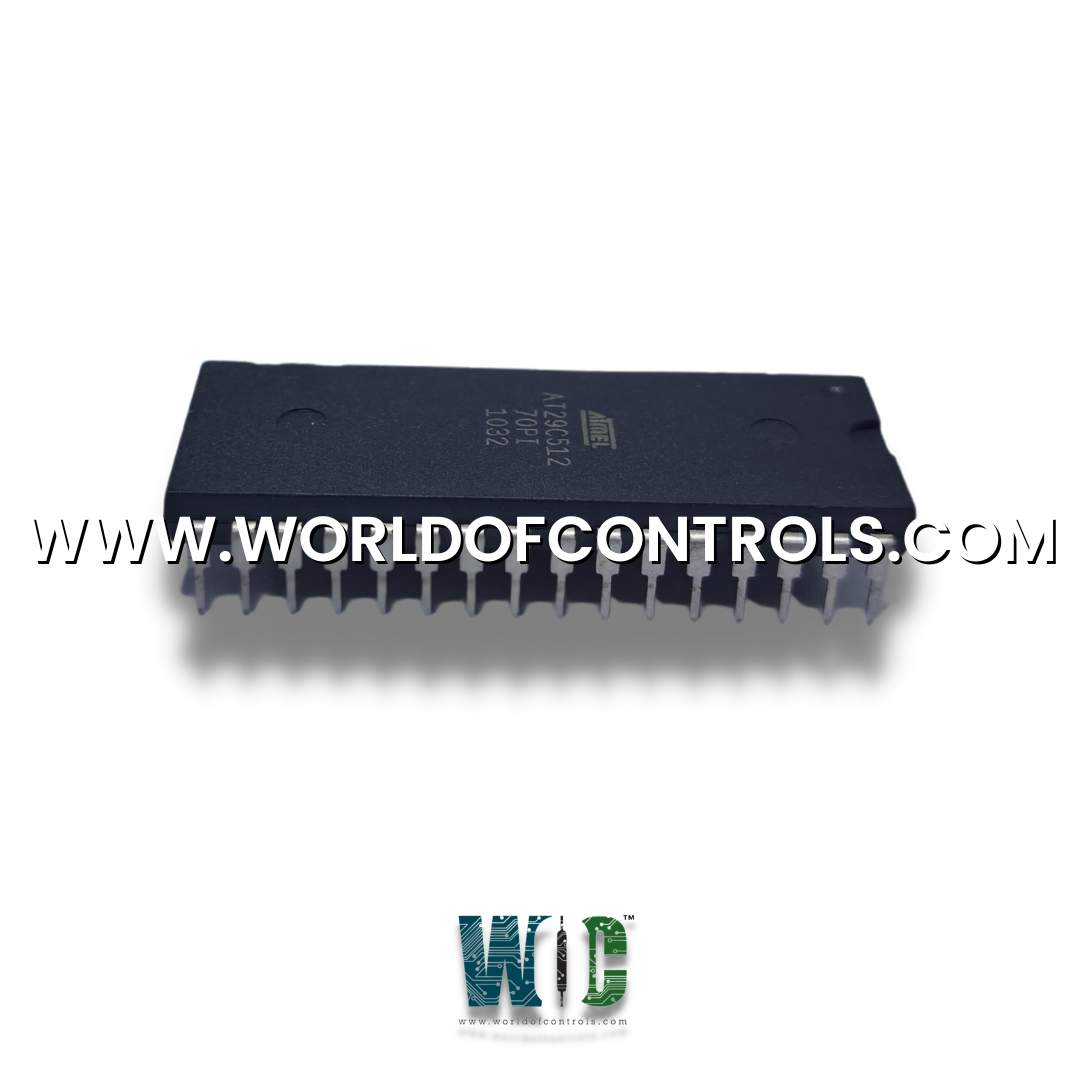

DS200TCQBF1BAD is a Software EPROM Set developed by GE. It is part of the Mark V series. A Software PROM Set is a collection of software programs and configurations stored in programmable read-only memory (PROM). It contains the necessary instructions and parameters for controlling and managing the operation of a specific control system or device.

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

What is DS200TCQBF1BAD?

It is a Software EPROM Set developed by GE under the Mark V series.

How does the diagnostic algorithm contribute to system reliability?

The diagnostic algorithm continuously monitors predefined deadbands for all analog inputs. If any input deviates from its deadband, indicating a potential fault, the algorithm triggers a diagnostic alarm. This proactive approach enables timely intervention to address issues and prevent system failures.

Why is fault tolerance important in industrial control systems like the Mark V?

Fault tolerance is crucial in industrial control systems to minimize the risk of system failures and disruptions in critical processes. It ensures operational continuity, enhances safety, and safeguards against potential financial losses due to downtime.

What are some benefits of using Software Voting in the control system?

Software Voting improves system reliability, enhances fault tolerance, and ensures consistent control performance. It mitigates the impact of software or hardware failures, contributing to overall operational efficiency and safety.