SPECIFICATIONS

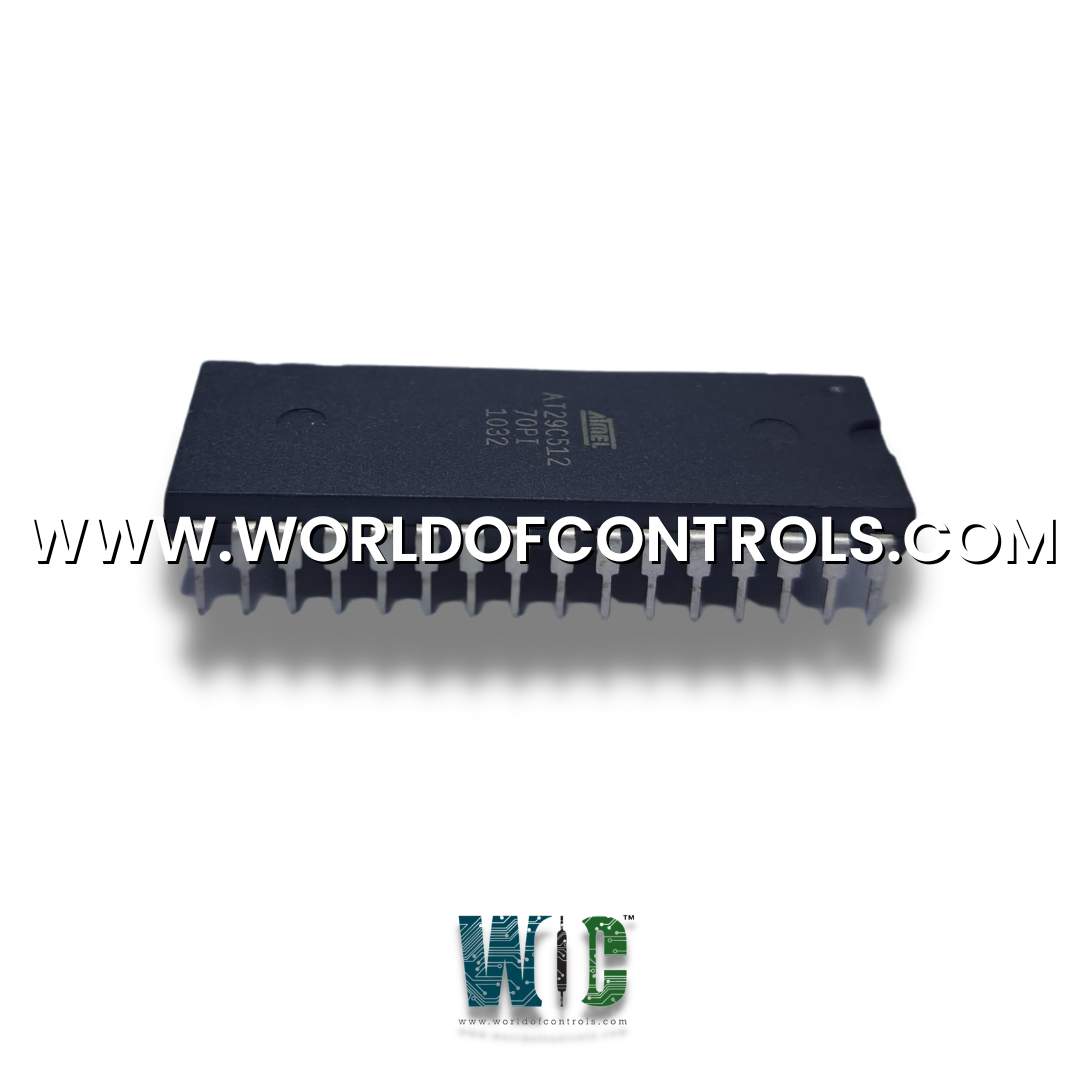

Part No.: DS200TCQBF1ABG

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Software EPROM Set

Availability: In Stock

Series: Mark V

Functional Description

DS200TCQBF1ABG is a Software EPROM Set developed by GE. It is part of the Mark V series. It is designed to support control processes, enhance system responsiveness, and maintain overall operational stability. It integrates seamlessly with other Mark V components, ensuring efficient data processing, real-time decision-making, and optimized turbine performance.

Features

- The Mark V system has rapidly proven its effectiveness through strong reliability and availability metrics, solidifying its position as a highly efficient and advanced turbine control solution. Building upon the proven success of the Mark IV system, the Mark V incorporates cutting-edge enhancements to further improve performance, diagnostics, and maintainability.

- One of the most significant upgrades in the Mark V system is its enhanced microprocessor technology, which enables faster processing speeds, improved data handling, and better system responsiveness. This advancement ensures that turbine operations are managed with higher precision and efficiency, reducing the likelihood of system failures and improving overall control performance.

- Additionally, the increased input/output (I/O) capacity allows the system to process a greater volume of operational data, supporting more complex turbine control functions and expanding compatibility with additional sensors and monitoring devices. This improvement enhances system adaptability across various turbine configurations and industrial applications.

- The integration of Software-Implemented Fault Tolerance (SIFT) technology further strengthens the system’s reliability. SIFT is a crucial component of the Mark V's architecture, designed to detect, isolate, and mitigate hardware or software faults in real time. By continuously monitoring system health and performing self-correction mechanisms, SIFT ensures seamless and uninterrupted turbine operations, reducing unplanned downtime and maintenance costs.

- Advanced diagnostic capabilities have also been incorporated into the Mark V system, providing operators with detailed system insights, predictive maintenance tools, and real-time fault detection. This enhancement significantly improves troubleshooting efficiency, allowing operators to identify and resolve issues quickly, minimizing disruptions and maximizing system uptime.

- Standardization and operator interface improvements in the Mark V design simplify system operation and maintenance. A more intuitive operator interface, featuring improved graphical displays and data visualization, enables users to monitor turbine performance and system status more effectively. This ensures quicker decision-making and enhanced control precision.

- Beyond technological advancements, the Mark V system is engineered for long-term reliability and ease of maintenance. The system’s modular design allows for quick component replacement and upgrades, reducing mean-time-to-repair (MTTR) and ensuring cost-effective maintenance strategies.

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

Frequently Asked Questions

What is DS200TCQBF1ABG?

It is a Software EPROM Set developed by GE under the Mark V series.

How does the Mark V system differ from the Mark IV?

The Mark V builds upon the success of the Mark IV by incorporating improvements in Microprocessor technology for faster data processing, Increased I/O capacity for better system scalability, SIFT technology for improved fault tolerance, Advanced diagnostics for predictive maintenance, and Enhanced standardization and operator interface for user-friendly control.

What is SIFT technology in the Mark V system?

Software-Implemented Fault Tolerance (SIFT) is a key feature in the Mark V system that detects, isolates, and mitigates hardware and software faults. It ensures continuous operation by automatically correcting errors and providing redundant protection.