SPECIFICATIONS

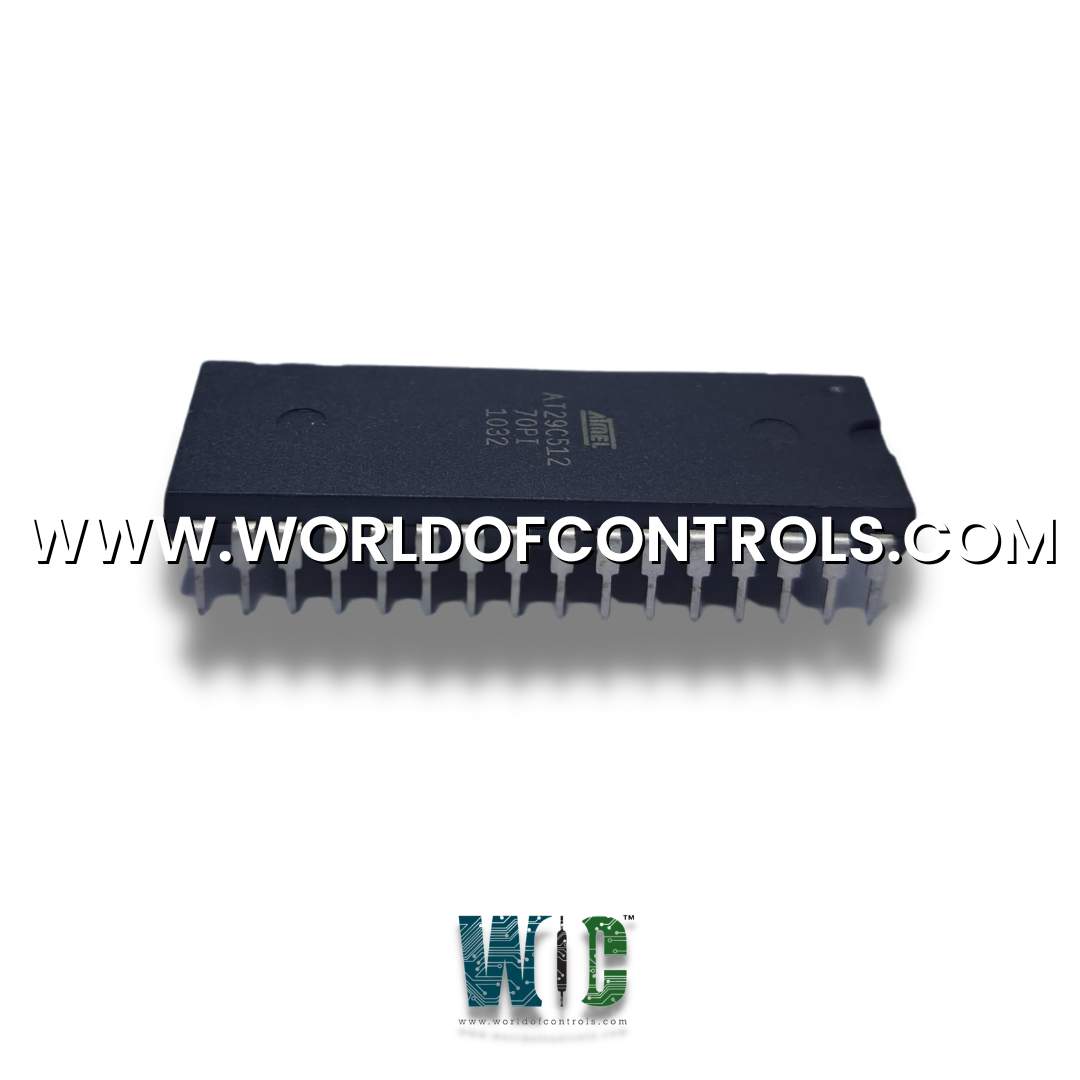

Part No.: DS200TCQAF1BBE

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65oC

Product Type: Software PROM Set

Availability: In Stock

Series: Mark V

Functional Description

DS200TCQAF1BBE is a Software PROM Set developed by GE. It is a part of Mark V control system. The EPROMs are carefully programmed with firmware that dictates how the Mark V system processes sensor inputs, adjusts control loops, and responds to faults. This ensures optimal turbine performance, energy efficiency, and operational safety.

Mark V Features

- Manages inlet guide vanes, which regulate the flow of air into the turbine. Adjusting these vanes optimizes turbine performance, enhances efficiency, and improves load response. For turbines equipped with emissions control technologies, such as Dry Low NOx (DLN) combustion, the system plays a vital role in fuel staging and combustion mode transitions. This ensures that emissions remain within environmental regulations while maintaining stable combustion, reducing pollutants such as nitrogen oxides (NOx) without compromising turbine performance. Additionally, when water or steam injection is used for emissions control, the Mark V precisely regulates the process to achieve the desired reduction in emissions.

- A critical aspect of the Mark V Control System is its ability to automate and sequence auxiliary systems, enabling fully automated startup, shutdown, and cooldown processes. This automation ensures that all necessary subsystems, such as lubrication, cooling, and fuel delivery, are activated in the correct sequence, preventing mechanical stress and ensuring smooth turbine operation. The system also monitors various parameters in real time, identifying potential issues before they escalate into failures. This includes detecting flame instability, monitoring overspeed conditions, and triggering protective actions to prevent damage to the turbine. The independent protection module provides an additional layer of security, ensuring immediate response to critical faults without relying solely on the main control processors.

- The operator interface of the Mark V Control System is designed to provide real-time feedback and allow easy interaction with turbine operations. It features a color graphic monitor that displays key performance data, alarms, and historical trends, enabling operators to monitor the health and efficiency of the turbine continuously. Commands are entered using a keyboard and a cursor positioning device, allowing for intuitive navigation and control. In addition, the system supports remote monitoring, enabling plant operators to access turbine data from a central control room or offsite location, further enhancing operational oversight and decision-making.

- By integrating advanced control algorithms, redundant protection mechanisms, and automated sequencing, the Mark V Control System ensures maximum reliability and efficiency. Its sophisticated fault detection capabilities, combined with automated corrective actions, help minimize downtime and extend the operational lifespan of gas turbines. This combination of automation, safety, and precision makes the Mark V a trusted solution for power plants and industrial facilities worldwide, where reliability and performance are of paramount importance.

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

Frequently Asked Questions

What is DS200TCQAF1BBE?

It is a Software PROM Set developed by GE under the Mark V series.

Does the Mark V support automated startup and shutdown?

Yes, the Mark V is designed for fully automated startup, shutdown, and cooldown sequences. It controls the activation of auxiliary systems such as fuel pumps, cooling systems, and lubrication systems to ensure smooth and safe turbine operation.

How does the Mark V handle emissions control?

For turbines using Dry Low NOx (DLN) combustion technology, the Mark V controls fuel staging and combustion modes to reduce emissions. It also manages water or steam injection systems when required for additional emissions control.