World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

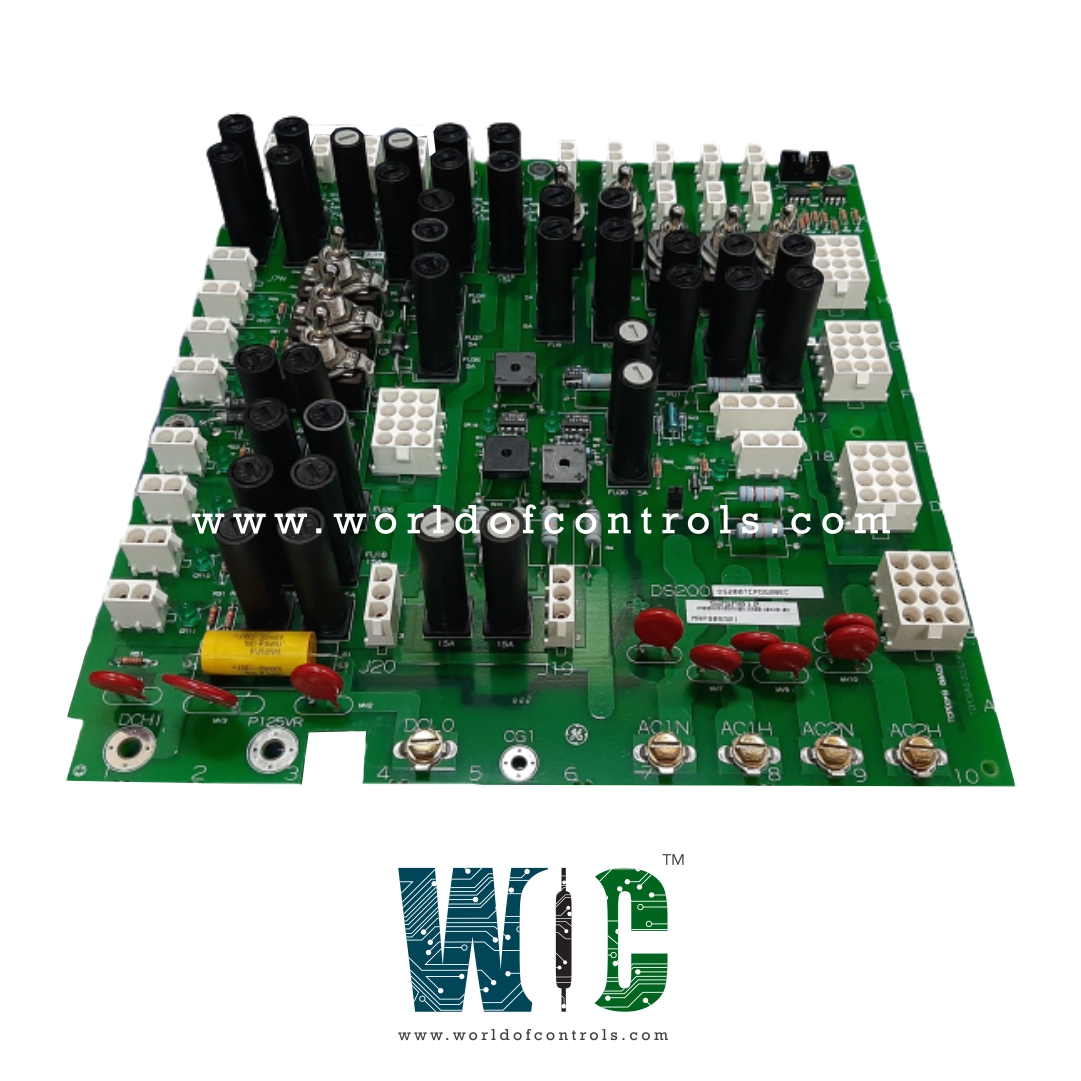

DS200TCPDG3B - Power Distribution Module is available in stock which ships the same day.

DS200TCPDG3B - Power Distribution Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCPDG3B - Power Distribution Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCPDG3B

Manufacturer: General Electric

Series: Mark V LM

Product Type: Power Distribution Module

Number of channels: 24

Power supply voltage: 28 V dc

Voltage Range: 14 to 32 V dc

Mounting: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to 65°C

Size: 30 cm high x 18 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCPDG3B is a Power Distribution Module manufactured and designed by General Electric as part of the Mark V LM Series used in GE Speedtronic Gas Turbine Control Systems. The Power Distribution Module (TCPD) in the core supplies 125 V dc power to the TCPS boards in each I/O core, the Control Engine core, and the TCEA boards in the core. The TCPD board includes switches for powering down each core individually. The digital I/O cores ( and ) are powered by their respective I/O cores and, rather than the core itself. The TCPD board provides power directly to the DTBA, DTBC, and DTBD terminal boards on the cores for solenoids and wetted contact inputs. The TCPD board supplies 120/240 V AC to the ignition transformers.

TCPD POWER:

The TCPD board is hardwired to receive external 115/230 V ac and 125 V dc power through TB1 on the

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does a Power Distribution Module enhance turbine control system performance?

By efficiently managing power distribution, a PDM helps optimize the performance of various turbine components. It ensures a consistent and reliable power supply, which is crucial for maintaining operational efficiency and safety.

What are the safety considerations when using a Power Distribution Module?

Safety is paramount when dealing with electrical systems. Proper installation, grounding, and insulation are essential to prevent electrical hazards such as shocks, short circuits, and fires. Regular maintenance and inspections also help ensure the continued safe operation of the PDM.

How does a Power Distribution Module contribute to system reliability and uptime?

By efficiently managing power distribution and incorporating features like fault detection and isolation, a PDM helps minimize the risk of system failures and downtime. This contributes to overall system reliability and ensures uninterrupted operation of the turbine.