World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TCDAF1BCI - EPROM Set is available in stock which ships the same day.

DS200TCDAF1BCI - EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCDAF1BCI - EPROM Set, contact us and we will get back to you within 24 hours.

Part No.: DS200TCDAF1BCI

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65oC

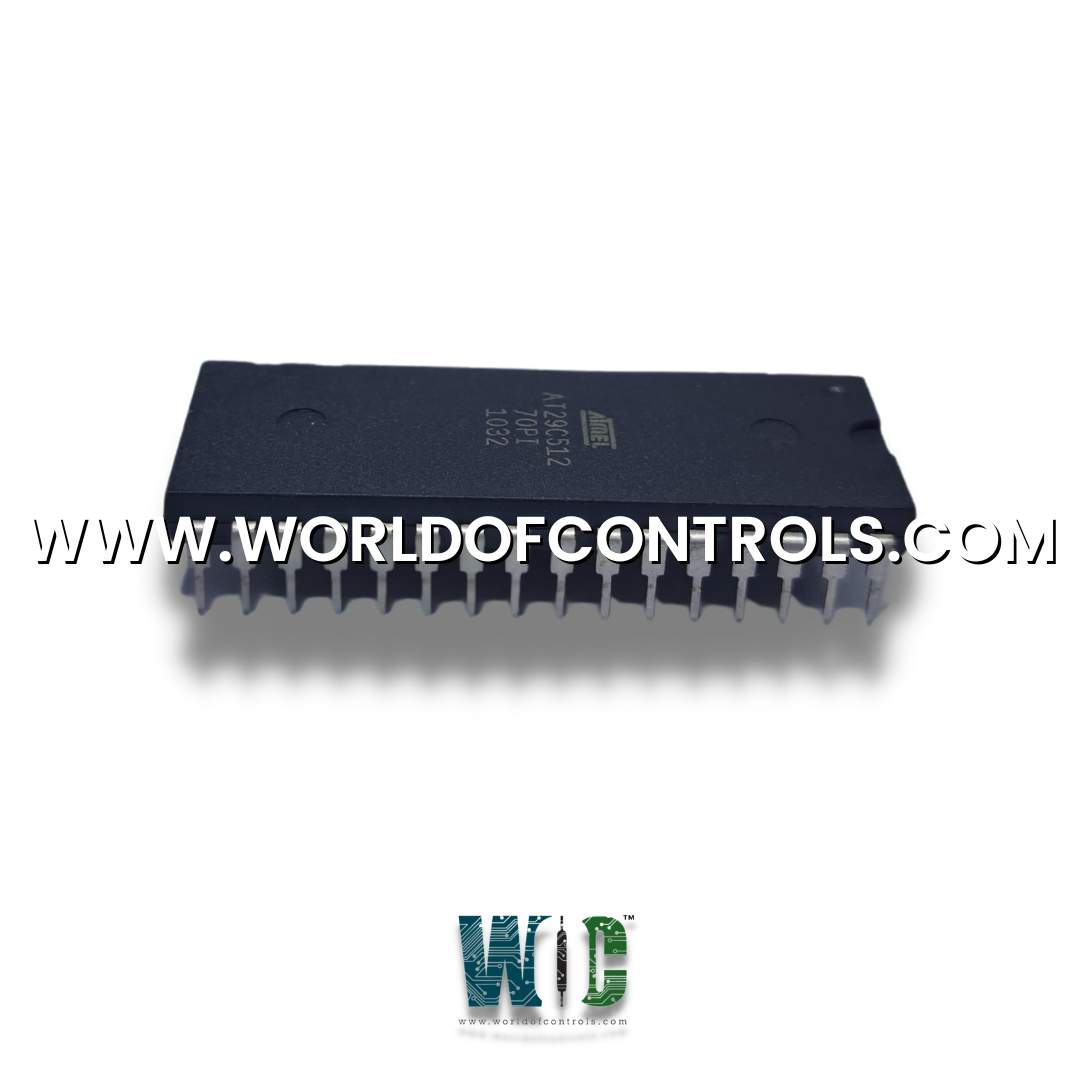

Product Type: EPROM Set

Availability: In Stock

Series: Mark V

DS200TCDAF1BCI is an EPROM Set developed by GE. It is a part of Mark V control system. This Erasable Programmable Read-Only Memory (EPROM) set is responsible for storing and retaining crucial firmware, control parameters, and system logic, ensuring the stable and efficient operation of turbines in power plants, industrial facilities, and energy production units.

To maximize system reliability and operational safety, the Mark V system employs multiple levels of redundancy:

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

What is DS200TCDAF1BCI?

It is an EPROM Set developed by GE under the Mark V series.

What is Software-Implemented Fault Tolerance (SIFT)?

SIFT is a fault-handling system that detects and corrects errors automatically to ensure turbine reliability.

How does the Mark V prevent failures?

It uses triple redundancy, two-out-of-three voting logic, and independent protection modules to prevent failures.