World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200SDCCG1A - Drive Control Card is available in stock which ships the same day.

DS200SDCCG1A - Drive Control Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200SDCCG1A - Drive Control Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

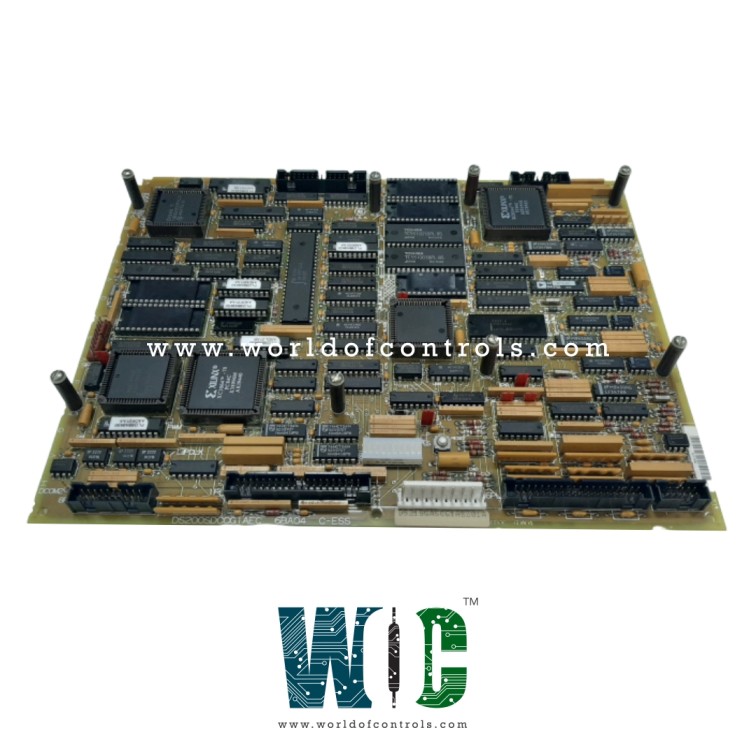

Part No: DS200SDCCG1A

Manufacturer: General Electric

Function: Drive Control Card

Series: Mark V

Operating temperature: -30 to 65°C

Board Size: 6.25 in x 4.25 in

Availability: In Stock

Country of Origin: USA

Manual: GEI-100029

FUNCTIONAL DESCRIPTION:

DS200SDCCG1A is a Drive Control Card manufactured and designed by General Electric as part of the Mark V series used in Speedtronic Control Systems. The Drive Control Card (SDCC), the main processor board, houses the electronics that control the EX2000 primarily. It comprises three dual-ported RAM-connected 16-bit microprocessors with related circuitry. It incorporates general-purpose interface circuitry that may be connected to other circuit boards to create different kinds of excitation systems. This interface circuitry manages the exciter and customer I/O. Two external dual-ported RAMs are also used to increase processing power.

The SDCC also has interface circuitry that joins with other boards to provide various ac and dc motor drive configurations. The interface circuitry regulates, processes, and controls drive, motor, and customer I/O signals. (In TC2000 applications, extra tasks are performed using the three primary microprocessors and the interface circuitry.) The three principal microprocessors of the SDCC are

DRIVE CONTROL PROCESSOR (DCP):

An 80C186 microcontroller (U1) uses both digital and analog I/O and has many built-in peripheral features. These features include the direct memory access (DMA) controller, timers/counters, an interrupt controller, wait-state generators, and address decoding for chip selects. User interfaces, external regulating loops (such as speed and location), and system-level operations make up DCP software.

SDCC CARD CONNECTIONS:

Eight connectors (marked _PL) connect the SDCC to the other controller boards and external signals. The positions of the connections are depicted in Figure 3 along with tables 3 through 9 that list the pin signals for each connector. The following are connectors to other boards:

SDCC CONFIGURATION:

HARDWARE: The SDCC has programmable hardware that needs to be configured appropriately for the application:

These jumpers are utilized for user application options or factory testing. The majority of the jumper options are pre-set at the factory. the data sheets for testing that come with each controller.

SOFTWARE: The SDCC requires the use of the ST2000, GE Control System Toolbox, or LynxOS Drive Configurator for any software modification, download, or replacement. For any software modifications, the ST2000, GE Control System Toolbox, or LynxOS Drive Configurator instruction book, a suitable PC, and the relevant drive/exciter instruction book are also needed.

WOC has the largest stock of GE Speedtronic Turbine Control System Replacement Parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Drive Control Card?

A Drive Control Card is an essential component in turbine and motor control systems, designed to regulate drive configurations, motor operations, and customer I/O signals. It plays a critical role in managing excitation systems and motor drives in industrial applications.

What does the Drive Control Card control?

The Drive Control Card manages various systems, including excitation systems, AC and DC motor drives, and customer input and output signals. Its functionality extends to controlling system-level operations and coordinating drive and motor configurations effectively.

What processors are on the Drive Control Card?

The card is equipped with three processors: the Drive Control Processor (DCP), the Motor Control Processor (MCP), and the Co-Motor Processor (CMP). The DCP handles system-level operations and external regulating loops, the MCP manages motor-specific tasks like AC/DC control and current regulation, and the CMP performs advanced calculations for complex motor control algorithms.