World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200MSTCF1BFF - Software EPROM Set is available in stock which ships the same day.

DS200MSTCF1BFF - Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200MSTCF1BFF - Software EPROM Set, contact us and we will get back to you within 24 hours.

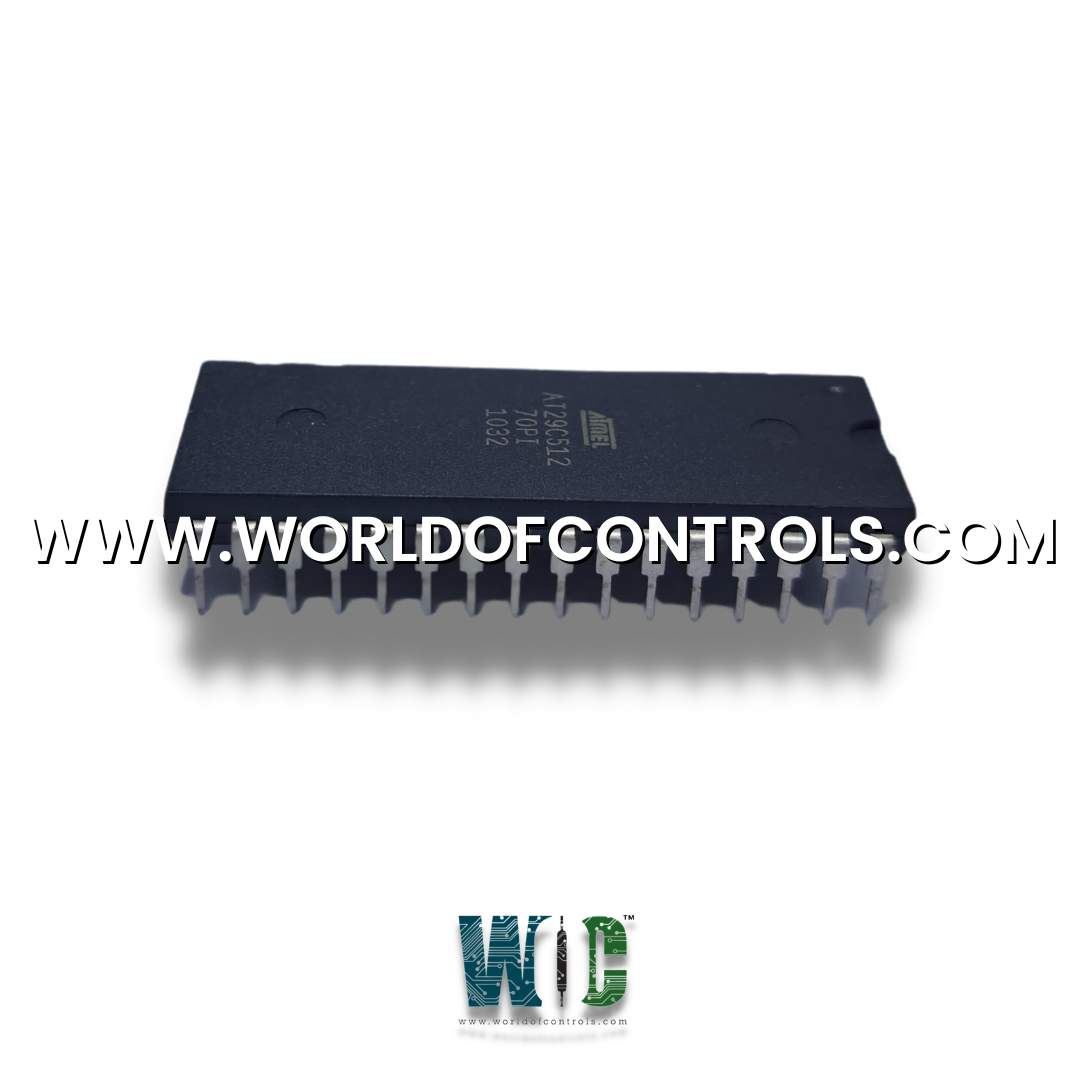

Part No.: DS200MSTCF1BFF

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Software EPROM Set

Availability: In Stock

Series: Mark V

DS200MSTCF1BFF is a Software EPROM Set developed by GE. It is a part of Mark V control system. The Mark V is an advanced turbine control system that can be fully programmed to cater to the intricate and dynamic requirements of the modern power generation industry, encompassing both gas and steam turbines. This flexible system offers state-of-the-art capabilities in control, monitoring, and protection, ensuring optimal performance and reliability in diverse operational conditions.

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

What is DS200MSTCF1BFF?

It is a Software EPROM Set developed by GE under the Mark V series.

What makes the Mark V turbine control system suitable for today's power generation industry?

The system is designed to handle the complex and dynamic behavior of both gas and steam turbines. Its fully programmable nature allows it to adapt to the diverse operational needs and challenges present in modern power generation facilities.

What are the key features of the Mark V turbine control system?

The Mark V system offers advanced capabilities in control, monitoring, and protection. It provides state-of-the-art functionalities that ensure efficient and reliable operation of turbines, enhancing overall performance and safety.

How does the Mark V system support programmability?

It allows for comprehensive programming to customize control strategies, monitor critical parameters, and manage protective functions tailored to specific turbine configurations and operational requirements.