World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

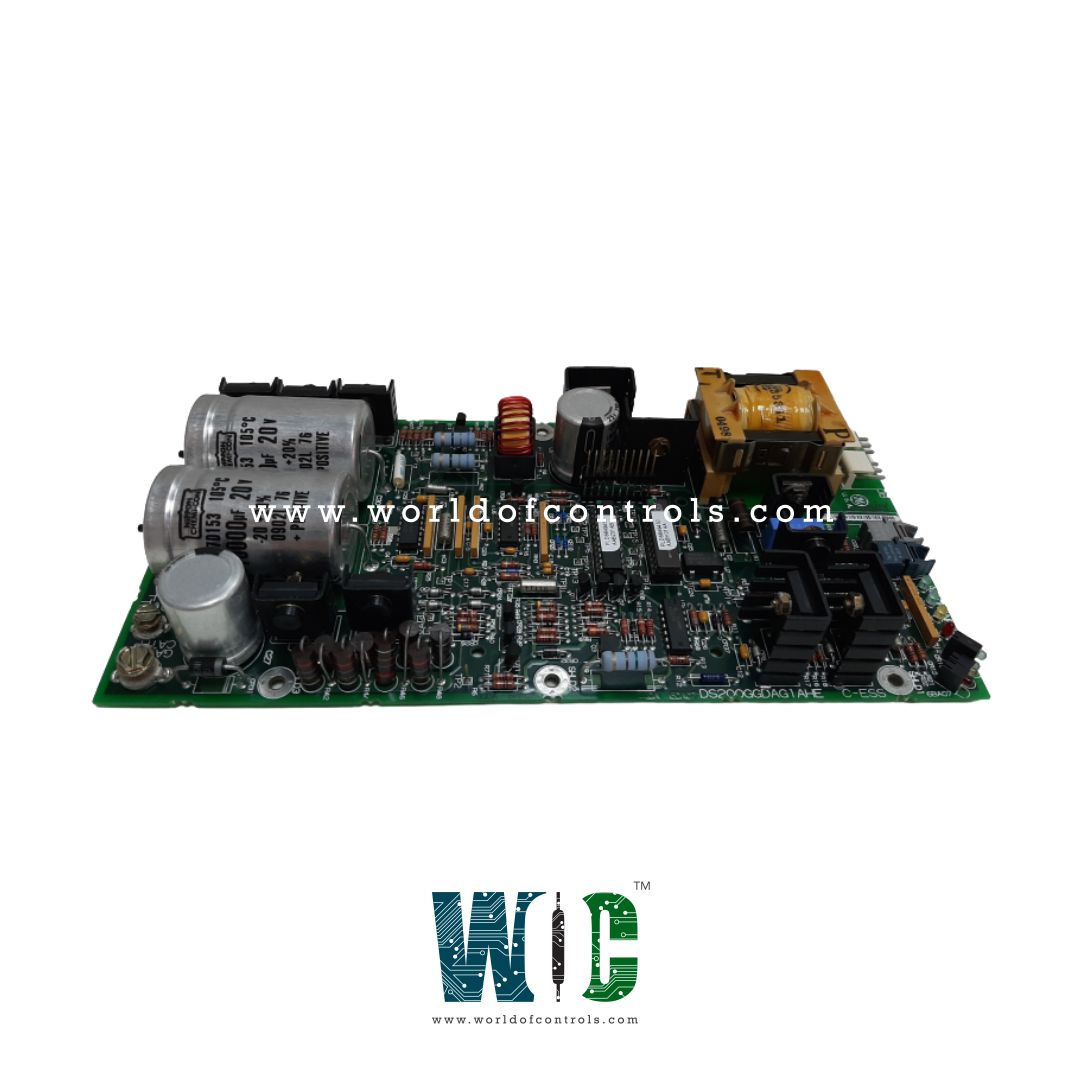

DS200GGDAG1A - GTO Gate Driver Board is available in stock which ships the same day.

DS200GGDAG1A - GTO Gate Driver Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GGDAG1A - GTO Gate Driver Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200GGDAG1A

Manufacturer: General Electric

Series: Drive Control

Product Type: GTO Gate Driver Board

Input Voltage: 12V, 15V, 24V

Switching Frequency: Up to 50 kHz

Gate Turn-On Voltage: 15V

Gate Turn-Off Voltage: -5V to -10V

Output Current: 1A - 5A

Output Voltage: 15V - 20V

Operating Temperature: -20°C to 85°C

Mounting Type: Surface Mount

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200GGDAG1A is a GTO Gate Driver Board manufactured and designed by General Electric as part of the Mark V Series used in GE Drive Control Systems. A GTO (Gate Turn-Off) Gate Driver Board is an essential component in power electronics systems that use GTOs (Gate Turn-Off thyristors) as switching devices. GTOs are semiconductor devices capable of handling high voltage and current, making them suitable for use in industrial applications such as motor drives, power inverters, and high-power converters. However, unlike traditional transistors, GTOs cannot be easily turned off by simply removing the gate voltage; they require a specific gate signal to be turned off. This is where the Gate Driver Board plays a crucial role, as it provides the necessary control and protection to ensure the GTO operates efficiently and reliably.

The primary function of the GTO Gate Driver Board is to supply the correct voltage and current to the gate of the GTO, turning it on and off as needed. It takes low-level control signals from a microcontroller or other control systems and amplifies them to the appropriate levels needed to switch the GTO. This includes shifting the gate signal to the high voltage required by the GTO to initiate conduction and then providing a signal to turn it off when necessary. The board must ensure that these switching actions occur at the correct times, as improper timing can lead to inefficiency, increased power loss, or even damage to the components.

FUNCTIONS OF GTO GATE DRIVER BOARD:

WOC has the largest stock of GE Drive Control System Replacement Parts. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a GTO Gate Driver Board?

A GTO (Gate Turn-Off) Gate Driver Board is an electronic circuit that controls the switching of a GTO (Gate Turn-Off) thyristor. It provides the necessary gate voltage to turn the GTO on and off, ensuring efficient operation in high-power applications.

What does a GTO Gate Driver Board do?

The main function of the GTO Gate Driver Board is to amplify low-level control signals and provide the required high voltage and current to the gate of the GTO. It ensures proper timing for turning the GTO on and off and also includes protection circuits to prevent damage from overvoltage, overcurrent, or thermal overload.

Why is a Gate Driver Board necessary for GTOs?

GTOs require specific gate signals for proper operation, including a high voltage to turn on and a negative pulse to turn off. The Gate Driver Board is necessary to provide these signals, as well as to protect the GTO from potential damage by managing the timing and voltage levels.