World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200GASCF1AEG - GE Software PROM Set is available in stock which ships the same day.

DS200GASCF1AEG - GE Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200GASCF1AEG - GE Software PROM Set, contact us and we will get back to you within 24 hours.

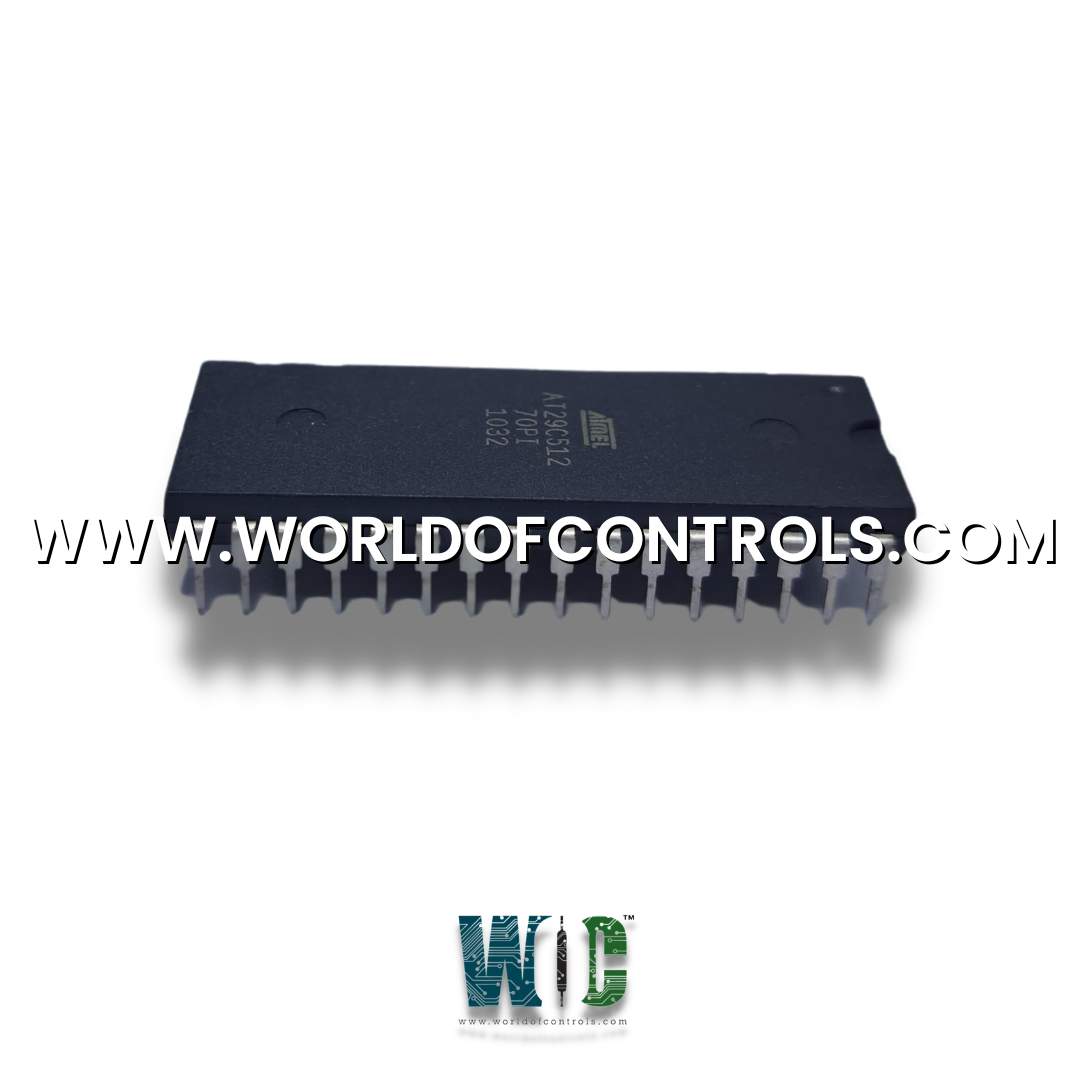

Part Number: DS200GASCF1AEG

Manufacturer: General Electric

Series: Mark V

Product type: GE Software PROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200GASCF1AEG is a GE Software PROM Set designed and developed by GE. It is a part of the Mark V control system. The system represents a highly adaptable turbine control system meticulously crafted to address the intricate and ever-evolving demands of today's power generation industry, particularly in managing the complex and dynamic behaviors exhibited by gas and steam turbines. This system is characterized by its remarkable flexibility and its capability to provide cutting-edge control, monitoring, and protection functions.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200GASCF1AEG?

It is a GE Software PROM Set designed and developed by GE

What is the role of the C controller in the configuration?

The C controller serves as an interface for non-critical and non-trip I/O (input/output). It allows operators to interact with the system, perform maintenance tasks, and execute adjustments like changing control constants, editing application software, modifying I/O assignments, and configuring display settings.

How is the modular design of the microprocessor-based controllers beneficial?

The controllers have a modular design, making maintenance more straightforward. Each module includes up to five boards, including a power supply. Multiple microprocessors are strategically allocated to handle different tasks, enhancing overall system performance.

How is communication handled among the controllers in the TMR configuration?

Communication between controllers occurs through high-speed ARCNET links, facilitating efficient data exchange within the system.

What is the primary objective of the TMR configuration's design?

The TMR configuration is designed to optimize performance, maintain system integrity, and provide operators with a robust interface for control and maintenance functions. This comprehensive approach enhances the reliability and functionality of the turbine control system.