World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DSPAF1ABE - Software EPROM is available in stock which ships the same day.

DS200DSPAF1ABE - Software EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DSPAF1ABE - Software EPROM, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

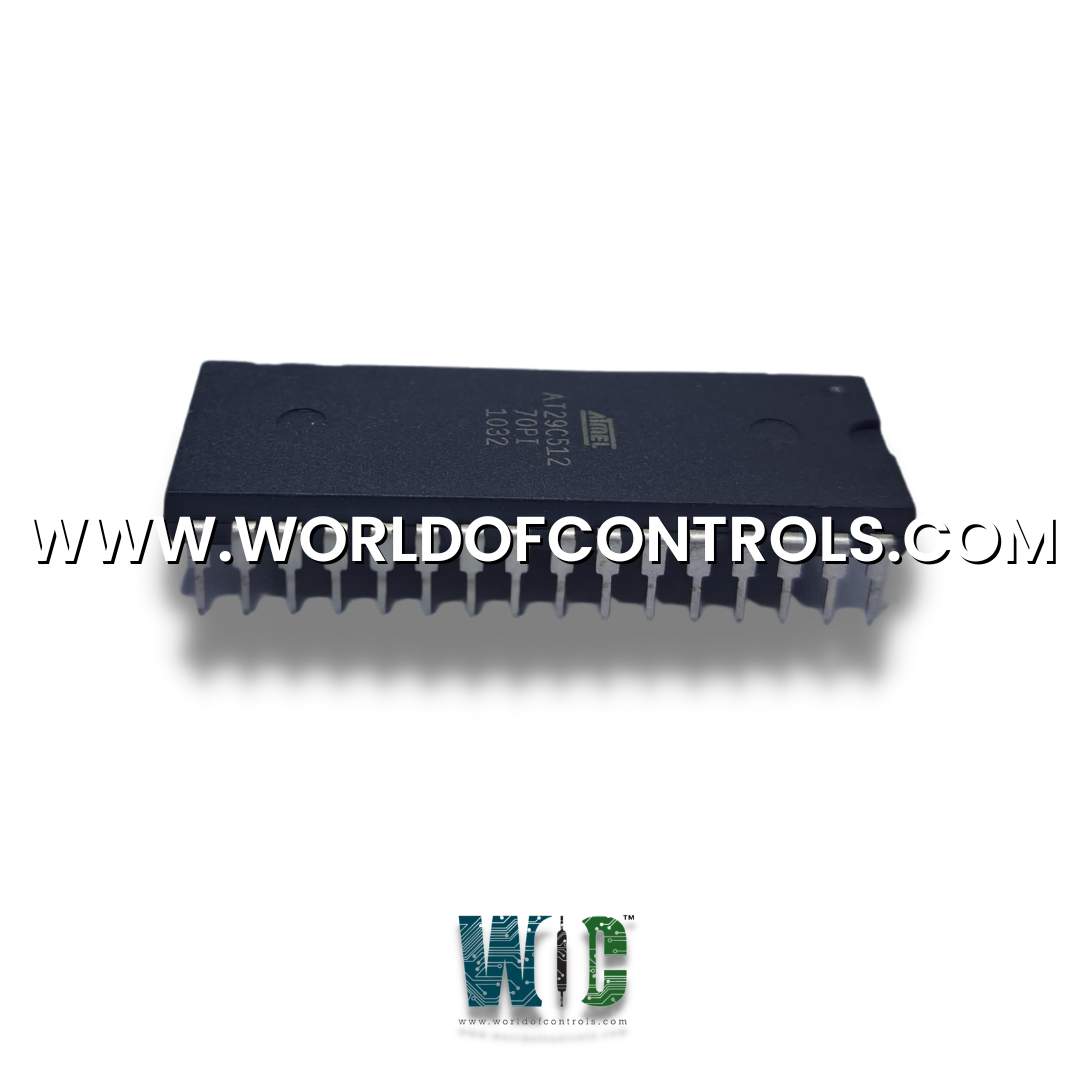

Part Number: DS200DSPAF1ABE

Manufacturer: General Electric

Series: Mark V

Product Type: Software EPROM

Operating temperature: -30 to 55 °C

Size: 8.25 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200DSPAF1ABE is a Software EPROM manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. These EPROM sets store and execute software programs that control and regulate critical functions within control systems. The specific functionality and purpose of the EPROM may vary depending on the system it is installed in. Such sets are designed to ensure these systems' efficient and reliable operation, contributing to their precision and performance. Analog controls have played a pivotal role in the history of control systems, particularly in the context of steam turbines. General Electric (GE) introduced steam turbines' electro-hydraulic control (EHC) system in the 1960s. These analog control systems represented a significant step forward in the evolution of turbine control. Let's explore the evolution of analog controls and their significance in more detail:

SYSTEM ANALOG CONTROLS:

WOC has the largest stock of GE Speedtronic Gas Turbine Control System Replacement Parts. We can also repair your faulty boards. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How did EHC systems evolve with the introduction of integrated circuitry (IC) technology?

In the 1970s, EHC systems transitioned to modernize their analog circuitry with integrated circuitry (IC) technology. This transition enhanced system efficiency and reliability, and solid-state logic circuits were introduced for protection and logic functions.

What was the EHC Mark II, and how did it improve steam turbine controls?

The EHC Mark II represented a significant advancement. It featured many IC components and a redesigned cabinet arrangement, resulting in improved overall efficiency and reliability in steam turbine controls.

How did the EHC Mark III incorporate digital elements into analog controls?

The EHC Mark III, primarily used for small- and medium-sized turbines, further embraced IC technology throughout the system. It also integrated electronic speed sensing and microprocessors for automation, reflecting the transition of digital elements into analog controls.