World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DMCBF1CIA - GE Software EPROM Set is available in stock which ships the same day.

DS200DMCBF1CIA - GE Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DMCBF1CIA - GE Software EPROM Set, contact us and we will get back to you within 24 hours.

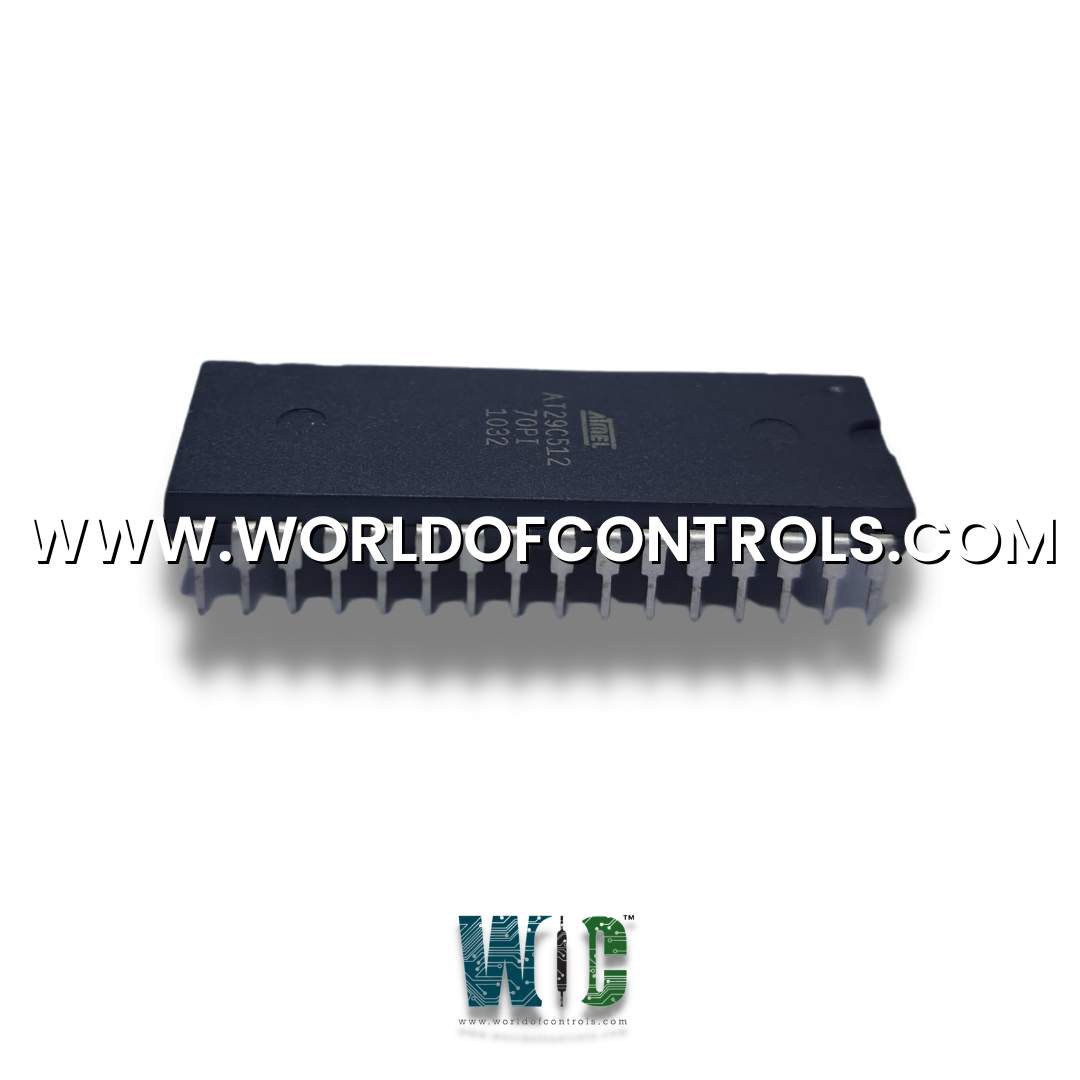

Part Number: DS200DMCBF1CIA

Manufacturer: General Electric

Series: Mark V

Product type: GE Software EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DMCBF1CIA is a GE Software EPROM Set designed and developed by GE. It is a part of the Mark V control system.�These EPROM sets contain firmware or software code that governs the functioning of the control system, including the algorithms for managing turbine operations, safety functions, data acquisition, and communication with other control and monitoring systems. These sets are integral to the system's reliability, safety, and performance.

The transition to digital control systems, exemplified by the Mark V digital systems, brings a host of benefits and improvements to industrial and power generation processes. These advantages are a result of the shift from hardware-based controls to software-based controls, offering greater flexibility and precision. Here's an in-depth exploration of the benefits of digital controls:

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200DMCBF1CIA?

It is a GE Software EPROM Set designed and developed by GE

How does flexibility play a significant role in digital control systems?

Flexibility is a key benefit because systems rely on software, enabling easy customization and adaptation to changing operational requirements. This adaptability makes digital systems versatile for a wide range of applications and scenarios.

How do digital control systems achieve greater precision in industrial processes?

They�use software-based control algorithms that can operate with extreme accuracy. This precision enables tighter control over critical parameters such as temperature, pressure, and speed, which enhances process efficiency and product quality.

What is the significance of CRT operator interfaces in systems?

CRT operator interfaces, featuring visual displays, provide real-time data, visual representations, and intuitive controls. This empowers operators to monitor, manage the system effectively, respond to alarms, and make informed decisions, contributing to safer and more efficient operations.

How do data link interfaces benefit control systems?

Data link interfaces allow digital control systems to establish connections with higher-level plant control systems. This connectivity promotes efficient data exchange and coordination among various components of the plant, enhancing overall system efficiency.

Can digital control systems continue to operate during repair or maintenance operations?

Yes,�it often incorporates online repair capabilities. In triple-redundant systems, for instance, the system can continue to operate while maintenance is in progress. This minimizes downtime and maximizes system reliability, ensuring uninterrupted industrial processes.