World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

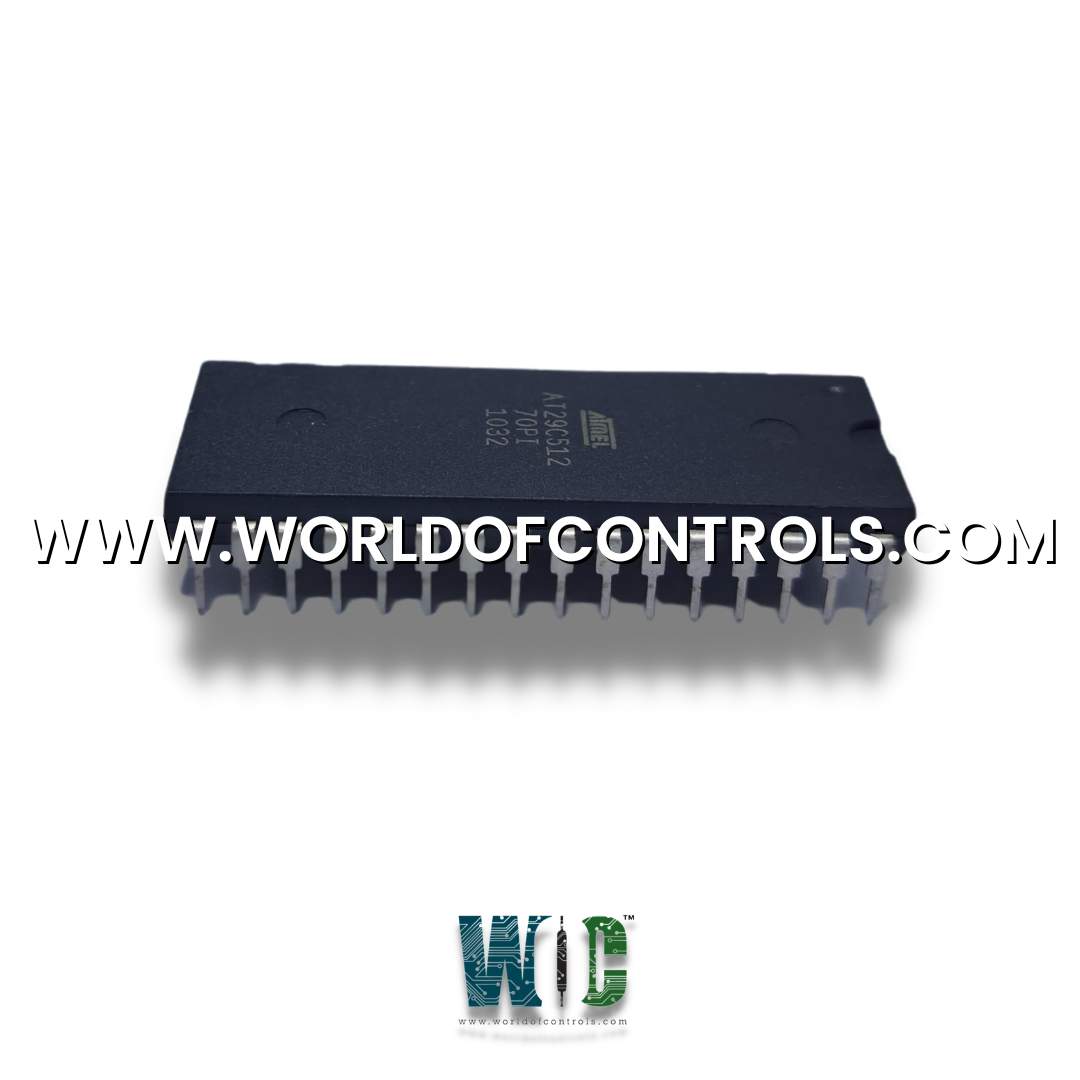

DS200DENQF1BDB - Software EPROM Set is available in stock which ships the same day.

DS200DENQF1BDB - Software EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENQF1BDB - Software EPROM Set, contact us and we will get back to you within 24 hours.

Part Number: DS200DENQF1BDB

Manufacturer: General Electric

Series: Mark V

Product type: Software EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENQF1BDB is a Software EPROM Set designed and developed by GE. It is a part of Mark V control system.�Mark V Control System is a sophisticated and versatile control system used in industrial applications, particularly in power generation and turbine control. It combines advanced technology, open architecture, robust memory management, communication capabilities, and a range of safety features to deliver precision, reliability, and adaptability in critical industrial processes.�

In the realm of large steam turbine applications, the management of power load unbalance emerges as a critical concern. Addressing this challenge necessitates specialized monitoring and protective measures. To fulfill this crucial role, a dedicated module known as PLU, an analogue to the P module, is harnessed. PLU, an acronym for Power Load Unbalance, assumes the central stage in mitigating power load irregularities and interfaces seamlessly with the fast closing features associated with control and intercept valves. The heart of this operation is a trio of autonomous cards, each bearing the designations U, V, and W. These cards assume a pivotal role in the detection and alleviation of power load unbalance, thereby upholding the safe and efficient operation of the expansive steam turbine system.

In the intricate domain of turbine and generator control systems, a substantial portion of the Input and Output (I/O) functionalities is devoted to the monitoring of diverse parameters. This non-redundant I/O framework finds its diligent overseer in the form of Module C, aptly termed the Common I/O module.

Within this operational landscape, versatile thermocouples emerge as indispensable sensors. Some thermocouples wear multiple hats, their roles extending beyond conventional control and protection functions. In addition to these vital roles, they actively partake in monitoring tasks that contribute to the overall health and performance of the system. These multi-faceted thermocouples, typically harnessed for critical activities like rotor stress calculations, establish direct connections with designated controllers such as R, S, and T.

However, not all thermocouples bear the dual responsibility of control and protection. A subset of thermocouples is reserved exclusively for monitoring purposes. These sensors, exemplified by measurements like thrust bearing oil drain temperature, may not directly influence the core control or protection mechanisms of the system. Nonetheless, they assume a crucial role in monitoring the overall health and performance of the turbine-generator system. This exclusive cohort of monitoring-only thermocouples finds its home within the C module, ensuring that their data is not only readily accessible but also available for thorough assessment and analysis. In this manner, they play a pivotal role in enhancing the overall efficiency and maintenance of the expansive turbine-generator system.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENQF1BDB?

It is a Software EPROM Set designed and developed by GE

What is the role of the PLU Module in the control system?

The Power Load Unbalance (PLU) Module is a dedicated component within the Mark V control system used in large steam turbine applications. Its primary function is to detect and mitigate power load unbalance, a critical concern in such systems. The PLU Module interfaces with control and intercept valves to ensure safe and efficient turbine operation.

How does the Common I/O (Module C) contribute to turbine and generator control systems?

Module C, known as the Common I/O module, oversees a significant portion of Input and Output (I/O) functions in turbine and generator control systems. It is responsible for monitoring various parameters, enhancing system reliability, and contributing to efficient system operation.

What is the significance of thermocouples in control systems within the system?

Thermocouples are versatile sensors used for monitoring and control functions in the Mark V control system. Some thermocouples serve dual roles, providing control and protection while also participating in monitoring tasks to ensure the system's overall health and performance.

Why are monitoring-only thermocouples essential?

Monitoring-only thermocouples are exclusively used for monitoring specific parameters in the Mark V control system, such as thrust bearing oil drain temperature. While they do not directly impact control or protection, they play a crucial role in assessing the overall system's health and performance, contributing to system efficiency and maintenance.