World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENCF1BDC - Software PROM Set is available in stock which ships the same day.

DS200DENCF1BDC - Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENCF1BDC - Software PROM Set, contact us and we will get back to you within 24 hours.

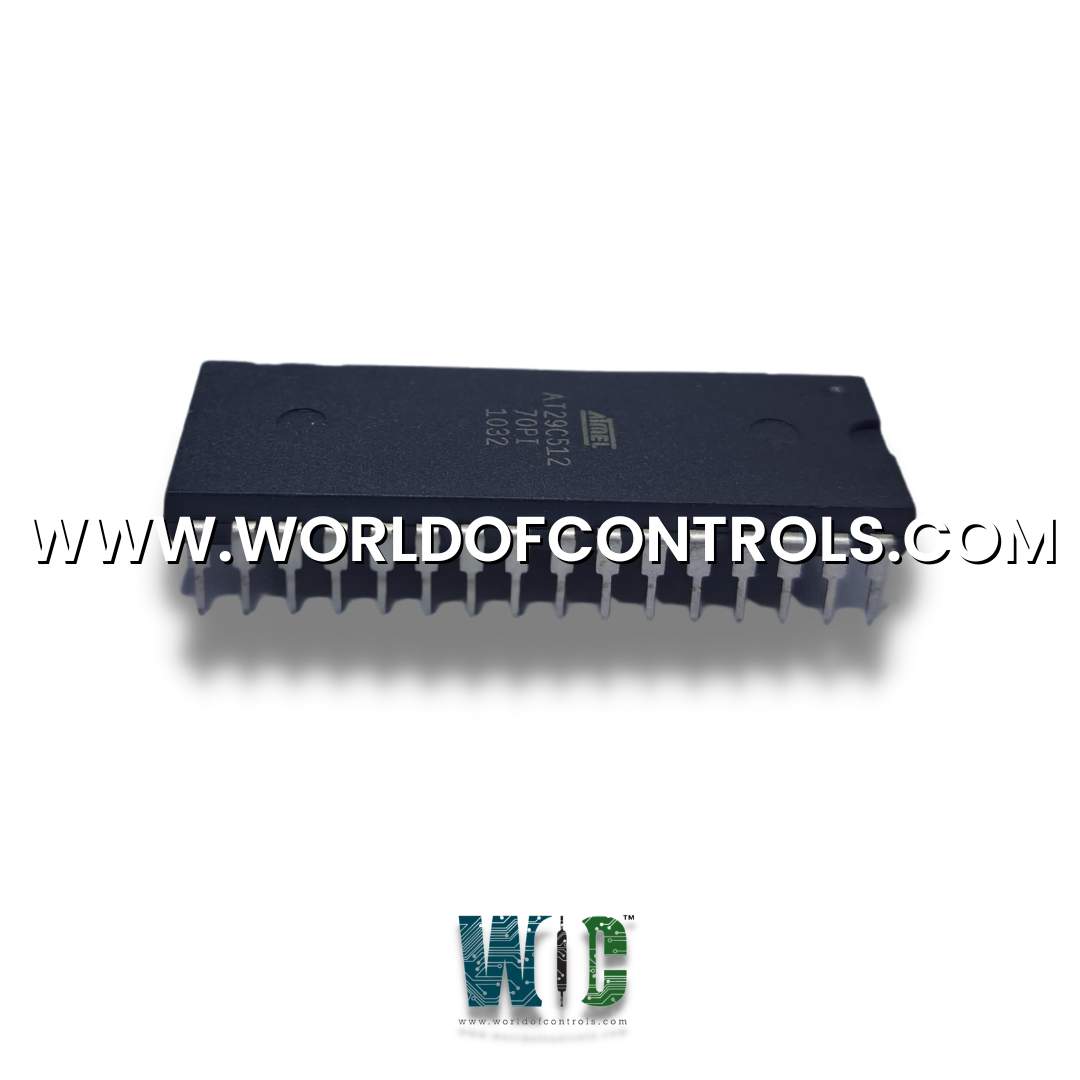

Part Number: DS200DENCF1BDC

Manufacturer: General Electric

Series: Mark V

Product type: Software PROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENCF1BDC is a Software PROM Set designed and developed by GE. It is a part of Mark V control system. The control system has embraced advanced microprocessors to a greater extent, featuring an improved system structure. It employs SIFT technology for control, incorporates a new triple-redundant protective module, and boasts substantial hardware diagnostic enhancements. With standardized modular construction, it achieves superior quality, quicker installation, heightened reliability, and streamlined online maintenance procedures.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENCF1BDC?

It is a Software PROM Set designed and developed by GE

Could you explain the voting process used in the Mark V Control System, and why is it important?

Once the information is on the DENET, each processor retrieves three values and conducts a two-out-of-three software vote. This process ensures consistency in data interpretation and is vital for accurate control signal interpretation.

How are voting mismatches detected in the Mark V Control System, and what happens when they occur?

Any voting mismatches among the cores are identified by the DCC card in the C core. When a mismatch is detected, the system generates a diagnostic alarm, indicating a potential issue that requires attention.

Is there a parallel between how analog signals and digital signals are handled in the control panel?

Yes, the process of handling analog signals is similar to the way digital signals are managed. Values for Q are read into all three cores, and the median value is selected. This median value is then used in critical calculations for turbine operation.