World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENCF1AEA - EPROM Set is available in stock which ships the same day.

DS200DENCF1AEA - EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENCF1AEA - EPROM Set, contact us and we will get back to you within 24 hours.

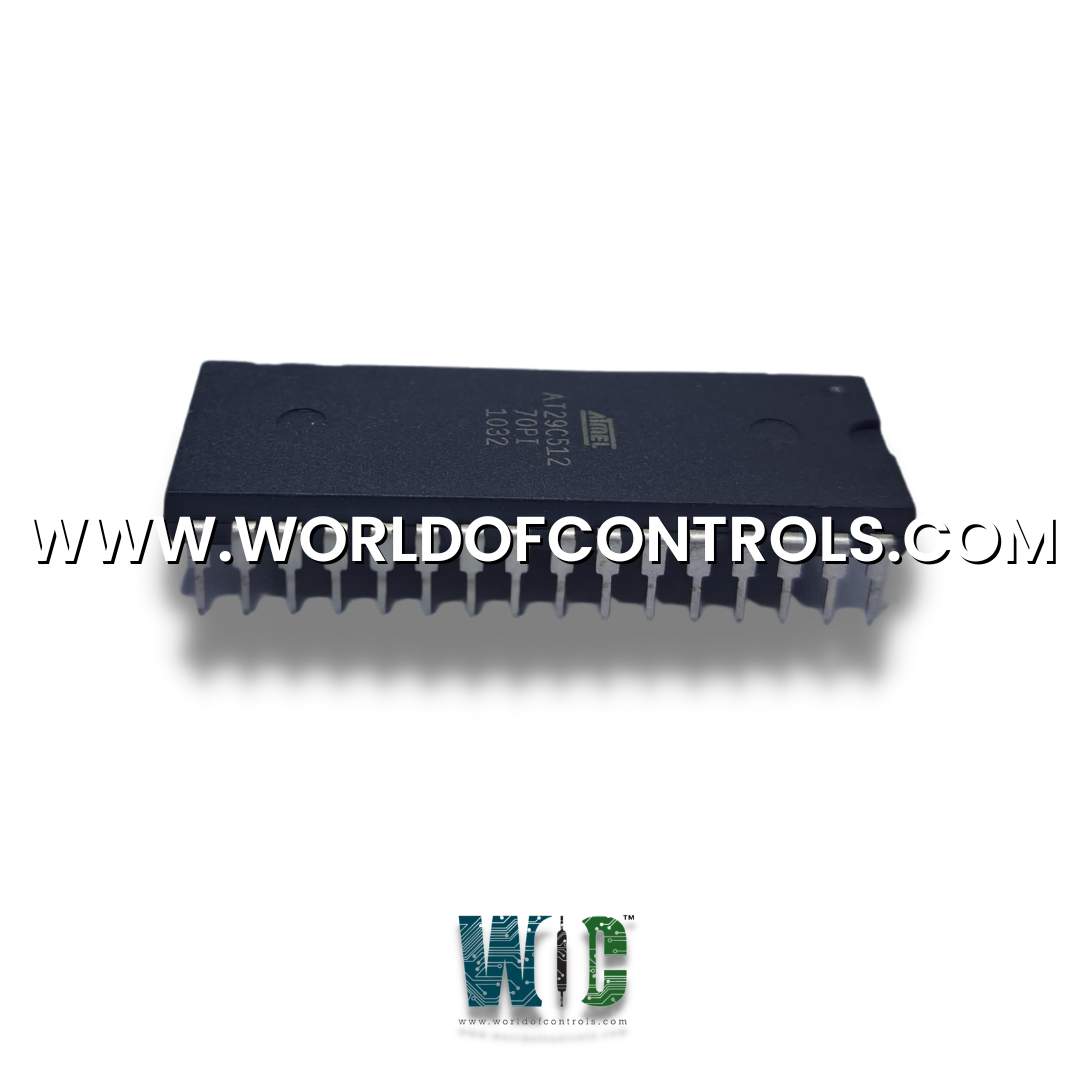

Part Number: DS200DENCF1AEA

Manufacturer: General Electric

Series: Mark V

Product type: EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENCF1AEA is an EPROM Set designed and developed by GE. It is a part of Mark V control system. The Mark V Control System takes charge of orchestrating the auxiliary systems, enabling fully automated startup, shutdown, and cooldown processes. Additionally, it encompasses critical features for safeguarding the turbine against unfavorable operational scenarios and promptly announcing abnormal conditions as part of its fundamental functionality.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENCF1AEA?

It is a EPROM Set designed and developed by GE

What is the Backup Operator Interface Panel, often referred to as BOI?

The BOI is an integral component within the Mark V System, serving as a secondary means of monitoring and controlling turbine functions. It plays a crucial role in ensuring redundancy and reliability within the control system.

How does the BOI establish communication with the Mark V System's control processors?

The BOI is equipped with its dedicated communication link, enabling a direct connection to the three control processors - R, S, and T. This direct link ensures swift and dependable data exchange, allowing real-time monitoring and control capabilities.

What are the primary physical features of the BOI's interface, and where is it typically located?

The BOI features an interface comprising an LCD panel and a keypad, making it user-friendly and intuitive for both operators and maintenance personnel. Typically, this device is securely mounted on or in close proximity to the main control panel, ensuring easy access and visibility.