World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENCF1ACF - Mark V Software PROM Set is available in stock which ships the same day.

DS200DENCF1ACF - Mark V Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENCF1ACF - Mark V Software PROM Set, contact us and we will get back to you within 24 hours.

Part Number: DS200DENCF1ACF

Manufacturer: General Electric

Series: Mark V

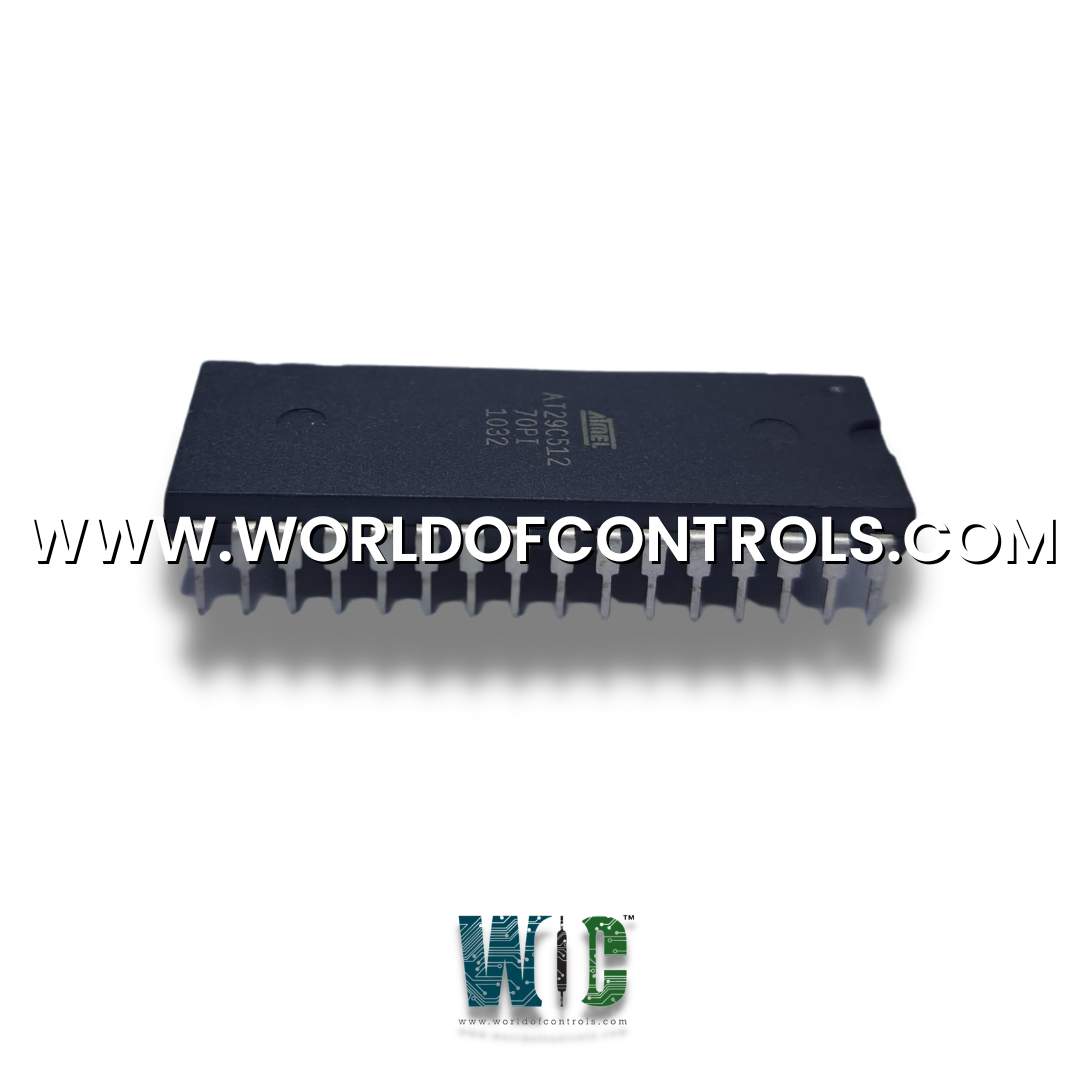

Product type: Mark V Software PROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENCF1ACF is a Mark V Software PROM Set designed and developed by GE. It is a part of�Mark V control system.�The Mark V Control System is engineered to meet all the control demands of gas turbines. These encompass the regulation of liquid, gas, or a combination of both fuels in alignment with speed requirements, precise load control during partial load scenarios, temperature control in high-capacity situations, and during startup phases. Furthermore, it manages inlet guide vanes and the injection of water or steam to comply with emissions and operational prerequisites.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENCF1ACF?

It is a Mark V Software PROM Set designed and developed by GE

What makes the Mark V Control System stand out in the field of turbine control?

The Mark V System is a cutting-edge, microprocessor-based control system specifically engineered for the precise regulation of turbines. It represents the latest advancement in this technology.

What types of turbines can the control system work with?

The Mark V is incredibly versatile and can be used with medium and large steam turbines, heavy-duty gas turbines (whether single or two shaft configurations), and aircraft derivative gas turbines.

How does the Mark V ensure control and protection for turbine units?

It�is seamlessly integrated with an array of sensors and devices positioned on the unit and its auxiliary components. This integration allows for redundancy in feedback, control, and safeguarding of critical functions. In case of a component failure, the operation remains unaffected, ensuring reliability.

Can you explain the triple modular redundant (TMR) design employed by the System?

In its most common configuration, the Mark V utilizes a TMR design with three redundant control processors. This design ensures that the unit can maintain safe operation, control, and protection even if one control processor or control processor component experiences a malfunction. It's important to note that the TMR design allows the shutdown and repair of a single control processor without needing to shut down the entire turbine, minimizing downtime.