SPECIFICATIONS

Part Number: DS200ADCIH1A

Manufacturer: General Electric

Series: EX2000

Product Function: Genius Adapter Card

Power Requirements: +5 V dc, 6 A

Number of relay channels: 12

Trip Solenoid Rating: 125 V dc

Power supply voltage: 28 V dc

Voltage Range: 18 - 32 VDC

Mounting Option: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to +65 degrees Celsius

Size: 15.9 cm high x 17.8 cm width

Product Type: PCB

Repair: 3-7 Day

Availability: In Stock

Manual: GEH-5979

Country of Manufacturer: United States (USA)

Functional Description

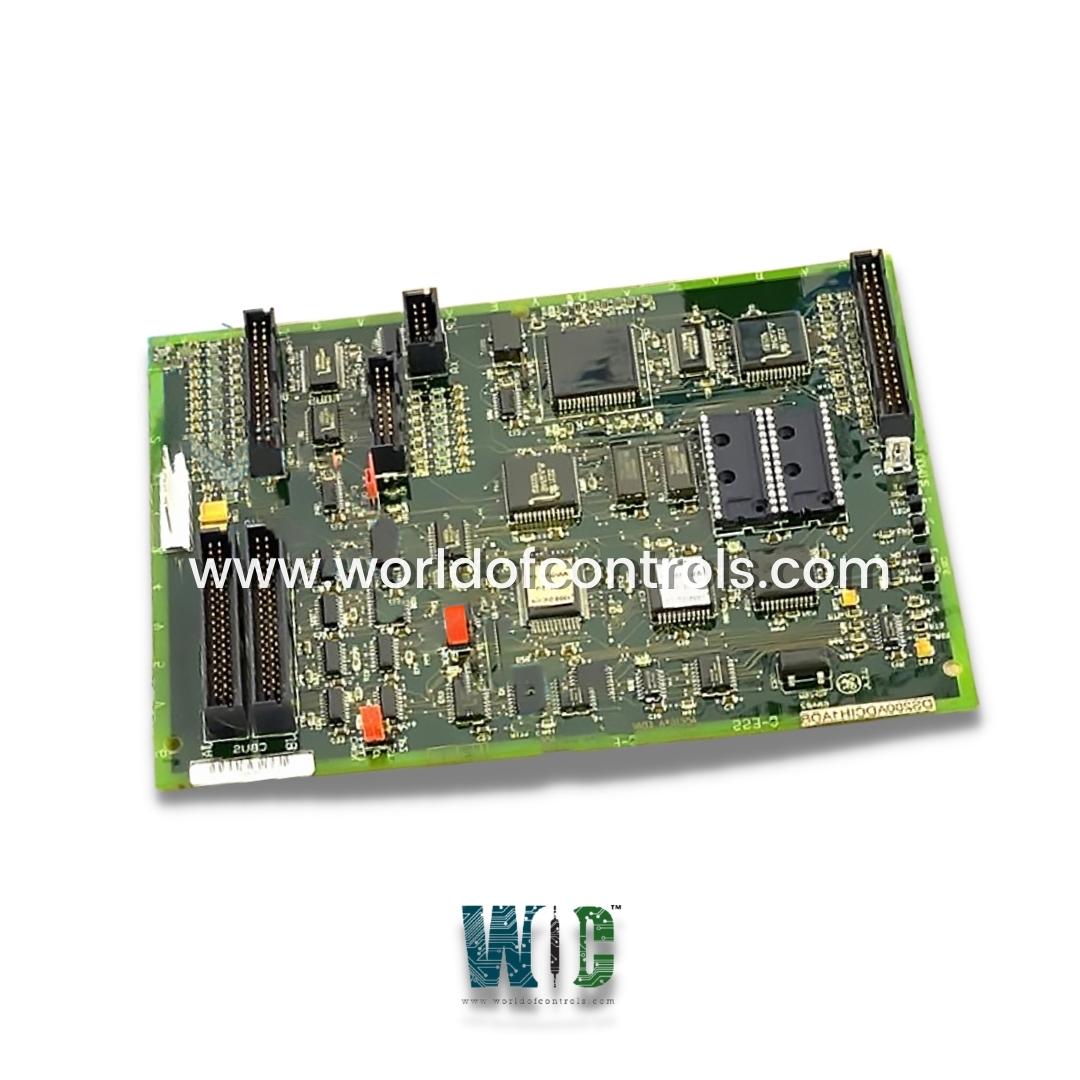

DS200ADCIH1A is a genius adapter card developed by GE. It is a part of EX2000 Series used in GE Excitation Turbine Control Systems. The adapter card acts as an interface between the turbine control system and the computer or device, allowing data to be transmitted between the two systems. The card typically includes various inputs and outputs that can be used to monitor and control the turbine, such as temperature sensors, pressure sensors, and valve controls.WOC keeps a large stock of GE parts on hand and can ship them to you within hours of receiving your order. We provide a number of shipping options to accommodate your budget and time constraints. In addition, we provide repair services and bulk purchases of surplus inventory.

The PROM modules on the Board are used to store the configuration files that govern how the drive operates. The PROM modules store a default configuration when you receive the original board from the factory. You can, however, download an editing tool that allows you to tailor the configuration to the needs of the site. The simple user interface allows you to locate and edit the parameters that need to be updated. A serial cable is connected between the drive's serial port and the laptop's serial port. You can download the configuration to the laptop from the drive's control panel. When the updates are finished, upload the configuration file to the PROM modules.

DS200ADCIH1A Features

- There are four jumpers on the GE Genius Adapter Board, one 20-pin connector, and three 40-pin connectors. It also contains two programmable memory (PROM) modules. The ADCI's 40-pin and 20-pin connectors connect to ribbon cables that carry control signals. The board receives the control signals for processing, and some of the control signals are transmitted to other boards and components in the drive.

- The ribbon cable must be handled carefully to avoid damage. Due to the construction of the ribbon cables, any stress applied to the cable may cause the wires to separate from the connector.

- When removing the cable from the board, hold it by the connector only and gently pull it away from the connector. While pulling the cable from the board, use your free hand to keep the board steady.

- Because the board has multiple connectors, it may be useful to jot down the connector identifier to which the connector is connected. Wrap the connector information around the cable with a small amount of tape. Replugging the cables becomes much easier and faster in this manner. It also reduces the possibility of plugging a cable into the incorrect connector.

- Keep in mind that you can only disconnect or reconnect cables when the drive's power is turned off. Take precautions to protect all components from static electricity.

Programmer Module

- A Programmer module with a 16-character digital display and an alphanumeric keypad is included with the EX2000. When the toolbox is not available, it serves as an operator interface for software adjustments and diagnostic testing.

- To keep the configuration tools up to date with the exciter's software configuration, permanent changes made using the Programmer module must also be made in the configuration tools.

System Operation and Maintenance

- A VGA color graphics monitor, keyboard, and printer comprise the operator interface. Normal operation displays revolve around the unit control display. It displays the status of major selections and displays key turbine parameters in a table with variable name, value, and engineering units. This screen displays a list of the last three unacknowledged alarms.

- The operator interface also includes a user-entered list of variables, known as a user defined display, in which the operator can enter any turbine-generator variable and it will be added to the variable list. To avoid accidental operation, commands that change the state of the turbine require an arm activate sequence.

- Setpoint incrementing commands, on the other hand, are processed immediately and do not require an arm-activate sequence. Alarm management screens display all alarms in the order of their time tags. The most recent alarm is added to the display list's top.

- The line indicates whether or not the alarm has been acknowledged and whether or not the alarm is still active. The alarm can be reset once the alarm condition has cleared. If reset is chosen but the alarm has not been cleared, the alarm remains and the original time tag is retained.

Software Features

System Software Overview

- The exciter employs microprocessor-based software with programmable parameters. Once controlled by adjustable hardware and software combinations, these parameters perform a variety of functions.

- The parameters are altered in order to tailor the exciter to the specific hardware and application. They also allow field and maintenance personnel to optimize the exciter's performance. These software changes are made using the Control System Toolbox (toolbox) and the EX2000 Programmer.

Software Design

- Traditional analog controls are emulated by the exciter application software. The software is built on an open architecture system that makes use of a library of pre-existing software blocks. Individually, the blocks perform specific functions such as logical AND gates, proportional integral (P.I.) regulators, function generators, and signal level detectors. These blocks are connected in a pattern to create complex control systems.

- By setting software jumpers in EEPROM, for example, a control function such as the under-excitation limit (UEL) can be included as an ac regulator input. By pointing the block inputs to RAM locations where the inputs reside, the relevant blockware is enabled (the UEL requires megawatts, kilovolts and megavars).The UEL output is then connected to an ac regulator summing junction input. The software blocks are implemented sequentially by the block interpreter in the order and at the rate specified in the toolbox. The toolbox can be used to interrogate the blockware while it is running.

- In operation, the dynamically changing I/O of each block can be seen. This method is similar to using a voltmeter to trace an analog signal.

WOC is happy to assist you with any of your automation requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200ADCIH1A?

It is a genius adapter card developed by GE

What do the 40-pin and 20-pin connectors perform?

The 40-pin and 20-pin connectors connect to ribbon cables that carry control signals. They transmit the control signals to the adapter board for processing.

What is the function of the PROM modules on the adapter board?

The PROM modules are programmable memory modules that store information for the drive's control system.

How should the ribbon cable be handled?

The ribbon cable must be handled carefully to avoid damage. Due to the construction of the ribbon cable, any stress applied to it may cause the wires to separate from the connector.

What components are on the GE Genius Adapter Board?

The GE Genius Adapter Board contains four jumpers, one 20-pin connector, three 40-pin connectors, and two programmable memory (PROM) modules.

What is the default configuration of the PROM modules?

The PROM modules store a default configuration when you receive the original board from the factory.