World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210MVRFH1A - Interface Board is available in stock which ships the same day.

IS210MVRFH1A - Interface Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210MVRFH1A - Interface Board, contact us and we will get back to you within 24 hours.

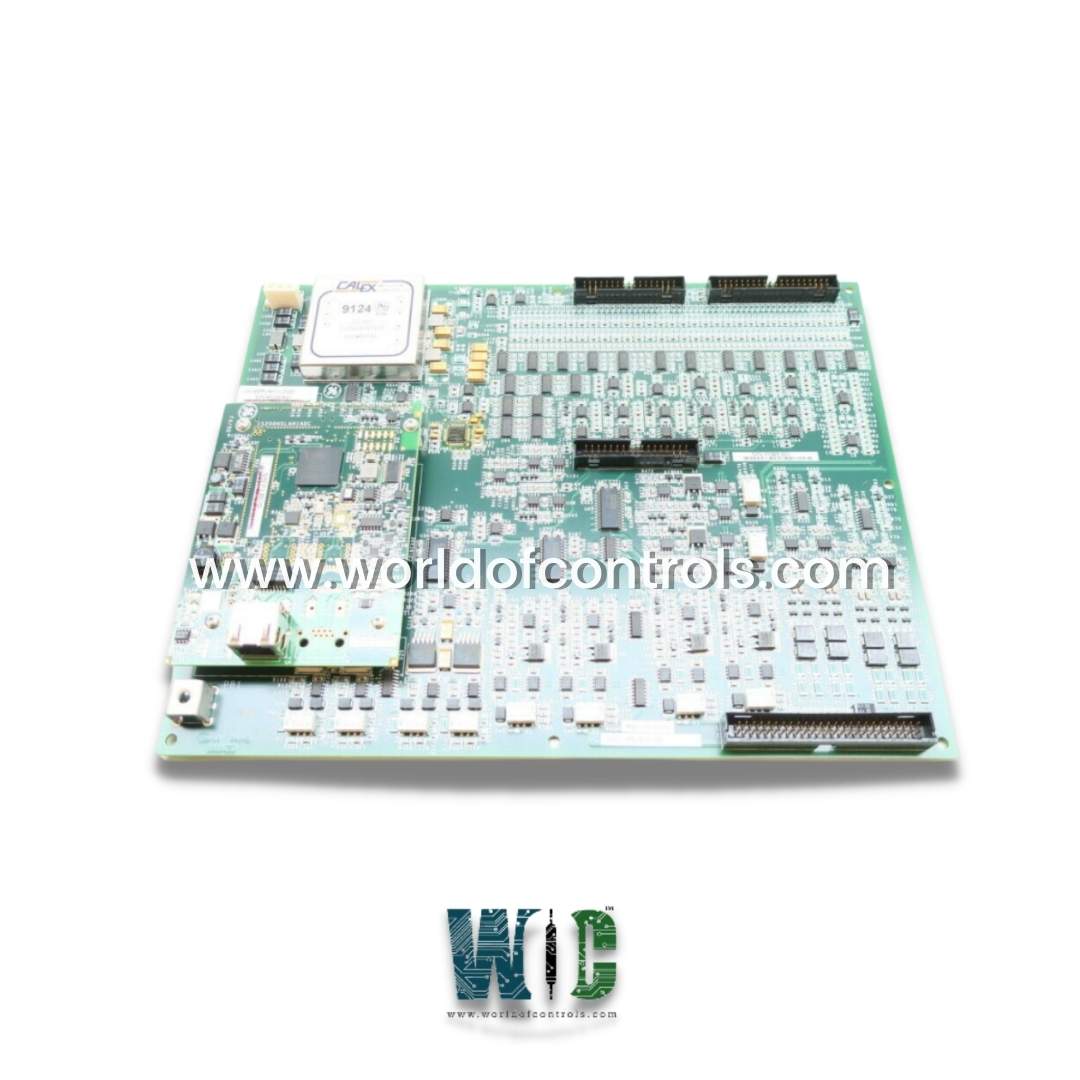

Part No.: IS210MVRFH1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Board Type: 6U high VME board, 0.787 inch wide

Processor: TMS320C32

Temperature Operating: -30 to 65oC

Product Type: Interface Board

Availability: In Stock

Series: Mark VIe

IS210MVRFH1A is an interface board developed by GE. It is a part of the Mark VIe control system. The Mark VIe control system was meticulously engineered to fulfill a diverse spectrum of control and protection tasks across various applications, ranging from steam and gas turbines to power generation balance of plant (BoP) equipment. Its architecture offers enhanced redundancy options, improved maintainability, and expanded capabilities for positioning I/O modules closer to the controlled equipment.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS210MVRFH1A?

It is an interface board developed by GE under the Mark VIe series.

How is MTBF used in system maintenance?

MTBF data assists equipment owners in scheduling maintenance activities proactively. By understanding the expected time between failures for components, maintenance can be performed before failures occur, reducing the risk of unplanned downtime.

How does MTBF help in identifying system weaknesses?

The analysis helps identify components with lower reliability, highlighting potential weak links in the system. System engineers can then focus on improving the reliability of these components or implementing redundancy measures to enhance overall system robustness.

What role does MTBF play in redundancy design?

Informs decisions regarding redundancy design. By understanding component failure rates, engineers can implement redundant systems or backup solutions to ensure continuous operation even in the event of component failures.