World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

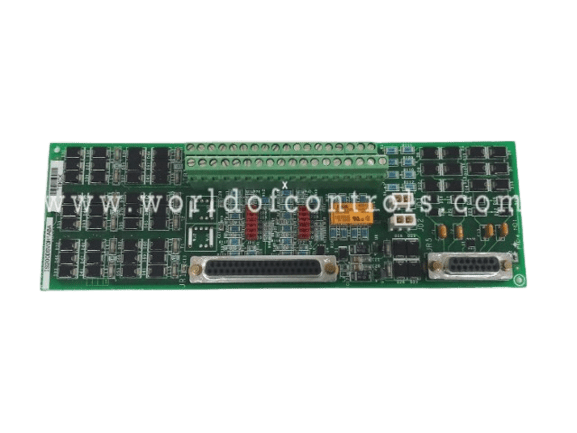

IS210DSVOH1B - Simplex Servo Input/Output Terminal Board is available in stock which ships the same day.

IS210DSVOH1B - Simplex Servo Input/Output Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210DSVOH1B - Simplex Servo Input/Output Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS210DSVOH1B

Manufacturer: General Electric

Series: Mark VI

Number of Inputs: 6

Number of Outputs: 2

Product Type: Simplex Servo Input/Output Terminal Board

Secondary Ethernet Interface: 10BaseT/100BaseTX

Pulse Rate Input: 2 Hz

Voltage Range: 14 to 32 V dc

Maximum Lead Resistance: 15 Ω

Operating temperature: 0 to 70° C

Technology: Surface mount

Size: 23.8 cm high x 8.6 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

Manual: GEH-6421M

FUNCTIONAL DESCRIPTION:

IS210DSVOH1B is a Simplex Servo Input/Output Terminal Board manufactured and designed by General Electric as part of the Mark VI Series used in GE Speedtronic Gas Control Systems. The Simplex Servo Input/Output (DSVO) terminal board is a compact terminal board designed for DIN-rail mounting. This board has two servo outputs, I/O for six LVDT position sensors, and two active pulse rate inputs for flow measurement. Servo coil currents ranging from 10 to 120 mA can be selected using jumpers. DSVO connects to the VSVO processor board with a 37-pin cable, which is identical to those used on the larger TSVO board. The terminal boards can be stacked vertically on the DIN rail to conserve cabinet space. Two DSVO boards can be connected to the VSVO if required. Only a simplex version of this board is available.

The on-board functions and high-frequency decoupling to ground are the same as those on the TSVO. High-density Euro-Block type terminal blocks are permanently mounted to the board with six screws for the ground connection (SCOM). Connectors JR1 and J5 connect to signals from onboard ID chips that identify the board to the VSVO for system diagnostic purposes. Two versions of the DSVO, H1B and H2B, are available. The H1B is a direct replacement for the previous H1A design. The H2B is certified by UL for Class 1 Division 2 applications.

INSTALLATION:

Mount the plastic holder on the DIN rail and slide the DSVO board into place. Connect the wires for the servo I/O directly to the terminal block. The Euro-Block type terminal block has 36 terminals (DSVOH1A) or 42 terminals (DSVOH1B, H2B) and is permanently mounted on the terminal board. Typically #18 AWG shielded twisted pair wiring is used. Six screws, 31-36 are provided for the SCOM connection, which should be as short as distance as possible.

OPERATION:

The input operations of the terminal board include receiving signals from various sensors, encoders, and external switches. Feedback from encoders allows the system to monitor motor position and speed, ensuring accurate movement. The board also processes control inputs, such as start, stop, direction, and speed commands, which determine how the servo motor operates. Additionally, safety signals, including emergency stop (E-Stop) inputs, are handled by the board to immediately halt operations in case of a fault or hazardous condition.

DIAGNOSTICS:

WOC has the largest stock of OEM Replacement Parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How many inputs and outputs does it have?

The board features six input channels for LVDT position sensors and other signal inputs. Additionally, it has two servo output channels that provide control signals for servo motors. This configuration enables precise positioning and motion control in industrial applications.

How does the board handle servo coil currents?

The servo coil current can be adjusted between 10 to 120 mA using onboard jumper settings. This flexibility allows users to fine-tune the current levels to match the requirements of specific servo motors, ensuring optimal performance and efficiency.

What type of mounting does this board use?

The board is designed for DIN-rail mounting, making installation simple and efficient. A plastic holder is first mounted on the DIN rail, and then the board is slid into place, allowing for space-saving installation and easy maintenance.