World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

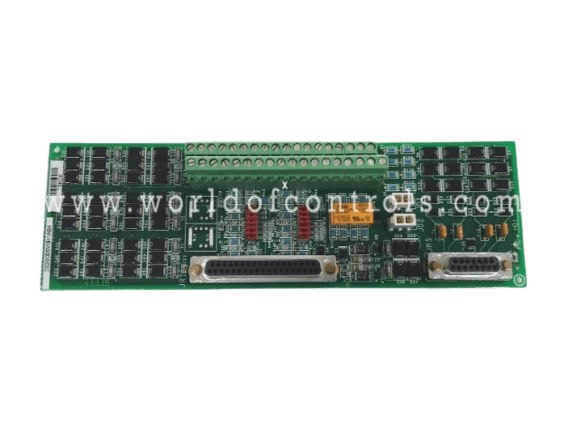

IS210DDPTH1AA - Dynamic Pressure Transducer Terminal Board is available in stock which ships the same day.

IS210DDPTH1AA - Dynamic Pressure Transducer Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210DDPTH1AA - Dynamic Pressure Transducer Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS210DDPTH1AA

Manufacturer: General Electric

Series: Mark VI

Board Type: Dynamic Pressure Transducer Terminal Board

Number of Inputs: 4

Number of Transducers: 2

Pressure wave frequency range: 1.5 Hz

Maximum lead Resistance: 15 maximum

MPU Pulse Rate Range: 2 Hz

Dimensions: 33.0 cm wide x 17.08 cm high

Mounting Type: Surface-mount

Operating Temperature Range: 30°C to +65°C

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH6721H

FUNCTIONAL DESCRIPTION:

IS210DDPTH1AA is a Dynamic Pressure Transducer Terminal Board manufactured and designed by General Electric as part of the Mark VI Series used in GE Speedtronic Turbine Control Systems. The rack-mounted VME Acoustic Monitoring Board supports the DIN-rail-mounted IS210DDPT Dynamic Pressure Transducer Terminal Board (DDPT). The DDPT configuration monitors acoustic or pressure waves in the turbine combustion chamber. The DDPT terminal board supports the simplex mode only and uses the J3 rack connector as the interface to the VAMA. The DDPT meets the environment rating for hazardous gases of Class I, Division 2, and provides suppression at all points of signal entry or exit. Each cable has a unique ID chip.

The DDPT provides two-point calibration, based on reading a reference offset and gain signal. Gas turbine combustion chambers can experience pressure oscillations that cause noise in the audible hearing range. The H1A version of the DDPT offers signal conditioning and software that allows the turbine control to monitor the pressure/acoustic waves by reading the conditioned signals from a dynamic pressure transducer. The DDPT provides two channels to read the pressure/acoustic wave signals from third-party equipment Vibro-meter or Bently-Nevada. The VAMA provides two dedicated signal conditioning paths to remove the dc component of the signal, modify the gain, and provide an eighth-order or better low-pass filter for anti-aliasing.

INSTALLATION:

To install the board, first power down the VME processor rack. Slide in the board and push the top and bottom levers in with your hands to seat its edge connectors. Then tighten the captive screws at the top and bottom of the front panel. These screws serve to hold the board firmly in place and enhance the board's front-ground integrity. The screws should not be used to seat the board. Cable connections to the DDPT terminal board are made at the J3 connector on the lower portion of the VME rack, and the J5 connector on the front of the DDPT. These are latching-type connectors to secure the cables. Power up the VME rack and check the diagnostic lights at the top of the front panel, for details refer to the section on diagnostics in this document.

OPERATION:

The VAMA provides signal conditioning for two pressure/acoustic wave inputs and an option to supply either positive 24 V dc or negative 24 V dc to power the pressure sensing equipment. The third-party vendor equipment supported are the Vibro-meter Galvanic Separation Unit Types GSI 1_ _, the Bently-Nevada 86517 with modifications 142533 or 159840 charge amplifier, or the Bently-NevadaTM dynamic pressure charge amplifier 350500. The VAMA provides signal conditioning for two pressure/acoustic wave inputs and an option to supply either positive 24 V dc or negative 24 V dc to power the pressure sensing equipment. The third-party vendor equipment supported are the Vibro-meter Galvanic Separation Unit Types GSI 1_ _, the Bently-Nevada 86517 with modifications 142533 or 159840 charge amplifier, or the Bently-NevadaTM dynamic pressure charge amplifier 350500.

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does the Dynamic Pressure Transducer Terminal Board achieve signal conditioning?

The board uses dedicated signal conditioning paths to remove DC components, modify gain, and apply advanced filtering techniques (eighth-order or better low-pass filters) for anti-aliasing.

How is power supplied to the connected pressure-sensing equipment?

The VAMA can supply either positive 24 V DC or negative 24 V DC to power the pressure-sensing equipment connected to the terminal board.

What calibration methods are supported by the Dynamic Pressure Transducer Terminal Board?

The terminal board provides two-point calibration, which involves reading a reference offset and gaining a signal for accurate measurements.