World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

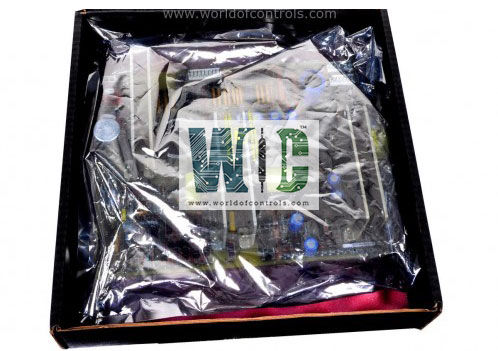

IS200VVIBH1A - Vibration Monitor Board is available in stock which ships the same day.

IS200VVIBH1A - Vibration Monitor Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200VVIBH1A - Vibration Monitor Board, contact us and we will get back to you within 24 hours.

Part No.: IS200VVIBH1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Probe signal sampling: 16-bit A/D converter

Product Type: Vibration Monitor Board

Availability: In Stock

Series: Mark VI

IS200VVIBH1A is an Vibration Monitor Board developed by GE. It is a part of the Mark VI control system. The Mark VI system incorporates Bently Nevada probes for shaft vibration monitoring, with the Vibration Monitor Board playing a central role in processing signals from these probes. This information is obtained from the TVIB terminal board, to which up to 14 probes can connect directly. Two TVIBs can then be cabled to the VVIB processor board. The VVIB digitizes the diverse vibration signals and transmits them over the VME bus to the controller.

Vibration probe inputs are typically utilized for four protective functions in turbine applications:

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

What is IS200VVIBH1A?

It is an Vibration Monitor Board developed by GE under the Mark VI series.

What types of limit checks are performed on the input signal for diagnostics?

Diagnostics include both high/low (hardware) limit checks and high/low system (software) limit checks on the input signal. The software limit check is adjustable in the field to accommodate specific operational requirements.

What conditions trigger a probe fault, alarm, or trip?

A probe fault, alarm, or trip condition is triggered if either of an X or Y probe pair exceeds its predefined limits. Additionally, the application software will inhibit a vibration trip (the AC component) if a probe fault is detected based on the DC component. This multi-layered approach ensures comprehensive monitoring and response to potential issues.

How are position inputs monitored for thrust wear protection, differential expansion, and eccentricity?

Position inputs for thrust wear protection, differential expansion, and eccentricity are monitored similarly to the vibration inputs. However, for position indication, only the DC component is utilized. This enables effective monitoring of shaft position for critical protective functions.

What type of A/D converter is used in the diagnostics system?

The diagnostics system employs a 16-bit sampling type Analog-to-Digital (A/D) converter with 14-bit resolution. The overall circuit accuracy is maintained at 1 percent of full scale, ensuring precise and reliable conversion of analog signals into digital values for further analysis.

How does the software handle vibration trips in the presence of a probe fault?

The software intelligently inhibits a vibration trip (the AC component) if a probe fault is detected based on the DC component. This feature enhances the system's ability to respond to faulty conditions and ensures that vibration trips are appropriately managed in the presence of probe faults.