SPECIFICATIONS

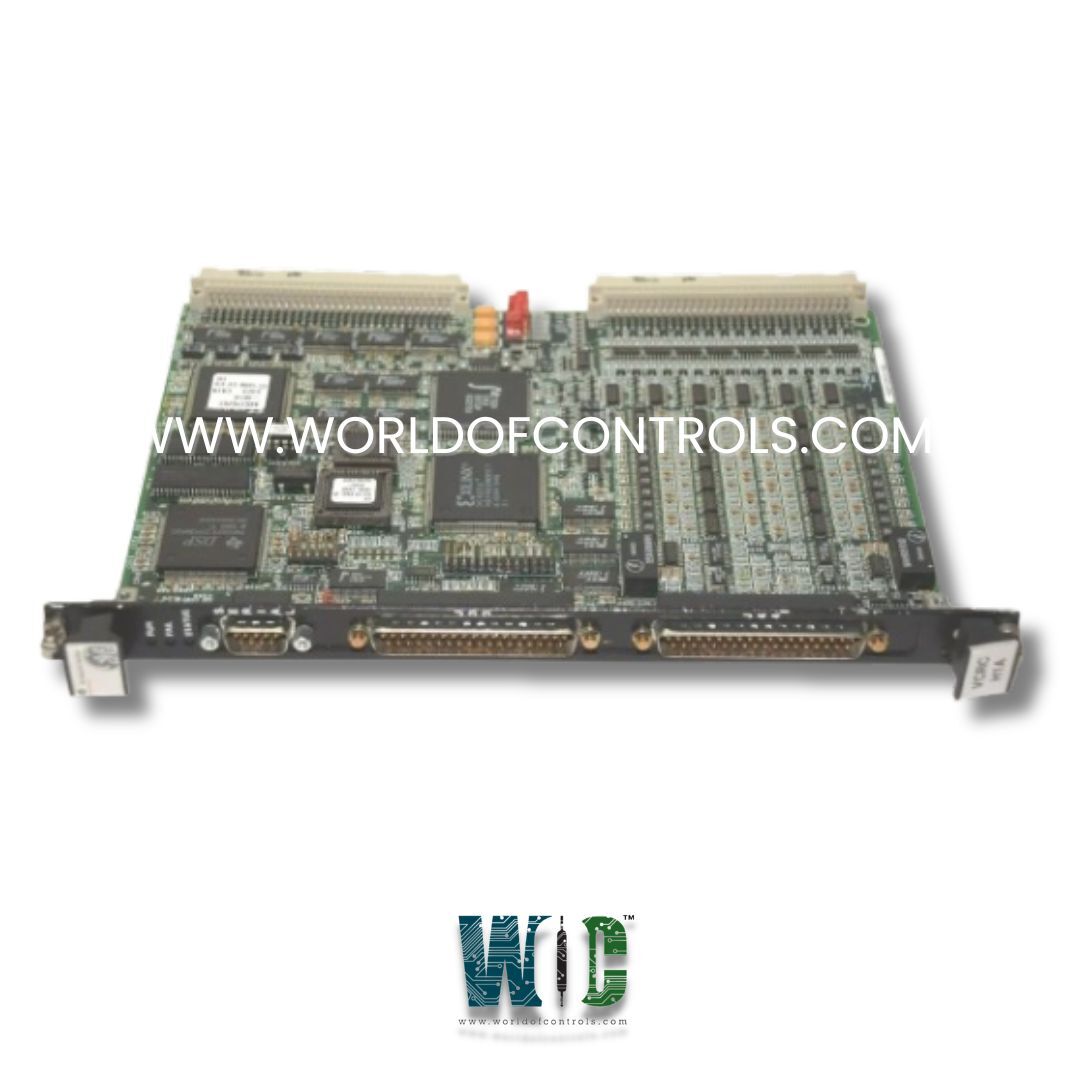

Part No.: IS200VCRCH1ABA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 26.04 cm high x 3.98 cm wide x 18.73 cm deep

Temperature: 0 to 60oC

Input isolation: Optical isolation to 1500 V on all inputs

Input filter: Hardware filter, 4 ms

Product Type: Input/Output Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200VCRCH1ABA is an Input/Output Board developed by GE. It is part of the Mark VI series. VCRC board serves as a compact and space-efficient alternative to the VCCC, offering identical functionalities while introducing some structural and connectivity differences. The board mirrors the functionalities of the VCCC, providing the same capabilities and handling of input signals within the system. It performs tasks such as signal isolation, sampling, and transfer, ensuring seamless communication between modules.

Features

- Form Factor and Design: Single-slot version of the VCCC, designed to occupy a solitary VME slot without requiring an additional daughterboard. This design minimizes the space needed within the rack while maintaining the core functionalities.

- Front Panel Connections: Contact input cables directly plug into the front of the board, providing a more accessible and front-facing connectivity option compared to the VCCC. This setup facilitates easier cable management and access during installation or maintenance procedures.

- Input Connectors: Features two front panel connectors, J33 and J44, specifically designated to accept contact inputs originating from the TBCI (Terminal Board for Control Inputs) terminal boards.

- Relay Output Connectivity: Relay outputs on the TRLY module connect to the J3 and J4 ports on the VME rack. This uniformity in relay output connectivity ensures compatibility with both VCCC and VCRC setups.

- Daughterboard: Doesn't necessitate a daughterboard for its operations, reducing its footprint within the system and optimizing slot utilization in the VME rack.

- Limitation Regarding TICI Board: Notably, the board does not support the TICI (Terminal Input Contact Input) contact voltage sensing board. Therefore, if utilizing the TICI board is a requirement, the VCCC would be the recommended choice instead of VCRC.

Contact Inputs

- The first 24 dry contact inputs are directed to a dedicated contact input terminal board, while a separate terminal board accommodates inputs 25 to 48. These terminal boards serve as the connection points for the dry contact inputs, ensuring organized and efficient wiring. Power for the contact inputs is supplied through DC power sources.

- Cables with molded plugs establish the connection between the terminal boards and the VME rack, where the VCCC processor board is located. This configuration enables seamless integration and communication between the contact inputs and the processing unit.

- For critical turbine variable monitoring, the system offers high-speed scanning and recording capabilities, operating at a rapid 1 ms rate. The Sequence of Events (SOE) recorder captures all instances of contact openings and closures with remarkable time precision, down to 1 ms. Even brief contact chatter and pulses as short as 6 ms are accurately recorded.

- The dry-contact inputs are powered by either a floating 125 V DC supply (ranging from 100 to 145 V DC) through the TBCIH1 module or a floating 24 V DC supply (with a range of 18.5 to 32 V DC) through the TBCIH2 module. To ensure reliable operation and data integrity, each input is equipped with filters designed to minimize high-frequency noise and suppress surge events near the point of signal exit. A 4 ms filter effectively mitigates noise and contact bounce, while the system maintains a robust AC voltage rejection of 60 V RMS at 50/60 Hz with 125 V DC excitation, further enhancing signal quality and accuracy.

Fault Detection Mechanisms

- Loss of Contact Input Excitation Voltage: Detection occurs when there's a loss of excitation voltage powering the contact inputs. This fault detection ensures the continuous monitoring of essential input voltage levels.

- Non-Responding Contact Input in Test Mode: Detection flags a non-responsive contact input specifically during test modes, ensuring the functionality and responsiveness of the input system.

- Loss of User Solenoid Power (Blown Fuse): Detection occurs when there's a loss of power to user solenoids, typically due to a blown fuse. This fault detection safeguards against potential disruptions in the power supply to user solenoids.

- Coil Current Discrepancy with Command: This detection mechanism identifies discrepancies between the commanded coil current and the actual current, ensuring precise control and operational consistency.

- Relay Contact Voltage Monitoring Indicating a Problem: Fault detection triggers when monitoring relay contact voltages indicates any irregularities or inconsistencies, flagging potential issues within the relay contacts.

- Unplugged Cable or Loss of Communication with I/O Board: Fail-safe mechanisms de-energize relays if communication is lost between the VCCC/VCRC board and the associated I/O board. This ensures system safety in the event of communication disruptions.

- Failed ID Chip: Detection signals a fault in the ID chip, used for board identification and information retrieval. A failed ID chip triggers a fault notification, ensuring proper board identification and compatibility.

- These fault detection mechanisms within the board play a pivotal role in maintaining system reliability and safety. By promptly identifying potential issues such as power loss, communication disruptions, or component failures, these mechanisms ensure swift resolution and prevent system malfunctions or unsafe operational states, contributing significantly to the overall stability and dependability of the system.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200VCRCH1ABA?

It is an Input/Output Board developed by GE under the Mark VI series.

What purpose do the ID devices on cable connectors serve on the terminal board?

Each cable connector on the terminal board features an ID device that holds specific identification information. These ID devices are read-only chips containing crucial data such as the terminal board's serial number, board type, revision number, and the specific JR, JS, and JT connector locations.

How are these ID devices utilized within the system?

The I/O processor interrogates these ID devices, retrieving encoded information about the terminal board. This information includes critical details such as serial numbers, board type, and connector locations.

What happens if a discrepancy is detected while reading the ID chip?

If the data read from the ID chip by the I/O processor doesn't match the expected or configured information, it signals a mismatch. This discrepancy triggers a hardware incompatibility fault within the system.