World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

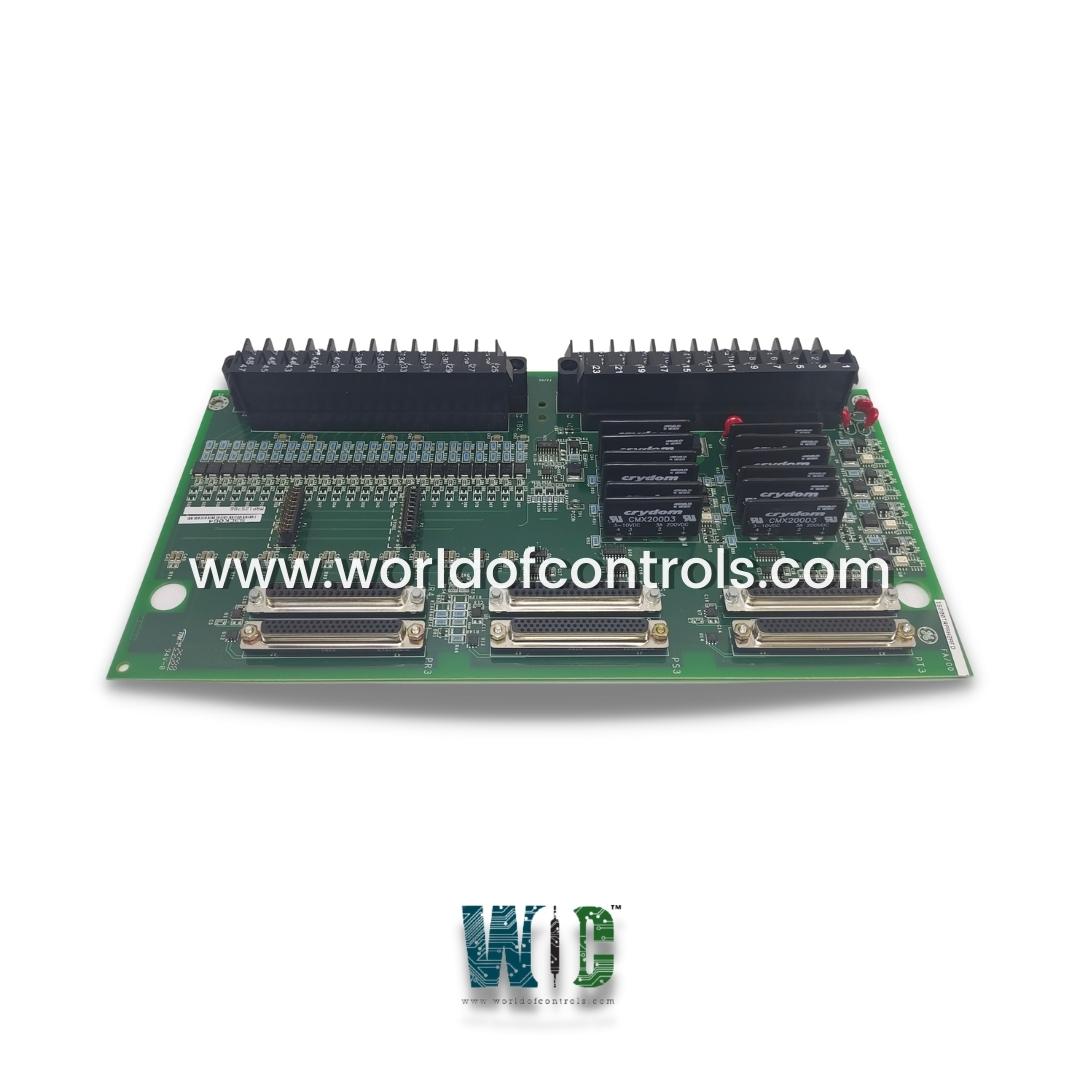

IS200TRPAH2AFD - Aeroderivative Turbine Primary Trip Terminal Board is available in stock which ships the same day.

IS200TRPAH2AFD - Aeroderivative Turbine Primary Trip Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TRPAH2AFD - Aeroderivative Turbine Primary Trip Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200TRPAH2AFD

Manufacturer: General Electric

Series: Mark VIe

Board Type: Aeroderivative Turbine Primary Trip Terminal Board

Number of Inputs: 4

Number of Outputs: 2

Input span, transmitters: 1-5 V dc

Maximum lead Resistance: 15 maximum

MPU Pulse Rate Range: 2 Hz

Dimensions: 33.0 cm wide x 17.08 cm high

Mounting Type: Surface-mount

Operating Temperature Range: 30°C to +65°C

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH6721D

FUNCTIONAL DESCRIPTION:

IS200TRPAH2AFD is an Aeroderivative Turbine Primary Trip Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distribution Turbine Control Systems. It works with PTUR / YTUR I/O packs and TTUR terminal boards as part of the Mark VIe / VIeS control system. The inputs and outputs are as follows:

INSTALLATION:

TTL pulse rate pick-ups, voltage detection, E-Stop, and the breaker relay are wired to the I/O terminal blocks TB1. Passive pulse rate pick-ups are wired to TB2. Each block is held down with two screws and has 24 terminals accepting up to #12 AWG wires. A shield termination strip attached to the chassis ground is located immediately to the left of each terminal block. The TRPA must be configured for the desired speed input connections using the following table. Jumpers JP1 and JP2 select fanning of the R section pulse rate pickups to the S and T PTURs or YTURs

DIAGNOSTICS:

WOC has the largest stock of OEM replacement parts for GE Distribution Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does the Aeroderivative Turbine Primary Trip Terminal Board detect turbine speed?

The terminal board uses pulse rate devices (both active and passive) to measure the turbine's rotational speed by sensing the movement of a toothed wheel. This data is used to detect overspeed conditions and to manage turbine trips when necessary.

What are the mounting and wiring requirements for this terminal board?

The board is typically surface-mounted and includes terminal blocks for wiring the pulse rate pickups, voltage detection circuits, and breaker relays. The terminal blocks can accept wires up to #12 AWG and are secured with screws.

How does the terminal board interact with the turbine control system?

The board interfaces with the turbine control system, such as the Mark VIeS control system, and works with I/O packs and other terminal boards (e.g., PTUR, YTUR). It ensures that trip signals, turbine speed inputs, and ESTOP conditions are communicated effectively to the control system.