SPECIFICATIONS

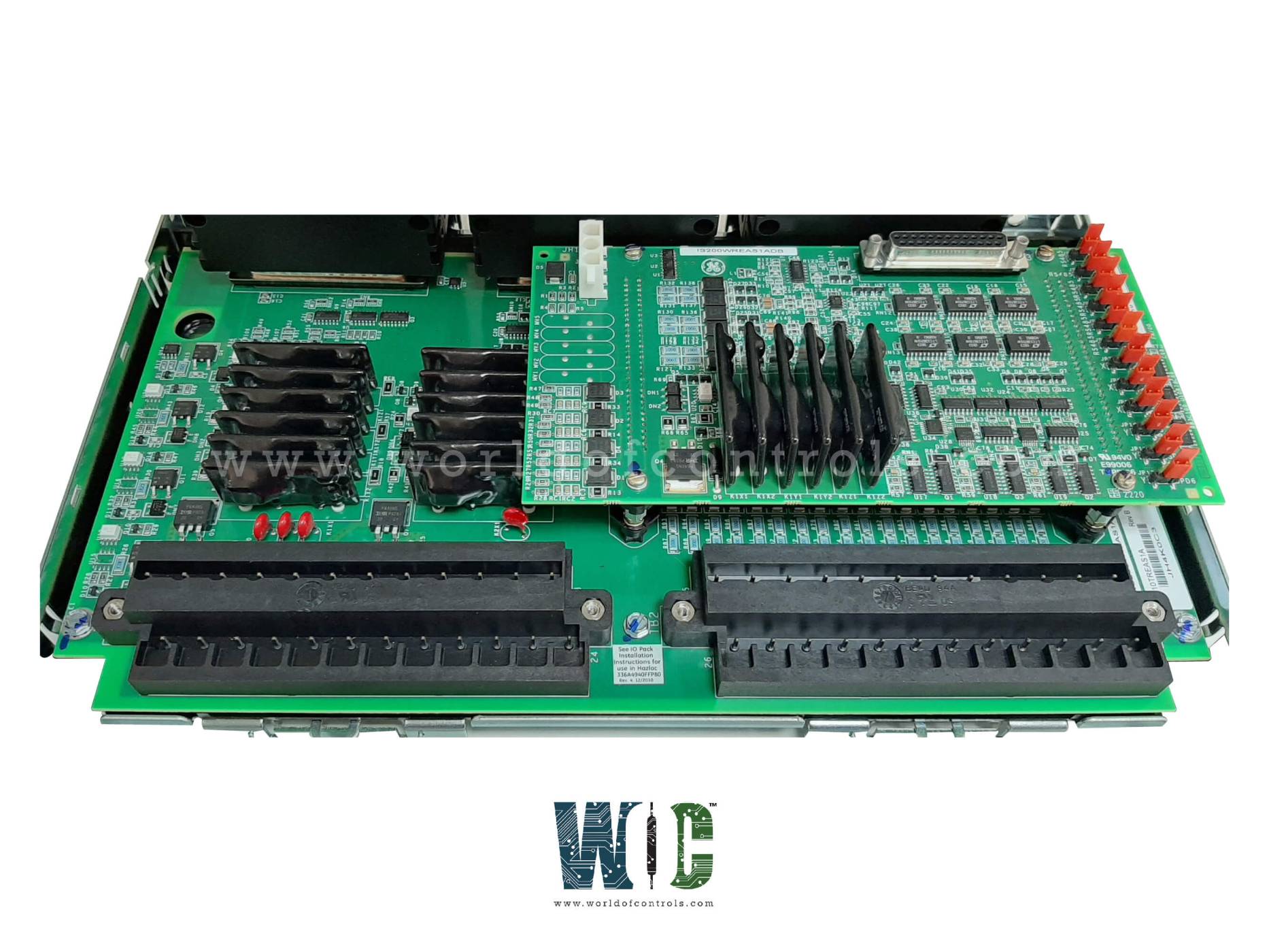

Part No.: IS200TREAS1AED

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

MPU pulse rate range: 2 Hz to 20 kHz

MPU input circuit sensitivity: 27 mV pk

Size: 33.0 cm high x 17.8 cm, wide

Technology: Surface mount

Temperature: -30 to 65oC

Product Type: Turbine Emergency Trip Terminal Board

Availability: In Stock

Series: Mark VIeS

Functional Description

IS200TREAS1AED is an Aeroderivative Turbine Emergency Trip Terminal Board developed by GE. It is a part of Mark VIeS control system. This board interfaces with PPRO and YPRO turbine I/O packs, providing a critical link between the turbine control system and the emergency trip functionalities. The board includes nine passive pulse rate devices, with three devices allocated to each of the X, Y, and Z sections. These devices are crucial for sensing the turbine speed by measuring the signals from a toothed wheel. This data is essential for precise turbine speed monitoring and control.

Features

- 24-Point Pluggable Barrier Terminal Blocks

- Jumper Blocks: Jumper blocks are provided to enable the distribution of one set of three speed inputs across all three PPRO or YPRO I/O packs. This feature ensures consistent and accurate speed input across the entire control system, enhancing the reliability of turbine speed measurements.

- Power and Trip Output Configurations

- TMR Voted Output Contacts: The board includes two TMR (Triple Modular Redundant) voted output contacts, which are crucial for initiating an emergency trip. These contacts are available in the following configurations:

- 24 V DC Outputs: Configurations H1A/S1A and H3A/S3A.

- 125 V DC Outputs: Configurations H2A/S2A and H4A/S4A.

- Voltage Detection Circuits: The board is equipped with four voltage detection circuits, which operate within a range of 24-125 V DC. These circuits continuously monitor the trip string, ensuring that any anomalies or faults in the trip circuitry are promptly detected and addressed.

- Daughterboard Connectors: The terminal board includes connectors for daughterboards, allowing for optional feature expansion. This modularity ensures that the board can be easily upgraded or customized to meet specific operational requirements or to incorporate new technologies as they become available.

Installation

- I/O Terminal Blocks (TB1): Voltage detection and breaker relay connections are managed through the I/O terminal blocks labeled TB1. These blocks play a crucial role in the system by ensuring that the necessary electrical connections are securely established. Each TB1 terminal block is designed to accommodate wires up to #12 AWG, offering flexibility in the choice of wiring. The blocks are securely fastened with two screws, which helps maintain a stable connection even under varying environmental conditions. Additionally, for effective grounding and to minimize electrical noise, a shield termination strip is provided. This strip is attached to the chassis ground and is conveniently located immediately to the left of each terminal block, enhancing the system's overall integrity and performance.

- Terminal Blocks (TB2): The TB2 terminal blocks are specifically allocated for the connection of passive pulse rate pick-ups. Like TB1, these blocks also support wires up to 12 AWG, providing ample capacity for different wiring needs. To ensure a reliable connection, each TB2 block is held in place by two screws. This secure attachment helps prevent any inadvertent disconnections that could affect system functionality. The shield termination strip, also connected to the chassis ground and located to the left of each terminal block, plays a vital role in reducing electromagnetic interference. This arrangement ensures that the pulse rate signals are transmitted with minimal noise, thereby maintaining accurate and reliable readings.

- Terminal Block Layout and Security: Both TB1 and TB2 terminal blocks feature 24 terminals each, designed to support wires up to 12 AWG. This capacity ensures that the blocks can handle a variety of wiring configurations and requirements. Each terminal block is securely fastened with two screws, which should be tightened appropriately to maintain a stable and reliable connection. Properly securing the terminal blocks is essential to prevent loose connections that could lead to system failures or inaccuracies.

- Grounding and Shielding: Effective grounding and shielding are crucial for the performance and reliability of the system. The shield termination strips connected to the chassis ground help minimize electrical noise and interference. These strips should be properly connected as specified to ensure effective grounding and shielding, thereby enhancing the overall performance and accuracy of both voltage detection and pulse rate measurements.

- Wire Preparation: Before making any connections, it is important to properly prepare the wires. This involves carefully stripping the insulation to expose the wire strands without causing damage. Using ferrules or similar connectors can help prevent fraying and ensure a secure connection. Proper wire preparation is vital for maintaining a stable and reliable connection, which is essential for the accurate functioning of the system.

- Safety Considerations: Ensuring safety during installation is paramount. Always make sure the power is turned off before starting any wiring work to prevent electrical shock or equipment damage. Double-check all connections to ensure they are secure and correctly aligned with the terminal block assignments. Adhering to relevant electrical codes and standards is essential to ensure a safe and compliant installation. By following these guidelines, you can achieve a safe, reliable, and efficient installation of the voltage detection and breaker relay system, as well as the passive pulse rate pick-ups.

E-Stop Functionality

- Overview of E-Stop in TREA: The system includes a critical E-Stop function designed to ensure safety and rapid response during emergency situations. This function is built with an optically isolated input circuit, which enhances safety by preventing electrical noise and surges from affecting the control system. The circuit is compatible with a direct current (DC) input range of 24 V to 125 V nominal, allowing for flexibility in integration with various systems.

- Circuit Operation and Response Time: When the E-Stop circuit is energized, it enables coil drive power in the X, Y, and Z relay circuits through independent hardware paths. This design ensures that the power supply to the critical relay circuits is reliably managed and controlled. The E-Stop circuit boasts an impressive response time of less than five milliseconds, ensuring that emergency actions are initiated almost instantaneously. Coupled with the trip relays' response time of less than one millisecond, the overall E-Stop response is extremely fast, crucial for safety-critical applications where every millisecond counts.

- Monitoring and Control via Firmware: The E-Stop functionality is monitored by the PPRO or YPRO firmware, which continuously checks the status of the E-Stop circuit. However, the actual action to remove trip relay coil power is executed through a hardware path in the I/O pack. This hardware-based action ensures that the E-Stop function operates independently of the software, providing an additional layer of reliability and safety.

- Configurability of E-Stop: It is possible to configure the PPRO or YPRO firmware to turn off the E-Stop function if necessary. This configurability allows for flexibility in system operation and can be tailored to specific operational requirements or maintenance procedures. However, turning off the E-Stop function should be done with caution and only when absolutely necessary, as it disables a critical safety feature designed to protect both personnel and equipment.

The WOC team is always available to help you with your Mark VIeS requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TREAS1AED?

It is an aeroderivative turbine emergency trip terminal board developed by GE under the Mark VIeS series.

How does the system use the ID device to check for compatibility?

The I/O pack, through the PPRO or YPRO firmware, interrogates the ID device on the terminal board connector. During this interrogation, the system reads the stored information and checks it against expected values. If there is a mismatch between the read data and the expected data, the system identifies a hardware incompatibility fault.

What happens if a mismatch is detected during the ID device interrogation?

If a mismatch is detected, indicating that the terminal board's ID device data does not match the expected configuration, the system generates a hardware incompatibility fault. This fault alerts the user that there is a potential issue with the terminal board installation, such as an incorrect board type or an improper plug location.

Can the ID device information be modified or updated?

No, the ID device is a read-only chip. This means that its information is permanently programmed and cannot be altered. The read-only nature of the chip ensures the integrity and consistency of the identification data.