SPECIFICATIONS

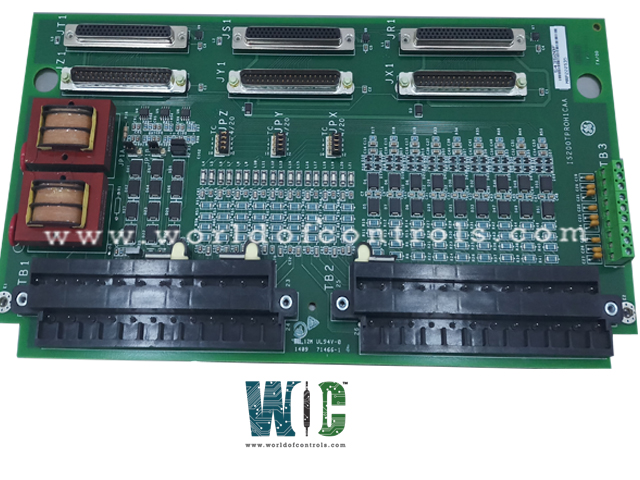

Part No.: IS200TPROH1CAA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature: -30 to +65 oC

Number of channels: 24

Thermocouple types: E, J, K, S, T

Size: 17.8 cm Wide x 33.02 cm High

Product Type: Turbine Protection Board

Availability: In Stock

Series: Mark VIe

Functional Description

IS200TPROH1CAA is a Turbine Protection Board developed by GE. It is a part of the Mark VIe control system. The TPRO system and VPRO system form an integral part of the turbine control architecture, serving as critical components in ensuring operational safety. This section outlines their roles and responsibilities within the system. It operates independently to provide essential signals for emergency overspeed and synchronization protection.

Features

- Overview of VPRO System: VPRO, comprising triple redundant boards, serves as the primary control mechanism for the emergency trip function. It coordinates the operation of trip solenoids through TREx terminals, ensuring swift response in critical situations. This subsection introduces the functionalities and configuration of the VPRO system.

- Configuration of Protection System: The protection system, consisting of triple redundant boards, operates autonomously in a separate module from the turbine control system. This subsection describes the arrangement and interconnections of the boards with the trip solenoids through TREx terminals, emphasizing redundancy and reliability.

- Role of TREx Terminals: TREx terminals, including TREG, TREL, and TRES, facilitate the control of trip solenoids within the protection system. This subsection elucidates the functions and connections of TREx terminals, highlighting their role in ensuring the safety and integrity of turbine operations.

- Emergency Trip Functionality of VPRO: It assumes the critical role of providing emergency trip functionality, ensuring rapid response in emergency situations. This subsection details the operation of VPRO in coordinating trip solenoids and implementing emergency overspeed protection and stop functions.

- Control of Trip Solenoids: Up to three trip solenoids can be connected between TREx and TRPx terminals. This subsection explains the configuration and operation of trip solenoids, emphasizing the roles of TREx and TRPx terminals in providing the necessary voltage for their operation.

- Voting Mechanism and Relay Control: VPRO controls the operation of trip solenoids through a sophisticated voting mechanism, utilizing 12 relays on the TREG board. This subsection describes the voting process and relay control, ensuring redundancy and reliability in emergency trip functions.

- Expansion Possibilities: The system allows for expansion with the integration of a second TREG board, which can be driven from VPRO through J4. This subsection explores the potential for system expansion and the integration of additional components to enhance functionality and redundancy.

Installation

- Wiring of Generator and Bus Potential Transformers, Analog Inputs, and Thermocouples: Begin by wiring the generator and bus potential transformers, analog inputs, and thermocouples to the first terminal block on the TPRO board. This step is critical for integrating essential sensors and inputs into the system, enabling accurate monitoring and control of generator and bus parameters.

- Connection of Magnetic Speed Pickups: Next, connect the magnetic speed pickups to the second terminal block on the TPRO board. These pickups play a crucial role in measuring the speed of rotating machinery, providing vital feedback for monitoring and control purposes.

- Configuration of Analog Inputs: Adjust jumpers JP1A and JP1B to configure the analog inputs according to system requirements. These jumpers allow for selecting either a 4-20 mA or voltage input on the first of the three analog inputs, providing flexibility in sensor integration and signal processing.

- Verification and Testing: Once the wiring and configuration are complete, perform thorough verification and testing of the TPRO system. Check for proper connections, signal integrity, and functionality of sensors and inputs. This step ensures that the system operates as intended and meets performance requirements.

- Integration with Control System: Integrate the TPRO system with the overall control architecture, ensuring seamless communication and interoperability with other system components. This may involve connecting to control panels, data acquisition systems, or SCADA.

- Commissioning and Calibration: Commission the TPRO system by calibrating sensors, setting operating parameters, and configuring alarm thresholds. Conduct rigorous testing under various operating conditions to validate system performance and reliability.

Operation

- Supply of Speed Signals: Serves the critical function of supplying speed signals to the VPRO system for emergency overspeed (EOS) protection of the turbine. These signals are pivotal for detecting and responding to potentially hazardous overspeed conditions, ensuring the safety of turbine operations.

- Provision of Generator Signals: In addition to speed signals, it provides generator signals for backup synchronization check protection. These signals enable the detection of synchronization faults, ensuring that the turbine remains synchronized with the grid or other power sources for stable and efficient operation.

- Handling Analog Inputs: TPRO is equipped with three analog current inputs, which serve various monitoring and protection purposes. These inputs are utilized for tasks such as monitoring exhaust over-temperature on gas turbines, providing crucial data for early detection and prevention of overheating issues.

- Management of Thermocouple Inputs: The system also accommodates nine thermocouple inputs, primarily dedicated to exhaust over-temperature protection on gas turbines. These inputs enable precise monitoring of temperature levels, allowing for prompt intervention in case of temperature anomalies to prevent potential damage to the turbine.

- Power Supply Arrangements: VPRO supplies 28 V DC power to TPRO to energize the three analog input transmitters. This ensures continuous operation of the analog input subsystem, enabling accurate and reliable monitoring of critical parameters.

- Collaboration with VPRO: TPRO and VPRO work in tandem to ensure comprehensive protection and control of the turbine system. While TPRO supplies crucial signals and inputs, VPRO provides essential power and coordination functions, ensuring seamless integration and operation of the protection system.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TPROH1CAA?

It is a turbine protection board developed by GE under the Mark VIe series.

What are the terminal board connectors in TPRO equipped with?

Terminal board connectors are equipped with their own ID device.

What is the purpose of the ID device in terminal board connectors?

The ID device serves to uniquely identify each terminal board connector within the TPRO system.

How is the information from the ID device utilized by the system?

The information from the ID device is interrogated by the I/O board, allowing the system to identify and verify each terminal board connector.

What happens if a mismatch is detected during interrogation?

If a mismatch is encountered between the information read by VPRO and the expected parameters, a hardware incompatibility fault is generated.