SPECIFICATIONS

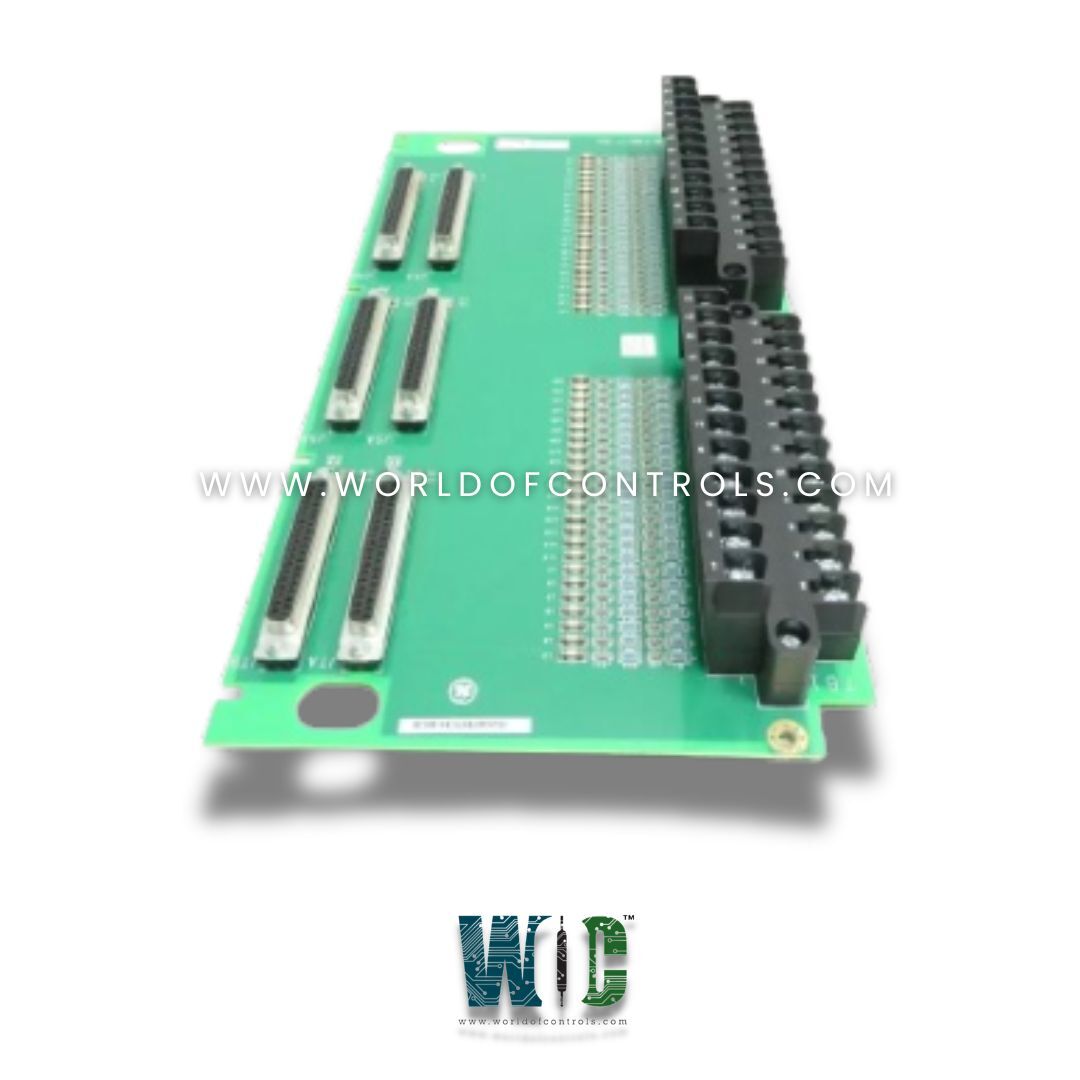

Part No.: IS200TBTCH1BCB

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature: -30 to +65 oC

Number of channels: 24

Thermocouple types: E, J, K, S, T

Cold junction temperature accuracy: 1.1oC (2 oF)

Product Type: Thermocouple Input Terminal Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200TBTCH1BCB is a Thermocouple Input Terminal Board developed by GE. It is a part of the Mark VI control system. The Thermocouple Input (TBTC) terminal board serves as a critical interface for thermocouple inputs within the system. Within Mark VI systems, the TBTC work with the VTCC processor to support both simplex and TMR applications.

Features

- Thermocouple Compatibility: Offers broad compatibility with various thermocouple types. It supports up to 24 thermocouple inputs of types E, J, K, S, or T, which are commonly used in industrial temperature measurement. Additionally, it can accommodate B, N, and R thermocouples when used in conjunction with PTCCH2 within Mark VIe systems, further expanding its application range. This compatibility ensures that the board can be integrated into various systems to handle different temperature monitoring requirements.

- Efficient Wiring System: To simplify the connection process, thermocouple inputs are wired to two barrier-type terminal blocks on the board. This design ensures secure and organized connections, reducing the risk of wiring errors and enabling efficient installation and maintenance. The barrier-type blocks also help protect the wiring from mechanical stress or interference, enhancing the reliability of the connection.

- Enhanced Communication: The board is designed to interface seamlessly with the I/O processor through DC-type connectors. These connectors ensure reliable data transmission between the thermocouple inputs and the processing unit, improving communication efficiency and accuracy within the system. The presence of six DC-type connectors allows for a high level of connectivity and versatility, making the module adaptable to different system configurations.

- Versatile Application Support: It is engineered to handle both simplex and TMR applications. In simplex setups, a single terminal board connects to the VTCC using two cables. However, in more complex TMR configurations, the board connects to three separate VTCC boards using six cables. This TMR setup offers a high level of redundancy, ensuring continued operation even in the event of a failure in one processor, which is critical for high-reliability systems.

- Robust Integration with Mark VI Systems: The board integrates smoothly with the Mark VI system, working harmoniously with the VTCC processor. This tight integration enhances the overall functionality of the control system, providing accurate and reliable thermocouple input data. The board is specifically designed to optimize performance within the existing infrastructure of the Mark VI system, ensuring seamless communication and data processing.

- TMR Configuration for High Reliability: In TMR (Triple Modular Redundant) configurations, the board is designed to interface with three VTCC boards via six cables. This setup creates a highly reliable and redundant architecture, allowing the system to continue operating even if one VTCC processor fails. This makes the TBTCH1BCB ideal for mission-critical applications where system uptime and reliability are paramount.

Installation Procedure

- Connect Thermocouple Wires: Directly connect the thermocouple wires to the two I/O terminal blocks. These blocks are affixed to the terminal board and secured in place with two screws each. Each block is equipped with 24 terminals capable of accepting wires of up to #12 AWG. Additionally, a shield terminal strip, linked to chassis ground, is situated on the left side of each terminal block to mitigate electromagnetic interference.

- Mark VI Systems: For Mark VI systems, cable the TBTC J-type connectors to the I/O processors housed within the VME rack. This involves establishing a reliable connection between the TBTC J-type connectors and the corresponding I/O processors, ensuring seamless communication between the DTTC board and the VME rack.

- Mark VIe Systems: In Mark VIe systems, the installation process differs slightly. Instead of cabling, plug the I/O packs directly into the TBTC J-type connectors. The number of cables or I/O packs required depends on the desired level of redundancy for the system. This step ensures that the DTTC board is properly interfaced with the Mark VIe system, facilitating efficient data exchange and system operation.

Cold junction compensation

- Cold junction compensation is an aspect of thermocouple measurements, ensuring accurate temperature readings by accounting for temperature differentials at the junctions where the thermocouple wires connect to the measurement circuitry. In this system, the reference junction temperature is measured at two locations on each H1C terminal board, providing essential data for compensation.

- In the case of the TMR (Triple Modular Redundancy) H1B board, cold junction compensation is particularly robust, featuring six reference junctions. However, in Mark VIe systems utilizing I/O packs, only three of these reference junctions are available for use. This limitation necessitates careful consideration in system design to ensure adequate compensation for temperature differentials across the thermocouple connections.

- The accuracy of cold junction temperature measurements is crucial for precise compensation. In this system, cold junction accuracy is specified at 1.1°C, indicating the level of precision maintained in measuring these reference temperatures. This high level of accuracy is essential for minimizing errors in thermocouple temperature readings, particularly in applications where precision is paramount, such as industrial process control or scientific research.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TBTCH1BCB?

It is a thermocouple input terminal board developed by GE under the Mark VI series.

What is hardware-limit checking for thermocouples?

Each thermocouple type has preset high and low levels near the ends of its operating range. If a thermocouple reading exceeds these limits, a logic signal is triggered, and the input is no longer scanned. Exceeding these limits generates a composite diagnostic alarm.

How are terminal board connectors identified and verified?

Each connector on the terminal board has its own ID device that the I/O board interrogates. This device contains essential information such as the terminal board's serial number, type, revision number, and the location of the J connector. If there's a mismatch or inconsistency detected, a hardware incompatibility fault is generated.

What is the purpose of injecting a small current into thermocouple paths?

During operation with the I/O processor, a minimal current is injected into each thermocouple path. This current is used to detect open circuits and is intentionally polarized to produce a low temperature reading if a thermocouple becomes disconnected or open. This feature helps in identifying potential faults or failures in the thermocouple circuitry.