World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TBCIH1CAA - Contact Input Terminal Board is available in stock which ships the same day.

IS200TBCIH1CAA - Contact Input Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TBCIH1CAA - Contact Input Terminal Board, contact us and we will get back to you within 24 hours.

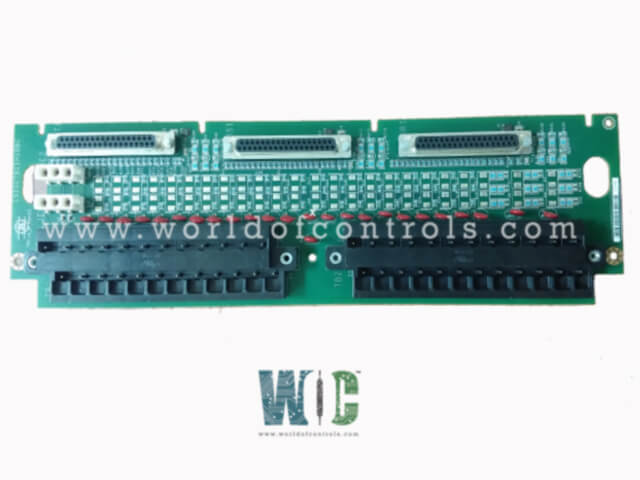

Part No.: IS200TBCIH1CAA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 33.02 cm high x 10.16 cm wide

Temperature rating: 0 to 60 oC

Current suppression: MOVs

Product Type: Contact Input Terminal Board

Availability: In Stock

Series: Mark VI

IS200TBCIH1CAA is a Contact Input Terminal Board developed by GE. It is a part of Mark VI control system. It is an interface for 24 dry contact inputs, organized across two barrier-type terminal blocks. These inputs are integrated into the system for various control and monitoring purposes. It requires a nominal 125 V dc excitation voltage, floating within a 100 to 145 V DC range. This voltage is supplied for contact excitation and operation. To ensure reliable functionality, the contact inputs are equipped with noise suppression circuitry. These circuits mitigate high-frequency noise and suppress surges, safeguarding against potential disruptions in the input signals.

To enhance signal reliability, the terminal board is equipped with noise suppression circuitry, which mitigates high-frequency noise and voltage surges. This feature ensures that input signals remain clear and free from electrical interference, improving overall system stability and performance.

For signal processing and electrical isolation, the module directs discrete input voltage signals to the I/O processor for further handling. Optical isolators are incorporated to provide group isolation, ensuring electrical separation between circuits while maintaining accurate signal transmission. This setup helps prevent issues like ground loops and voltage fluctuations, safeguarding system functionality.

The TBCI isolation circuits establish a transition threshold at 50% of the applied floating power supply voltage, ensuring precise signal recognition and state determination. To maintain operational stability, the voltage tracking mechanism prevents voltage levels from falling below 13% of the nominal rated supply voltage. If this limit is breached, all contacts are forced into an open state, preventing erroneous readings.

Designed for seamless integration with the Mark VI control system, the terminal board features barrier-type terminal blocks for structured connections. Its design optimizes system performance by minimizing electrical noise, ensuring accurate voltage thresholds, and maintaining stable excitation, making it a reliable choice for power plants, automation systems, and industrial applications.

Built to withstand harsh industrial environments, offers robust electrical insulation, high-temperature resistance, and long-term durability. Its combination of optical isolation, noise suppression, and threshold tracking significantly reduces the risk of signal loss or malfunction, ensuring efficient control and monitoring in critical applications.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

What is IS200TBCIH1CAA?

It is a contact input terminal board developed by GE under the Mark VI series.

How does TBCI protect incoming signals from noise and surge?

Filters strategically placed near the entry point of each input effectively reduce high-frequency noise and suppress surge, ensuring reliable signal integrity within the system.

How are input signals managed and isolated within the system?

The processed discrete input voltage signals travel to the I/O processor before passing through optical isolators. These isolators ensure group isolation and facilitate the transfer of processed signals to the system controller for further handling and analysis.

What role does the reference voltage play in TBCI's isolation circuits?

The reference voltage determines a transition threshold at 50 percent of the floating power supply voltage. Additionally, a clamping mechanism maintains a minimum voltage level, ensuring all contacts indicate an open state if the voltage dips below this threshold.