SPECIFICATIONS

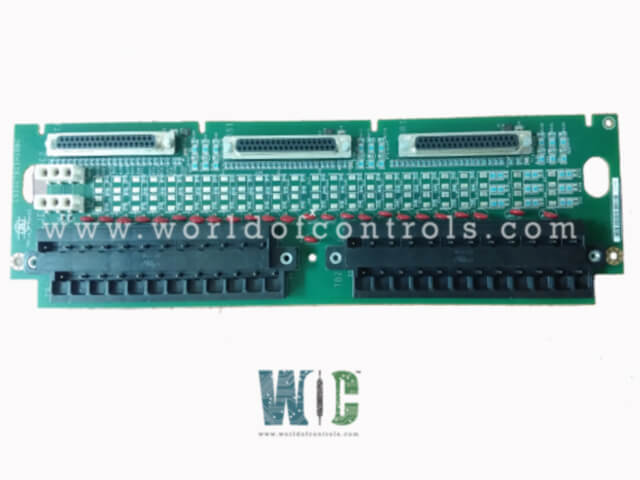

Part No.: IS200TBCIH1BAB

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Input filter: Hardware filter, 4 ms

Power consumption: 20.6 watts on the terminal board

Number of channels: 24 contact voltage input channels

Temperature rating: 0 to 60 oC

Size: 33.02 cm high x 10.16 cm wide

Temperature Operating: -30 to 65 o C

Product Type: input terminal board

Availability: In Stock

Series: Mark VI

Functional Description

IS200TBCIH1BAB is an input terminal board developed by GE. It is a part of Mark VI control system. The contact input terminal board (TBCI) is an essential component of the system, serving as the interface for 24 dry contact inputs. This document elaborates on the functionality and features of the TBCI, highlighting its role in facilitating the operation of contact inputs.

Features

- Connectivity: Designed to accommodate 24 dry contact inputs, which are connected to two barrier type terminal blocks. These terminal blocks provide a secure and organized connection interface for the contact inputs, ensuring efficient wiring and connectivity.

- Power Supply: DC power is supplied to the TBCI to enable contact excitation, essential for the proper functioning of the contact inputs. This power supply mechanism ensures continuous operation and reliability of the input signals.

- Noise Suppression Circuitry: To maintain reliable operation in diverse environments, the contact inputs are equipped with noise suppression circuitry. This circuitry is designed to suppress surge and high-frequency noise, thereby preserving the integrity of input signals and preventing interference-related issues.

- Transition Threshold: In the isolation circuits of the TBCI, the reference voltage plays a crucial role in setting a transition threshold. This threshold is carefully calibrated to 50 percent of the applied floating power supply voltage. By doing so, accurate detection of input transitions is ensured, enhancing the overall reliability and performance of the system.

- Clamping Mechanism for Stability: To enhance system stability and mitigate the risk of false readings, a clamping mechanism is employed in the tracking process. This mechanism ensures that the tracking maintains a minimum level of 13 percent of the nominal rated supply voltage. As a result, all contacts indicate an open state when the voltage dips below this threshold, effectively preventing erroneous readings caused by voltage fluctuations.

- Terminal Points Configuration: For each input, the TBCI offers a pair of terminal points, ensuring a robust and organized connection interface. One terminal point (screw) serves as the positive DC source, while the second point provides the return path (input) to the board. This setup facilitates efficient and secure wiring, ensuring reliable connectivity for each input.

- Current Loading: The current loading configuration is tailored to meet the specific requirements of the system. For the first 21 inputs on each terminal board, a current loading of 2.5 mA per point is applied. This allocation ensures optimal performance and stability for the majority of input channels. Additionally, the last three inputs on each terminal board are equipped with a higher current loading of 10 mA per point. This increased loading capacity is necessary to support the interface with remote solid-state output electronics, ensuring seamless integration and compatibility with external devices.

Contact Input Circuitry

- The contact input circuitry is meticulously designed to adhere to NEMA Class G standards for creepage and clearance. This classification signifies the circuitry's ability to withstand high levels of electrical stress and maintain safe separation distances between conductive elements, ensuring reliable and safe operation in various environmental conditions.

- By adhering to NEMA Class G standards, the TBCI ensures robust insulation and isolation properties, mitigating the risk of electrical arcing, leakage, and other potential hazards associated with contact input circuits. This meticulous design approach enhances the overall safety and reliability of the TBCI in demanding industrial applications.

Installation

- To install and wire the system, start by connecting the wires for the 24 dry contact inputs directly to the two I/O terminal blocks located on the terminal board. These terminal blocks, secured with two screws, are designed for easy maintenance as they can be unplugged when required. Each block provides 24 terminals capable of accommodating wires up to #12 AWG in size. To the left of each terminal block, a shield terminal strip connected to the chassis ground is available. This strip is used to attach shielding wires, reducing electromagnetic interference and ensuring system stability.

- The power connection requires linking the TBCI to the contact excitation voltage source using plugs JE1 and JE2. It is critical to follow the wiring configuration specified in the system documentation, ensuring the voltage and polarity align with system requirements. Proper tightening of these connections is essential to avoid operational issues. Refer to the provided schematic or system figure to confirm the accuracy of the setup.

- For cabling connections, a simplex system involves connecting the TBCI to the I/O processor via connector JR1. In TMR (Triple Modular Redundant) systems, the TBCI is connected to I/O processors using connectors JR1, JS1, and JT1. Depending on the type of Mark VI or Mark VIe system and its redundancy level, appropriate cables or I/O packs are plugged in as specified. All connections must be securely latched and verified against the system manual to ensure compatibility and operational integrity. After completing the wiring and connections, inspect all components thoroughly before powering up the system to ensure optimal functionality.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TBCIH1BAB?

It is an input terminal board developed by GE under the Mark VI series.

What is the role of the TBCI in the system?

It serves as the interface for 24 dry contact inputs, facilitating their integration into the system. This document provides insights into the functionality and features of the TBCI, emphasizing its importance in enabling the operation of contact inputs.

How are the contact inputs connected?

TBCI accommodates 24 dry contact inputs, which are connected to two barrier type terminal blocks. These terminal blocks offer a secure and organized connection interface, ensuring efficient wiring and connectivity for the contact inputs.

How is power supplied?

DC power is supplied to enable contact excitation, which is essential for the proper functioning of the contact inputs. This power supply mechanism ensures continuous operation and reliability of the input signals.

How does the TBCI address noise in input signals?

To maintain reliable operation in diverse environments, the contact inputs are equipped with noise suppression circuitry. This circuitry is specifically designed to suppress surge and high-frequency noise, preserving the integrity of input signals and preventing interference-related issues.