SPECIFICATIONS

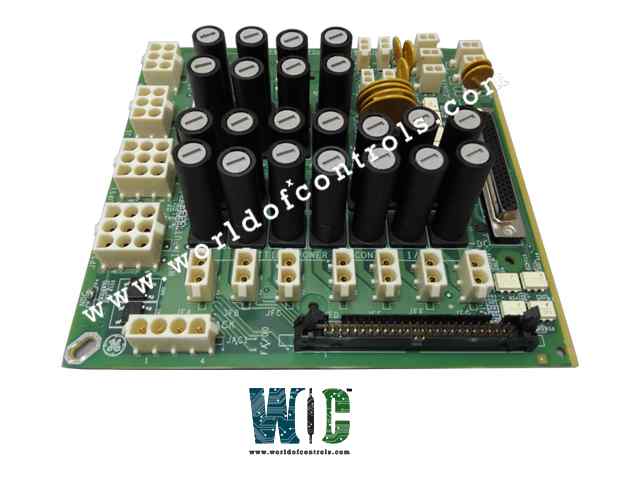

Part Number: IS200JPDGH2A

Manufacturer: General Electric

Series: Mark VIe

Ambient temperature: 30oC to 60C

Temperature: -30 to 65oC

Size: 16.51 cm High x 17.8 cm Wide

Mounting: DIN-rail

Availability: In Stock

Product type: Power Distribution Module

Country of Manufacture: United States (USA)

Functional Description

IS200JPDGH2A is a Power Distribution Module developed by GE. It is a part of the Mark VIe control system. The Power Distribution Board is a component within the control system, designed to manage and distribute both control and wetting power to other boards. Its robust design ensures efficient power management and integration with other system components.

Features

- The board distributes 28 V DC control power and 48 V / 24 V DC wetting power to various boards within the control system. This distribution ensures that all connected components receive the necessary power to function correctly.

- Equipped with sensing circuitry capable of monitoring two channels of AC distribution. This feature allows the board to provide vital feedback on the status of the AC power, ensuring stable and reliable power distribution throughout the system.

- The 28 V DC distribution section is designed to accept two separate power supply inputs. These inputs are routed through external diodes, which help prevent backflow and ensure a steady and reliable power supply. This dual-input design enhances the redundancy and reliability of the power distribution system.

- When integrated with the PPDA I/O pack, the JPDG becomes part of the Power Distribution Module (PDM) system feedback loop. This integration allows for more comprehensive monitoring and control of the power distribution, contributing to the overall stability and efficiency of the control system.

- The board supports sensing and diagnostic capabilities for two AC signals. These signals are distributed outside the board, allowing for external monitoring and diagnostics. This capability is crucial for the detection of issues and for maintaining the system's operational integrity.

Installation Procedure

- Mounting Configuration: The Power Distribution Board is base-mounted vertically on a metal bracket within a cabinet used by the Power Distribution Module (PDM). This configuration ensures stability and secure placement within the control system environment. The board is fastened using four screws, with mounting holes located at both the top and bottom of the module base. This secure attachment is crucial for maintaining the board position and ensuring reliable operation.

- Connector Placement: A 50-pin diagnostic connector, labeled P2, is mounted on the bottom of the board. This connector is essential for interfacing with other components and facilitating diagnostic feedback. The careful placement of this connector ensures easy access and connection, which is vital for effective communication and diagnostics within the system.

- Location Considerations: While the specific location of the JPDG within the control cabinet is not critical, distribution boards are typically mounted low in the cabinet. This placement strategy aids in facilitating grounding and ensuring that the board is easily accessible for maintenance and inspection. Proper grounding is essential for the safe and effective operation of the power distribution system.

- Integration with PPDA I/O Pack: The I/O pack is connected to the JPDG via connector JA1. This connection is secured using an angle bracket, and nuts are threaded onto studs permanently attached to the base of the JPDG. This secure attachment ensures that the PPDA I/O pack remains firmly in place, providing stable and reliable integration with the JPDG.

- Diagnostic Feedback: Diagnostic feedback inputs from other distribution boards are routed to the JPDG through a 50-pin ribbon cable connected to P2. This configuration allows for comprehensive monitoring and diagnostics, enabling the system to detect and address issues promptly. Proper routing and secure connection of these cables are essential for maintaining the integrity and reliability of the diagnostic feedback system.

Configuration

- Equipped with a jumper, labeled JP1, that plays a pivotal role in configuring the voltage-centering feature of the board. When jumper JP1 is in place, it activates the voltage-centering resistors. These are 12 kohm resistors that connect the positive and negative DC lines to the local earth connection. The purpose of these resistors is to balance the DC voltage, ensuring it is centered relative to the earth, which can help in reducing electrical noise and improving system stability.

- If the JP1 jumper is removed, the connection to the local earth is opened. This means that the voltage-centering resistors are disconnected, allowing the DC bus to float without a direct earth reference. This configuration might be desirable in specific scenarios where an isolated DC bus is needed or when the earth reference is provided through other means in the system.

- Inserting the JP1 jumper is recommended when a floating DC bus needs to be centered on the earth. Centering the DC bus can be important in applications where voltage stability and noise reduction are critical. This configuration helps in maintaining a consistent voltage level, reducing the potential for transient spikes and improving overall system performance.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IS200JPDGH2A?

It is a Power Distribution Module developed by GE.

When should I insert the JP1 jumper?

You should insert the JP1 jumper when you need the floating DC bus to be centered on the earth. This is typically necessary in scenarios where voltage stability and noise reduction are critical for system performance.

What are voltage-centering resistors, and why are they important?

Voltage-centering resistors are resistors that connect the positive and negative DC lines to the local earth, balancing the DC voltage around the earth reference. They are important for reducing electrical noise and enhancing the stability of the DC voltage in the system.

Are there any risks associated with removing the JP1 jumper?

Removing the JP1 jumper can result in the DC bus floating without an earth reference, which might introduce voltage instability or electrical noise if not managed properly. This configuration should only be used when an isolated DC bus is required or when alternative earth referencing is provided.