World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

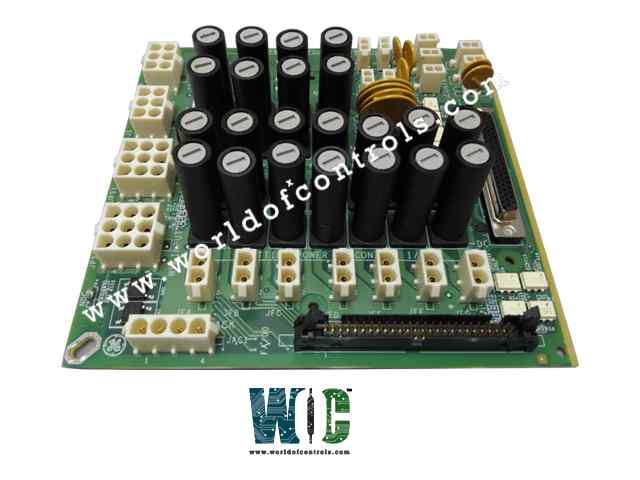

IS200JPDGH1AAB - Power Distribution I/O Module is available in stock which ships the same day.

IS200JPDGH1AAB - Power Distribution I/O Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200JPDGH1AAB - Power Distribution I/O Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200JPDGH1AAB

Manufacturer: General Electric

Series: Mark VIe

Product Type: Power Distribution I/O Module

Processor: 300 MHz Intel Celeron

Analog output current: 0-20 mA

Temperature Operating: -30 to 65 degrees C

Memory: 128 MB of flash memory

Size: 17.8 cm wide x 33.02 cm high

Operating System: QNX

Frequency: 50 or 60 Hz

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH-6725M

FUNCTIONAL DESCRIPTION:

IS200JPDGH1AAB is a Power Distribution I/O Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE-distributed turbine control systems. The diodes may be external to the power supply or built into it. The optional PPDA I/O pack mounts on the JPDG and DIN-rail base and monitors the DC core control and I/O wetting power signals on the JPDG, along with inputs for AC grid power feeding the power supplies. The JPDG can supply power to multiple JPDH boards, each JPDH fanning control power through self-resetting polymer fuses (Positive Temperature Coefficient Thermistor [PTC]) to multiple I/O packs. The JPDG can also supply I/O wetting power to multiple JPDD I/O wetting power distribution boards fanning to fanning fused I/O wetting power to multiple I/O terminal boards.

FUNCTIONS:

WOC has the largest stock of OEM Replacement Parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What are the main functions of a Power Distribution I/O Module?

The main functions of a Power Distribution I/O Module include distributing power to I/O devices, providing circuit protection, regulating voltage, monitoring power status, and ensuring reliable operation of connected devices. It may also include load balancing and grounding features to enhance system stability.

Why is circuit protection important in a Power Distribution I/O Module?

Circuit protection is vital because it safeguards the control system from electrical faults such as short circuits or overcurrent conditions. By preventing these faults from damaging sensitive components, the module ensures the safety and reliability of the entire system.

How does the Power Distribution I/O Module integrate with other control system components?

The module interfaces with various I/O devices and other control system components, distributing power and facilitating communication between the devices and the system�s central processor. This integration is key to maintaining coordinated and efficient control over the entire system.