SPECIFICATIONS

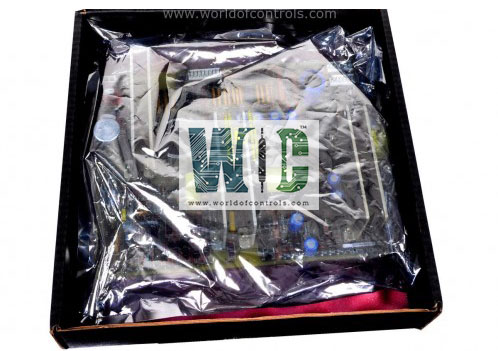

Part No.: IS200IVSHG1A

Manufacturer: General Electric

Temperature -30 to 65 oC

Product Type: Feedback Shield Board

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

IS200IVSHG1A is a Feedback Shield Board developed by GE. It is a part of Mark VIe control system. It is a part of GE's Innovation Series Medium Voltage AC Drives, which are engineered for high-performance motor control in industrial settings. These drives are commonly used to manage 2300 VAC induction motors with exceptional precision and efficiency, making them an integral component in various industries that rely on robust and reliable drive systems.

Feedback Shield Board Features

- 3-Level, IGBT-Based Pulse Width Modulation (PWM) Inverters: The drives are equipped with state-of-the-art 3-level inverters that utilize IGBT-based PWM technology. This technology delivers highly accurate motor control, ensuring smooth and efficient motor operations while minimizing energy consumption.

- Liquid-Filled Capacitors: Liquid-filled capacitors are used in the drive system to provide superior performance and reliability. These capacitors are designed to store and distribute energy efficiently, thus optimizing the energy storage and enhancing the overall system’s longevity.

- 3-Level Inverters for Cleaner Output: The 3-level inverters generate smoother output waveforms compared to traditional inverters. This helps in reducing harmonic distortion, improving the quality of power supplied to the motor, and ensuring a quieter and more stable motor operation.

- Continuous Software-Implemented Fault Tolerance (SIFT) Monitoring: The Innovation Series Medium Voltage AC Drives come with continuous Software-Implemented Fault Tolerance (SIFT) monitoring. This advanced feature ensures the continuous operation of the system by actively detecting potential faults and correcting them in real time, thereby minimizing downtime and improving reliability.

- Operator Controls with Graphical and Digital Displays: The drive system includes an intuitive control interface, mounted on the door of the drive cabinet. This interface offers both graphical and digital displays, providing operators with detailed information about the system's performance, fault status, and overall health.

- Tune-Up and Monitoring Tools: The system comes with built-in tune-up and monitoring tools that are easily accessible through an operator-friendly menu. These tools feature display and help functions, making system configuration and troubleshooting easier and more efficient.

Load Cabinet Components

- Blower Assembly: The blower assembly is responsible for maintaining optimal temperature within the cabinet by circulating air, preventing overheating of the drive components.

- AC Buswork: The AC buswork connects various components in the drive system, providing a pathway for electrical power to flow efficiently.

- Capacitor Assemblies: The capacitor assemblies are integral for energy storage, providing the necessary charge and ensuring smooth operation of the drive.

- Cable Assemblies: These include a range of cables used for power transmission and control signal routing within the system.

- Interface Module: The interface module ensures smooth communication between the control system and the drive components, acting as a central hub for data exchange.

- Phase Leg Assembly: The phase leg assembly helps manage the power distribution across different phases of the motor.

- Optional Space Heater: The space heater is used to maintain the ideal temperature conditions within the load cabinet, particularly in environments where external temperatures might cause condensation or moisture buildup.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS200IVSHG1A?

It is a Feedback Shield Board developed by GE.

How does the board contribute to system reliability?

By protecting the IVFB board, IVSH enhances system reliability, ensuring uninterrupted operation of the drive system and minimizing downtime.

How is hardware compatibility maintained within the system?

Each cable connector on the terminal board features its own identification (ID) device, enabling the system to detect any mismatches and ensure seamless integration and compatibility.