SPECIFICATIONS

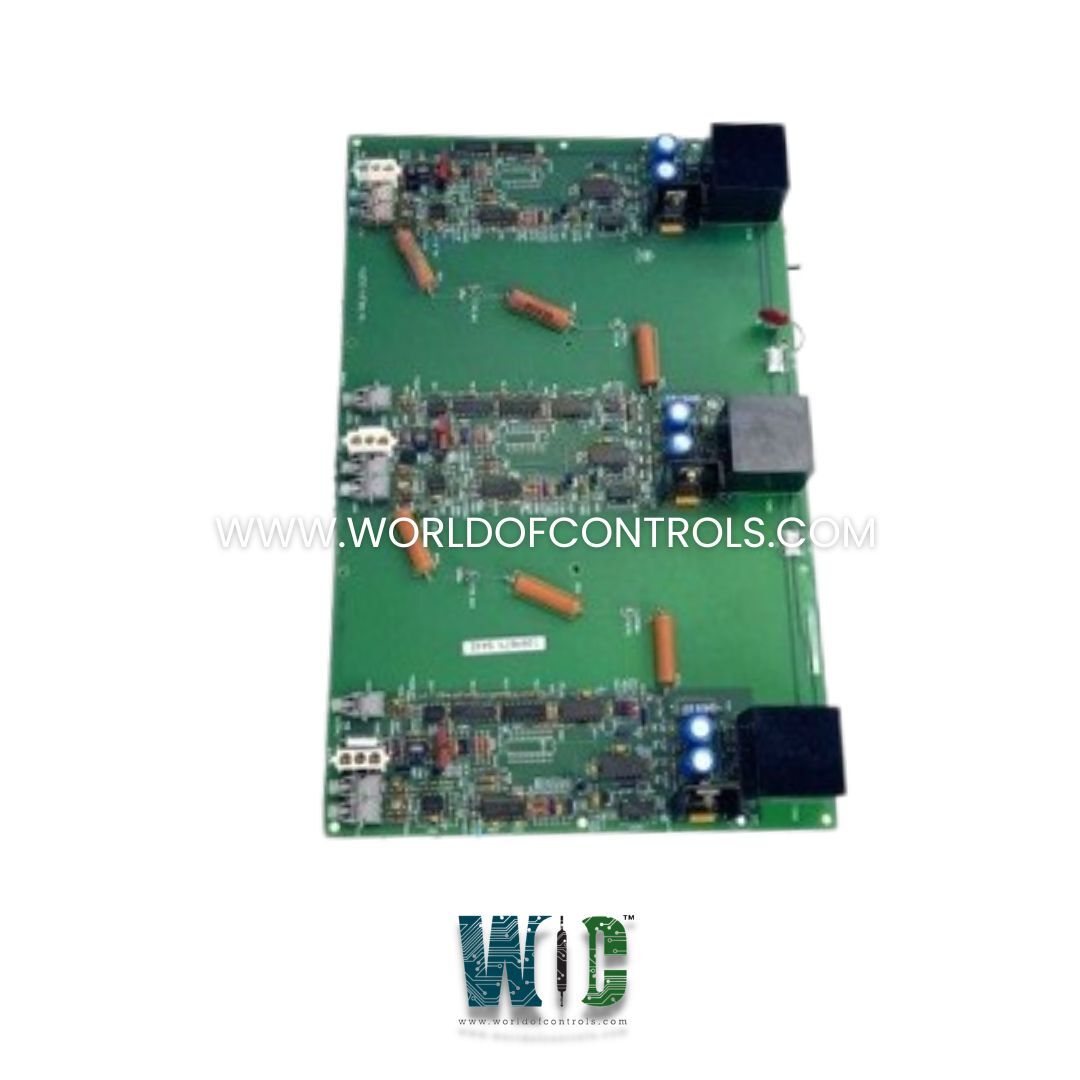

Part No.: IS200IVFBG1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Current Feedback Board

Repair: 3-5 Days

Availability: In Stock

Series: EX2100

Functional Description

IS200IVFBG1A is a Current Feedback Board developed by GE. It is a part of EX2100 excitation system. The Current Feedback Board, developed by GE, plays a critical role within the excitation system, specifically in applications involving a 3-level pulse-width modulated (PWM) inverter. Positioned within the load cabinet of the series, this board is integral to ensuring precise current feedback control, thereby enhancing the overall efficiency and performance of the system.

Features

- Designed with precision and reliability in mind, it enables the accurate measurement and regulation of key parameters that are vital for maintaining the stability and efficiency of power generation units.

- Ensures that the excitation system operates at optimal levels by providing real-time current feedback to the main control system. This feedback helps in regulating the generator's field current, which directly influences the output voltage and overall performance of the generator. The board's design is optimized for high accuracy and fast response times, making it an essential component in ensuring the reliability and efficiency of the excitation system.

- Equipped with specialized circuitry to measure the current feedback accurately, ensuring that the control system receives precise data for dynamic adjustment and regulation. This feedback loop is critical for maintaining the correct operating conditions of the generator, ensuring that the system remains within desired operating parameters, especially under varying load conditions. By integrating this board into the EX2100 system, GE provides an effective solution for controlling and monitoring field currents, enhancing the overall performance and longevity of power generation equipment.

- This board is designed to seamlessly integrate with the EX2100 excitation system, allowing for efficient communication and data transfer within the control network. Its compact, robust design makes it suitable for use in harsh industrial environments, where accurate feedback and system stability are essential.

Installation and Integration

- Phase Leg Assembly: The Phase Leg Assembly forms the fundamental structure responsible for managing electrical phases within the 3-level pulse-width modulated (PWM) inverter system. Comprising semiconductor devices arranged strategically, it controls the switching operations that regulate current flow and voltage output. The Current Feedback Board plays a critical role in this assembly by continuously monitoring and precisely adjusting current levels, ensuring efficient power conversion and optimal performance of the inverter system.

- Back Base: Providing robust structural support and secure mounting points, the Back Base ensures the stability and proper alignment of various components within the load cabinet. It anchors the Current Feedback Board and other critical modules in place, safeguarding against vibrations and mechanical stresses that could affect operational reliability. This structural integrity is essential for maintaining consistent performance and facilitating ease of maintenance when necessary.

- Interface Module: The Interface Module acts as a pivotal intermediary within the excitation system, facilitating seamless communication and control interfaces between different system elements. It enables data exchange and synchronization between the Current Feedback Board, Phase Leg Assembly, and other subsystems. This coordination ensures cohesive operation and efficient management of system functions, enhancing overall reliability and responsiveness to operational demands.

- Capacitor Assembly Module: Central to energy storage and voltage stabilization, the Capacitor Assembly Module stores electrical energy and smoothens voltage levels within the inverter system. It absorbs transient currents and maintains stable voltage outputs, contributing to the system's reliability under varying load conditions. The Current Feedback Board collaborates closely with this module to regulate current feedback accurately, supporting consistent power delivery and minimizing fluctuations that could impact system performance.

- Blower Assembly: Critical for thermal management, the Blower Assembly provides essential cooling to maintain optimal operating temperatures for components housed within the load cabinet. By regulating heat dissipation, it prevents overheating and ensures the longevity and reliability of sensitive electronic parts, including the Current Feedback Board. Effective cooling is essential for sustaining performance accuracy and operational efficiency under demanding industrial environments.

- Cable Assemblies: Interconnecting various subsystems and components, Cable Assemblies establish essential electrical pathways for power distribution and signal transmission within the load cabinet. They facilitate seamless integration and communication between the Current Feedback Board, Phase Leg Assembly, Interface Module, and other critical system elements. This interconnectedness ensures coordinated operation and efficient energy management throughout the excitation system.

- AC Buswork: As the primary conduit for distributing AC power, the AC Buswork ensures efficient and reliable power supply to all components within the excitation system. It distributes electrical energy from the source to different modules, including the Current Feedback Board, ensuring consistent and stable operation. The board’s integration with the AC Buswork is crucial for maintaining system integrity and optimizing performance, supporting continuous power generation processes without interruptions.

System Software Features

- The exciter system is designed with a high degree of flexibility and modularity, enabling it to be configured in various ways to suit different operational needs. This flexibility allows for a range of output currents and provides options for implementing different levels of redundancy within the system. Depending on the specific requirements of the application, operators can choose from configurations that include power from potential transformers connected to generator terminals, compound sources, or auxiliary sources via excitation transformers linked to auxiliary buses. These choices ensure that the exciter system can adapt seamlessly to different power distribution setups and operational scenarios.

- Redundancy is a key feature of the exciter system, offering options such as single or multiple bridges, warm backup bridges, and simplex or redundant controls. These redundancy options are critical for enhancing system reliability and minimizing downtime. Single bridges provide basic functionality, while multiple bridges allow for increased capacity and reliability by distributing load across multiple units. Warm backup bridges ensure rapid failover in case of primary bridge failure, maintaining continuity of operation without significant interruption. Similarly, simplex or redundant controls provide flexibility in how control signals are managed, ensuring that even in the event of control system failure, backup mechanisms can seamlessly take over to maintain operation.

- Feedback mechanisms within the exciter system are essential for monitoring and controlling performance. Key inputs include feedback from generator line current and stator output voltage, which are used to regulate and adjust the excitation levels. By monitoring these parameters closely, the exciter system can optimize its outputs of DC voltage and current to the exciter field. This controlled output is crucial for adjusting the magnetic field strength within the generator, thereby influencing voltage regulation and overall power quality.

The WOC team is always available to help you with your EX2100 requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200IVFBG1A?

It is a current feedback board developed by GE under the EX2100 series.

What are the primary power sources for the exciter system?

The exciter system can be powered from various sources, including potential transformers connected directly to the generator terminals, compound sources, or through excitation transformers linked to auxiliary buses. These options provide flexibility to adapt to different power distribution setups and operational requirements.

What redundancy options are available in the exciter system?

Redundancy options include single or multiple bridges, warm backup bridges for rapid failover, and simplex or redundant controls. Single bridges provide basic functionality, while multiple bridges distribute load for increased capacity. Redundant controls ensure operational continuity by switching to backup systems in case of primary component failure.

How does the exciter system utilize feedback for control purposes?

The exciter system relies on feedback mechanisms such as generator line current and stator output voltage. These inputs are critical for monitoring and adjusting excitation levels to maintain stable generator operation and optimal power output.