World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200GGXIG5A - Expander Load Source Board is available in stock which ships the same day.

IS200GGXIG5A - Expander Load Source Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200GGXIG5A - Expander Load Source Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

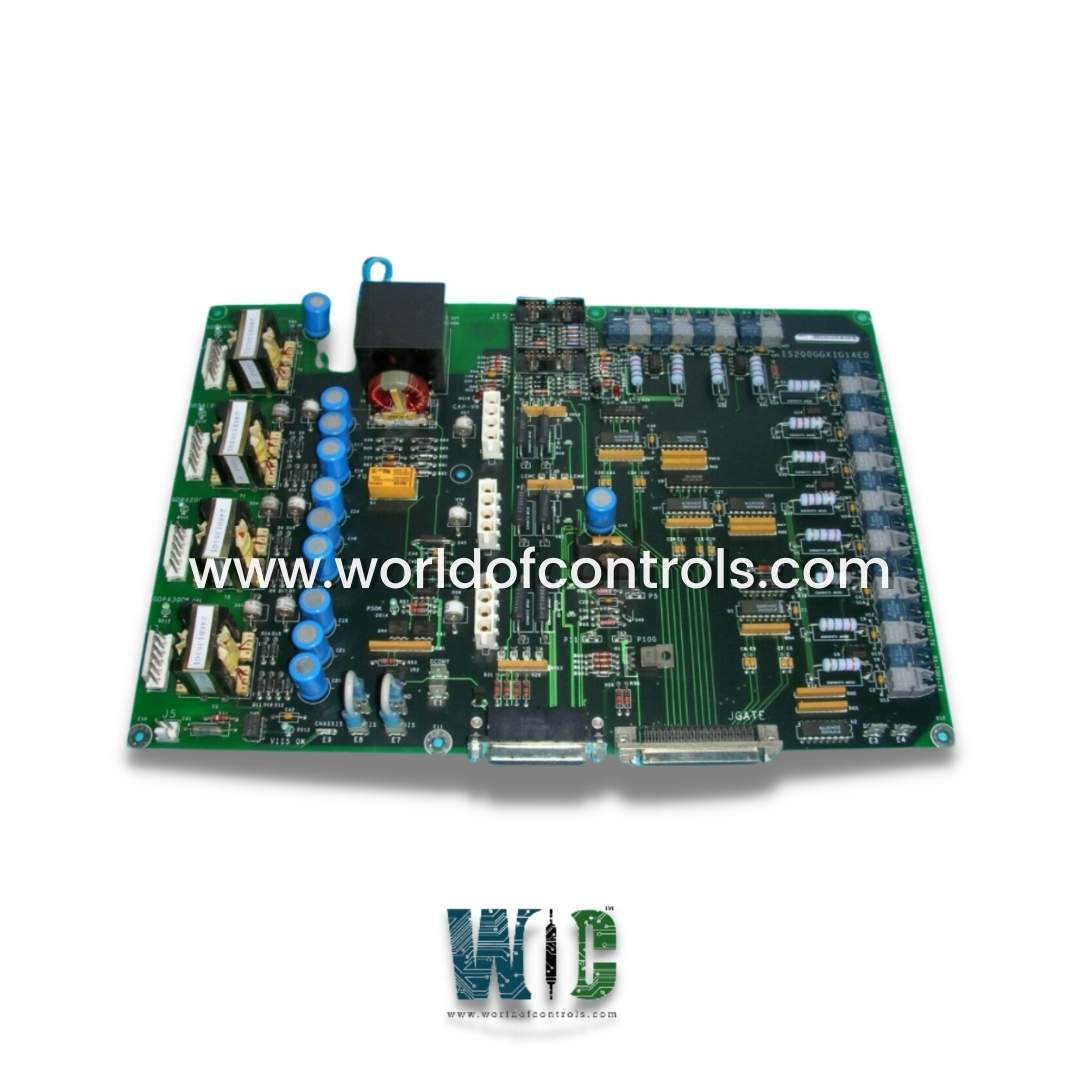

Part Number: IS200GGXIG5A

Manufacturer: General Electric

Series: Mark VI

Product Type: Expander Load Source Board

Number of inputs: 3x4 passive

Number of outputs: 2

Input Signals: RS-422 / Digital

MPU pulse rate range: 2 Hz to 20 kHz

Voltage Range: 18 - 32 VDC

Power Supply Input: 5 VDC

Mounting: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to 65°C

MPU input circuit sensitivity: 27 mV pk

Size: 33.0 cm high x 17.8 cm

Repair: 3-7 Days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS200GGXIG5A is an Expander Load Source Board manufactured and designed by General Electric as part of the Mark VI Series, which is used in GE Speedtronic Gas Turbine Control Systems. It provides galvanic isolation between high-voltage power devices, including IGCTs, thyristors, and other switching elements, and low-voltage digital control logic, ensuring electrical protection and signal integrity. The board accepts RS-422 or equivalent control signals from the control rack, converts them into optically or electrically isolated outputs, and drives the gate circuits of the power bridge. It also collects feedback signals, including gate status, voltage, and current measurements, and routes these signals back to BICI and BPII interface boards for system monitoring, diagnostics, and fault detection.

INSTALLATION:

The board must be handled using full ESD protection procedures, including anti-static packaging, grounded wrist straps, and ESD-safe tools to prevent damage to sensitive components. Before installation, all system power must be completely isolated and verified following Lock-Out/Tag-Out (LOTO) safety protocols. The board should be mounted using specified standoffs, screws, and star washers to ensure secure mechanical support and proper grounding of analog and digital reference planes. All connectors—including power input, gate-drive outputs, feedback signals, and communication interfaces—must be correctly aligned, fully seated, and secured to prevent intermittent contact or signal integrity issues. Verification of connector pinout, grounding, and mechanical alignment should be performed before energizing the system to ensure proper operation and safety.

OPERATION:

The Expander Load Source Board electrically isolates low-voltage control logic from high-voltage power bridge circuits while converting RS-422 or equivalent control commands into optically or electrically isolated outputs to drive IGCTs, thyristors, or other switching devices. It distributes regulated power from the system power supply to gate-drive circuits, isolation modules, and diagnostic components. Simultaneously, the board collects feedback signals, including gate status, voltage, and current measurements, and routes them to BICI and BPII interface boards for real-time monitoring, diagnostics, and fault detection. The board maintains signal integrity through segregated analog and digital ground planes, minimizing noise coupling and ensuring reliable low-latency communication between the control logic and high-power switching devices. Operational status is monitored via LED indicators and test points, enabling verification of gate outputs, feedback continuity, and system health without disrupting normal control functions.

WOC maintains the largest inventory of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems, providing immediate access to critical components. Our stock includes unused parts, refurbished boards, and specialized components, all curated to meet stringent quality standards. In addition to supplying parts, we offer expert repair and refurbishment services for malfunctioning boards, with every unit backed by a warranty to ensure reliability and long-term performance.

Our team of experienced professionals is available 24/7 to support OEM requirements and maintain seamless operation of your automation systems. We provide guidance on part selection, troubleshooting, and repair solutions, delivering responsive and knowledgeable assistance. For detailed information on pricing, availability, or specific service requests, please contact our team via phone or email for prompt, personalized support tailored to your operational needs.

What is the IS200GGXIG5A?

It is an Expander Load Source Board manufactured by General Electric for the Mark VI Speedtronic Gas Turbine Control System, providing isolation and signal interfacing between high-voltage power devices and low-voltage control logic.

What type of signals does the Expander Load/Source Board support?

The board accepts RS-422 or digital input signals from the control rack. It converts these into isolated outputs to drive high-power switching components. It also manages feedback signals for system diagnostics and fault detection.

What is the sensitivity of the MPU input circuit?

The MPU input circuit has a sensitivity of 27 mV peak, allowing detection of very low-level pulse signals. This supports accurate speed feedback across a wide frequency range from 2 Hz to 20 kHz.

How does the board ensure noise immunity and signal integrity?

The GGX board uses segregated analog and digital ground planes to minimize cross-coupling between high-frequency gate-drive signals and low-level feedback circuits. Differential signaling and shielded connector interfaces mitigate EMI and electrical noise. This design ensures stable operation in high-power turbine environments.