SPECIFICATIONS

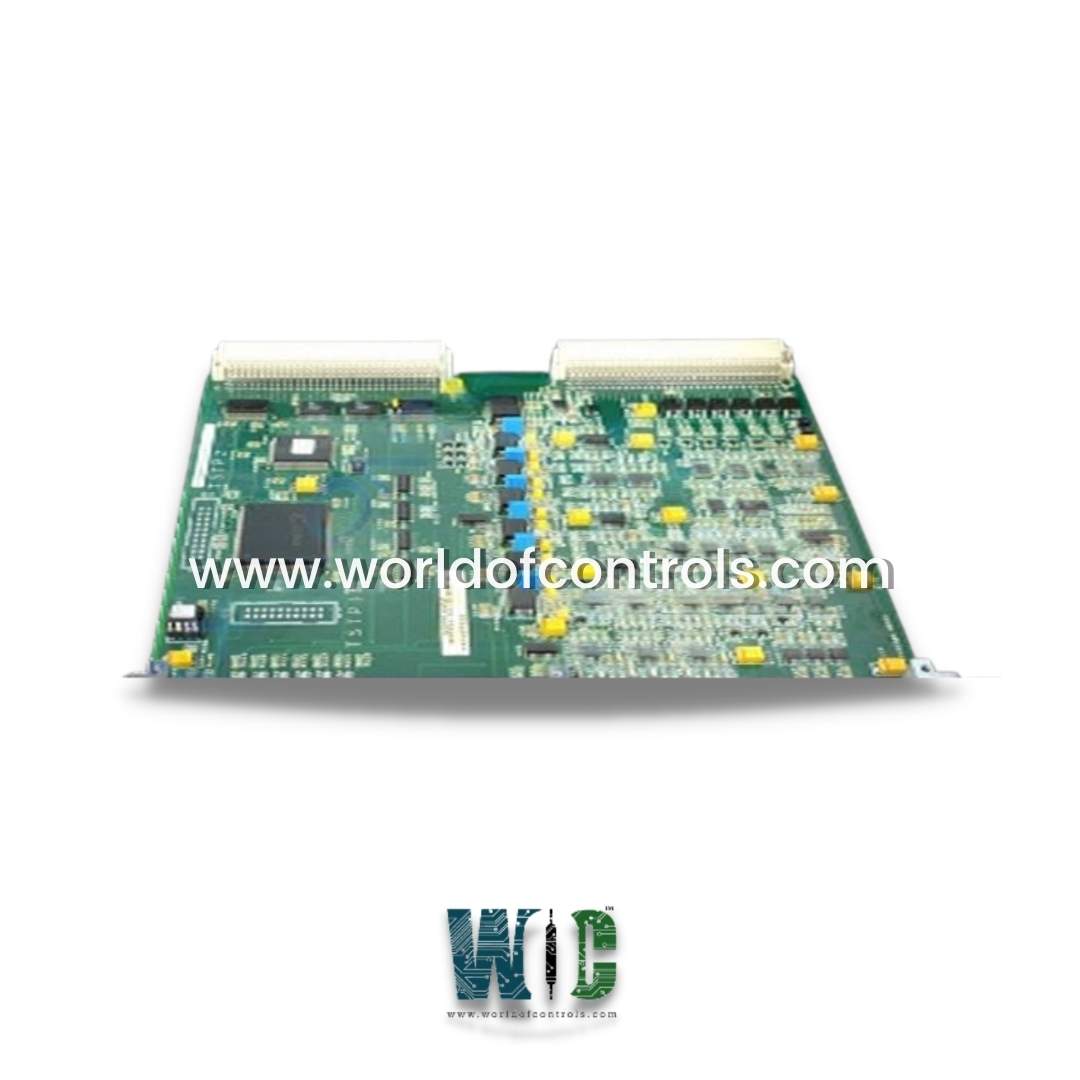

Part Number: IS200FCGEH1A

Manufacturer: General Electric

Series: LCI

Product Type: LCI Control and Gating-Exciter Board

No.of Analog Voltage Inputs: 6

No.of LEDs: Two, Active and IMOK

No.of Ribbon Cable Connectors: Two, 20-pin

No.of VMEbus Connectors Two, 96-pin

Country of Manufacture: United States (USA)

Functional Description

IS200FCGEH1A is an LCI control and gating-Exciter board developed by General Electric. It is a part of the LCI Series used in GE Gas Turbine Control Systems. The board is specifically designed to interface between the DSPC processor board and the motor excitation bridges within the LCI system, playing an essential role in signal conditioning and gating control.

Features

- The FCGE board provides the necessary electrical interface between the motor field exciter and the LCI drive. Its main role is to condition voltage and current feedback signals received from the exciter bridge before relaying them to the LCI processor board for processing and control. Additionally, it relays gating commands from the LCI processor board to the exciter, ensuring precise control and synchronization of the excitation system.

- The board is mounted on the VMEbus rack inside the LCI control cabinet and connects to the VPBL backplane via a VMEbus connector. Through this interface, it communicates with other boards in the system, contributing to the overall control and monitoring of the LCI and turbine operation.

- Voltage and Current Feedback Conditioning: The FCGE board processes analog feedback signals from the exciter bridge, converting them into conditioned signals suitable for the LCI processor board. This ensures accurate monitoring and stable control of excitation levels.

- Control Gating Power: It manages and distributes gating power signals, coordinating with the LCI processor to control the exciter cells efficiently.

- Heartbeat Monitoring: The board includes a built-in heartbeat function that is triggered when the VMEbus host first writes to the FCGE. When the system operates correctly, the active LED indicator turns green. If a fault or communication failure is detected, gating is disabled and the LED indicator turns off. This function acts as a built-in diagnostic mechanism to enhance system reliability and safety.

- Signal Interfacing: The board ensures seamless communication between the exciter, processor, and other LCI components, maintaining synchronization and stable operation.

Connectors and Interfaces

- P1 Connector: Standard VMEbus I/O connector, used for primary communication with the system backplane and other control modules.

- P2 Connector: Dedicated for I/O interfacing between the host processor, exciter, and LCI boards, allowing for expanded communication and control capabilities.

Mounting and Configuration

Mounted within the VMEbus rack located in the LCI control cabinet. This modular design enables easy installation, replacement, and maintenance. The board’s robust construction and high signal integrity make it suitable for demanding industrial and turbine control applications.

VMEbus Interface

- The FCGE environment consists of an FCGE board and a VMEbus host processor.

- The FCGE is both electrically and physically compatible with the VME (A24/D16) specification. All standard VMEbus signals are routed to the VMEbus backplane via the P1 connector. The FCGE decodes the vast majority of the 24 address bits used for internal addressing.

- Through the P2 connector, the FCGE communicates with the host processor, other LCI boards, and the exciter. A 34-pin ribbon connector connects the exciter to the VMEbus backplane.

Indicators

Two green LEDs are located on the board's front:

- IMOK (DS1) blinks to indicate okay - it passed selftest and is operational.

- When communicating with the LCI processor board, ACTIVE (DS2) is solid.

I/O connectors

- The I/O connectors form an essential bridge between various components within the system, enabling seamless communication and data exchange. Within the context of the FCGE, these connectors serve as crucial interfaces that define the interaction between different modules and peripherals.

- The FCGE unit encompasses two distinct 96-pin VMEbus connectors, each playing a distinct role in facilitating communication and connectivity.

- The P1 connector is dedicated to standard VMEbus I/O operations, acting as the designated port through which various inputs and outputs are routed. This connector acts as a hub for data exchange between the FCGE and external devices, making it a pivotal point in the unit's functionality. The information exchanged via this connector adheres to the standardized VMEbus protocol, ensuring compatibility with a wide array of peripheral devices.

- On the other hand, the P2 connector serves as a versatile interface, connecting the FCGE unit to the host processor, other LCI boards within the system, and the exciter module. This connector's flexibility enables diverse interactions, allowing the FCGE to not only communicate with the central processing unit but also establish connections with other components and modules present in the setup. These connections foster collaborative functionality, enabling efficient data sharing and coordination among different subsystems.

- In addition to the primary connectors, there are two 20-pin ribbon cable connectors named TSTP1 and TSP2. These connectors, although not intended for regular operational use, play a crucial role during the factory testing phase. They provide a direct interface for diagnostic and testing equipment, allowing for comprehensive assessments of the FCGE's performance and functionality. This demonstrates a meticulous approach to quality assurance and validation, ensuring that each unit meets stringent standards before deployment.

Firing commands

- Firing commands within the context of the FCGE serve as the orchestration signals that govern the operation of the exciter module. The exciter, a pivotal component in various power electronics systems, relies on these commands to regulate the behavior of its silicon-controlled rectifier (SCR) cell strings.

- The unit is equipped with specialized drivers specifically designed to manage six firing command outputs, each of which corresponds to a distinct SCR cell string within the exciter bridge. This correspondence establishes a direct link between the FCGE and the exciter's internal circuitry, allowing for granular control over each SCR cell string's activation and deactivation. The importance of these firing commands lies in their ability to dictate when the SCRs within the cell strings are triggered, thus regulating the flow of current and voltage in the power electronics system.

- Control over the firing command drivers is vested in the LCI processor, a key component of the unit. The LCI processor acts as the central intelligence, facilitating communication between various subsystems and modules within the FCGE and beyond. By interfacing with the firing command drivers, the LCI processor wields the capability to enable or disable up to six firing command outputs simultaneously. This level of control empowers the LCI processor to synchronize the firing of multiple SCR cell strings, allowing for precise modulation of power flow and distribution.

WOC has the largest stock of GE Distributed Gas Turbine Control System Replacement Parts. Our team of experts at WOC is happy to assist you with any of your automation requirements. Contact us for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IS200FCGEH1A?

It is a LCI control and gating-Exciter board developed by General Electric.

What is the function of the FCGE board?

The FCGE board's main function is to condition voltage and current feedback signals from the exciter bridge to the LCI processor board. It also provides control gating power for the motor field exciter and LCI drive.

What is the VPBL backplane?

The VPBL backplane is a high-speed data bus used for communication between various circuit boards in a system. In this case, the FCGE board is connected to the VPBL backplane's VMEbus connector.

What is an LCI drive?

LCI stands for Line Commutated Inverter, which is a type of variable frequency drive used to control the speed of large AC motors. The LCI drive consists of several circuit boards, including the DSPC board, FCGE board, and LCI processor board, that work together to control the motor's speed and torque.