World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

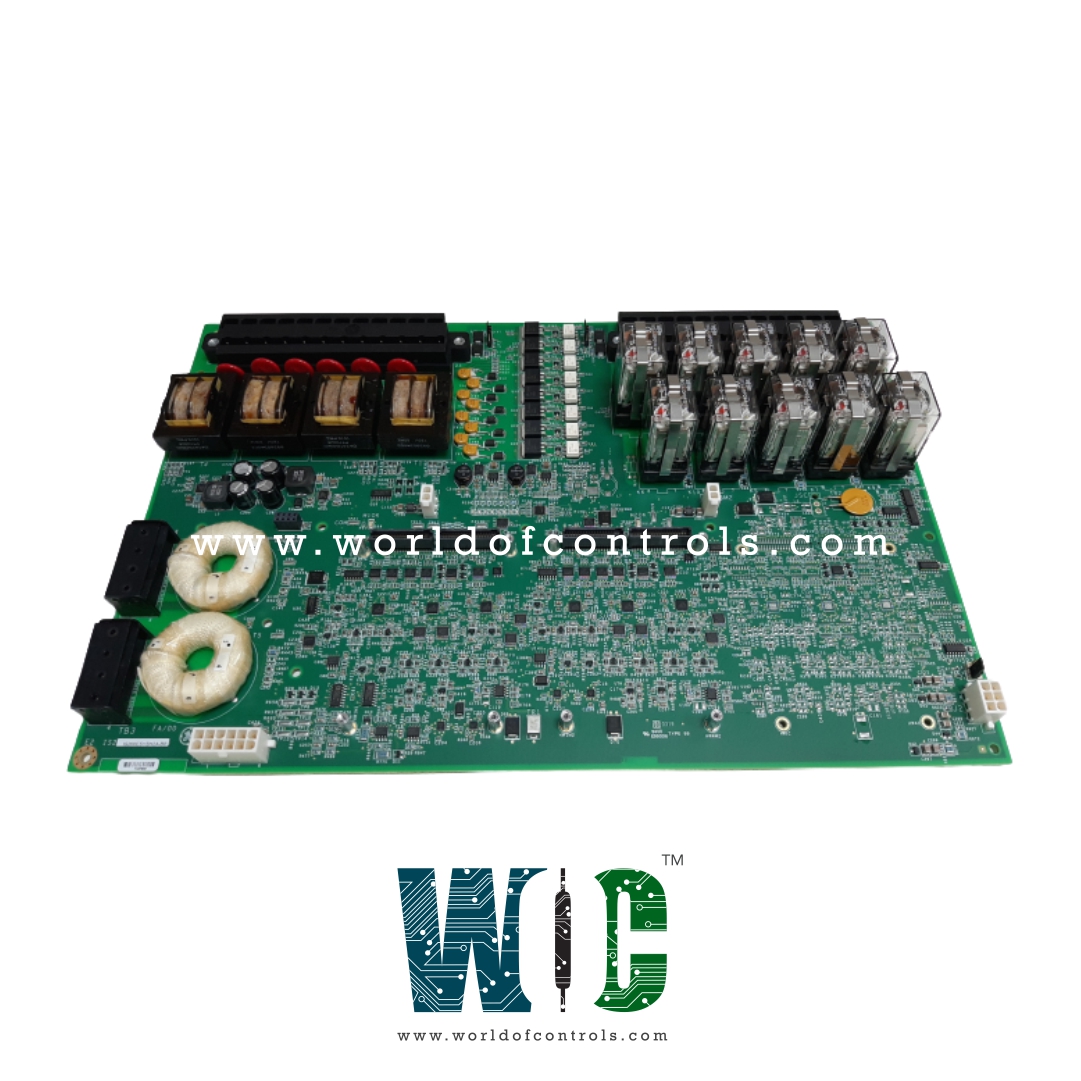

IS200ESYSH2A - Excitation Control System I/O Interface Module is available in stock which ships the same day.

IS200ESYSH2A - Excitation Control System I/O Interface Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200ESYSH2A - Excitation Control System I/O Interface Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200ESYSH2A

Manufacturer: General Electric

Series: EX2100e

Product Type: Excitation Control System I/O Interface Module

Number of channels: 12

Common Mode Voltage Range: +5 V dc

Maximum Lead Resistance: 15 Ohm

Analog output current: 0-20 mA

Operating temperature: -30 to 65 °C

Size: 8.26 cm high x 4.18 cm

Frequency: 50 or 60 Hz

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

Manual: GEA-S1301A

FUNCTIONAL DESCRIPTION:

IS200ESYSH2A is a Discrete Simplex DIN-Rail Module manufactured and designed by General Electric as part of the EX2100e Series used in GE Excitation Control Systems. The EX2100e Excitation Control Regulator system is GE’s most recent state-of-the-art control system for steam, gas, or hydro generators for both new and retrofit units. Control hardware and software design is closely coordinated between GE’s system and controls engineering to ensure the delivery of a true system solution. Integration is seamless between Excitation Control systems, Turbine Control systems, Static Starter Control systems, Integrated Control Systems (ICS), and the Human-machine Interface (HMI). For stand-alone retrofit applications, integration with customer-distributed control systems (DCS) through serial or Modbus Ethernet is supported.

An Excitation Control System I/O Interface Module is a crucial component in the management and regulation of power generation systems. It functions as the link between the excitation control system and various hardware components like the generator’s excitation system, sensors, and actuators. Its primary role is to convert input signals, whether analog or digital, into formats that can be understood and processed by the control system. This ensures that the generator’s excitation system can be adjusted accordingly, allowing for stable and efficient power generation.

The I/O interface module is responsible for acquiring data from a variety of sensors that monitor key parameters such as voltage, current, and temperature. These readings are vital for analyzing the generator’s performance and ensuring its operation within safe parameters. The module then transmits this data to the excitation control system, which makes the necessary adjustments to maintain optimal generator performance.

FUNCTIONS:

WOC has the largest stock of Replacement Parts for GE Excitation Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is an Excitation Control System I/O Interface Module?

The Excitation Control System I/O Interface Module is a component that facilitates communication between the excitation control system and physical hardware, such as sensors, actuators, and the generator’s excitation system. It handles signal conversion, data acquisition, control output, and communication.

Why is signal conversion important in an I/O Interface Module?

Signal conversion ensures that the data collected from sensors is in a format that the excitation control system can process and analyze. This enables accurate control of the excitation system to maintain generator stability and performance.

How does the module enhance the efficiency of the excitation system?

By providing precise control signals, real-time data acquisition, and seamless integration with other systems, the module ensures optimal excitation system performance, leading to improved generator stability and power quality.