World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200DTCCH1A - DIN Rail Contact Output Module is available in stock which ships the same day.

IS200DTCCH1A - DIN Rail Contact Output Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200DTCCH1A - DIN Rail Contact Output Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

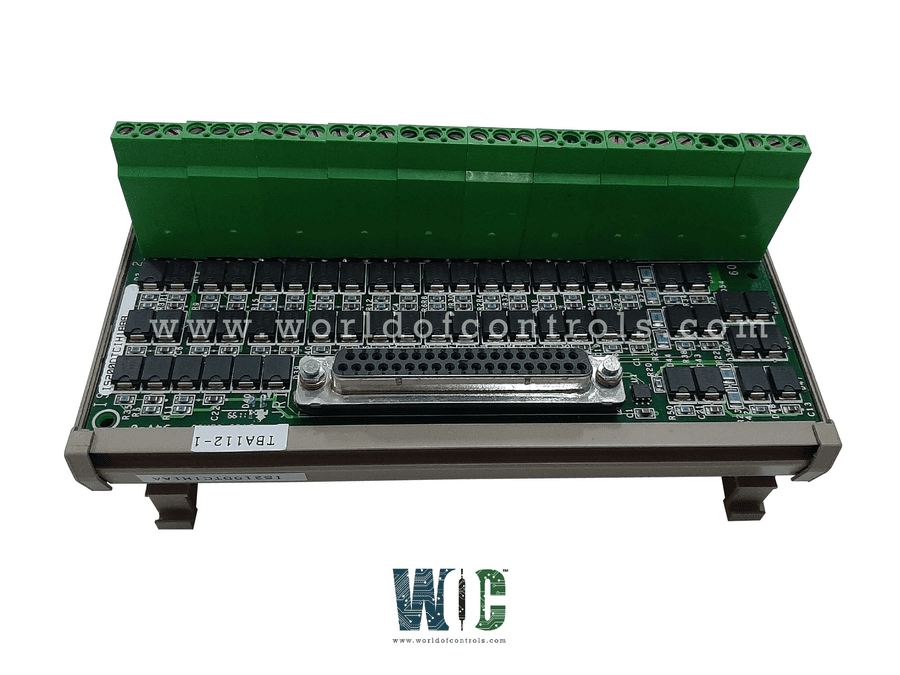

Part Number: IS200DTCCH1A

Manufacturer: General Electric

Series: Mark VIe

Product Type: DIN Rail Contact Output Module

Number of Output Channels: 12

Power Supply Requirements: +5 VDC

Contact Rating: 2 A at 30 VDC

Dielectric Withstand Voltage: 1500 V RMS

Operating temperature: -30 to +65°C

Mounting Type: DIN Rail

Compliance: CE, UL, and RoHS compliant

Size: 30.48 cm × 21.33 cm

Backplane Connectors - P1, P2

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS200DTCCH1A is a DIN Rail Contact Output Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. It is designed to provide reliable binary outputs using electromechanical relay contacts. The module outputs are typically used for controlling external devices such as solenoid valves, contactors, signal lamps, alarms, and interlocking circuits. Each output channel provides a dry contact Form A (normally open) relay, allowing the control system to open or close circuits with complete electrical isolation from the control logic. The relay contacts are capable of switching both AC and DC loads and are protected against contact welding and transient overvoltage. Designed with robustness and industrial-grade performance in mind, the IS200DTCCH1A ensures long operating life and safe switching in mission-critical turbine and process environments. It also supports channel-by-channel control, with the ability to handle output logic independently, making it suitable for flexible I/O configurations in both centralized and distributed control architectures.

INSTALLATION:

The module connects to the system backplane through dual connectors (P1 and P2), which supply both communication lines and power. Proper installation requires adherence to environmental and electrical guidelines provided by GE to ensure safe and efficient performance. The module should be mounted vertically with sufficient clearance for heat dissipation and access to wiring terminals. Wiring to external devices is done via screw-type terminal blocks that offer secure and vibration-resistant connections. Field wiring must be routed carefully to avoid electromagnetic interference (EMI) and to maintain channel isolation. Grounding and shielding practices must be observed to prevent ground loops and signal interference. Additionally, installers must ensure that all wiring conforms to applicable electrical codes and safety standards to avoid load overcurrent and short circuits.

OPERATION:

Each output channel operates independently, enabling or disabling external circuits based on control logic executed within the Mark VIe CPU. The module provides a visual status indication using onboard LEDs for each output, allowing operators to verify the output status in real time. These outputs are typically used in applications where precise on/off control of equipment is required, such as motor start/stop commands, alarm triggering, or interlock engagement. The relay contacts are rated for industrial loads and are built to withstand frequent switching cycles with minimal wear. The module is also designed to handle momentary or sustained output commands, depending on system requirements.

COMPATIBILITY:

It integrates with the Mark VIe I/O network architecture using standard protocols and configuration tools. The module is supported by GE’s ToolboxST software, which allows for configuration, diagnostics, and real-time monitoring. It can be used with various controller types within the Mark VIe system and supports flexible mapping of output points based on system architecture. This makes it suitable for a wide range of industrial applications, including gas turbines, steam turbines, hydro turbines, and balance-of-plant operations. The module also supports backward and forward compatibility with other I/O modules in the Mark VI and Mark VIe families, facilitating system upgrades or expansions. Its standardized mechanical and electrical interface ensures it can be easily integrated into new installations or as a replacement in existing systems.

WOC has the largest stock of OEM Replacement Parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a DIN Rail Contact Output Module?

A DIN Rail Contact Output Module is an industrial automation component that provides discrete (on/off) control outputs using relay contacts. It is mounted on a DIN rail inside a control panel and connects a controller (like a PLC or DCS) to field devices such as lights, solenoids, alarms, or contactors.

What type of loads can this module control?

DIN Rail Contact Output Modules typically control resistive or inductive loads, such as signal lamps, small motors, relays, solenoids, or alarms. Output relays can usually handle up to 2 A at 30 VDC or 250 VAC, depending on the model.

How does the module function within a control system?

The module receives control signals from the CPU/controller and switches its onboard relays accordingly. Each relay represents one output channel that opens or closes an external circuit. This allows precise on/off control over connected devices like solenoid valves, contactors, and status lights.