World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

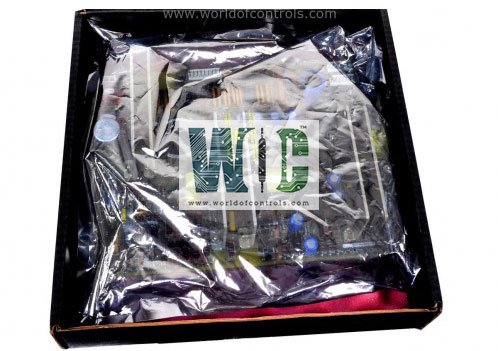

IS200AVSCG1A - SCR Source Rectifier Control Board is available in stock which ships the same day.

IS200AVSCG1A - SCR Source Rectifier Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200AVSCG1A - SCR Source Rectifier Control Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200AVSCG1A

Manufacturer: General Electric

Series: EX2100

Type: SCR Source Rectifier Control Board

Control Signal Input: Phase-synchronized analog/digital signals

Input Control Voltage: 110�125 V DC

Humidity Range: 5% to 95%

Mounting: 4 mounting holes

Isolation Voltage: 1500 V RMS

Power Consumption: 5 W

Operating Temperature Range: 0�C to 60�C

Size: 30.48cm High x 21.33cm

Repair: 3-7 days

Availability: In Stock

Weight: 0.65 kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS200AVSCG1A is a SCR Source Rectifier Control Board manufactured and designed by General Electric as part of the EX2100 Series used in GE Excitation Control Systems. It is an advanced SCR Source Rectifier Control Board engineered to manage and trigger silicon-controlled rectifiers (SCRs) within high-power conversion systems, such as the GE EX2100 Excitation Control System. This board controls the timing and synchronization of SCR firing pulses to regulate the conversion of three-phase AC input into controlled DC output for generator field excitation. It receives voltage and current reference signals from the excitation regulator, processes them using onboard logic, and produces phase-synchronized gate pulses to the associated power semiconductors. Integrated protection and diagnostic features enable the board to detect conditions such as phase loss, firing failure, or SCR conduction errors. LEDs such as SCOK and IMPOK provide visual status for operational integrity.

INSTALLATION:

It is mounted on a designated slot within a GE control cabinet or power electronics rack, often as part of an excitation bridge assembly. It is secured using four corner mounting points and interfaces with the system through several plug-and-socket connectors, which link to firing circuits, voltage, and current feedback sources, and bridge interface components. Installation must be performed under anti-static conditions to avoid damage to sensitive components. Proper grounding, cable routing, and connector mating are essential to ensure signal integrity and safe operation. The environment should be clean, dry, and temperature-controlled, as specified by GE�s system guidelines. All wiring and hardware must comply with industrial safety standards such as UL508A and CSA 22.2 No.14, especially in systems operating in high-voltage environments.

OPERATION:

The IS200AVSCG1A governs SCR firing by generating phase-controlled pulses in synchronization with the incoming AC waveform. By adjusting the firing angle of the SCRs, the board precisely controls the level of DC voltage delivered to the generator field. It continuously monitors line voltage, feedback current, and synchronization signals to optimize bridge performance under varying load and system conditions. In coordination with the excitation control unit, the AVSC supports operational features such as soft start, field build-up, and dynamic response to grid disturbances. Fault conditions such as firing misalignment, overcurrent, or loss of phase input are immediately detected, with status alerts sent to the system controller for protective action. The board�s fast response and control accuracy ensure stable excitation and contribute to overall generator reliability and grid compliance.

COMPATIBILITY:

The board is designed for integration with GE EX2100 and EX2100e excitation systems and is compatible with various GE firing and feedback modules, including gate pulse amplifiers and bridge interface boards. It supports configurations for 6-pulse and 12-pulse bridge systems and may be used in redundant or parallel excitation architectures. Communication and synchronization with the main control system are achieved via standard backplane connectors, and configuration is managed using ToolboxST or GE�s dedicated excitation software tools. While it is not directly interchangeable with earlier analog systems like the EX2000, it can be used in retrofit applications where system upgrades include modern digital controllers and bridge hardware. Compatibility must be verified based on system firmware, firing circuit topology, and field voltage/current ratings.

WOC maintains the largest inventory of OEM replacement parts for GE Excitation Control Systems, including unused and fully refurbished boards, all backed by a comprehensive warranty. We also provide complete repair services for faulty boards, restoring them to peak performance, while our experienced technical team is available 24/7 to support all your OEM and automation needs. Whether you require immediate parts, cost-effective refurbished options, or expert repair services, we deliver reliable, tailored solutions. For pricing, availability, or service inquiries, contact us via phone or email.

What is the IS200AVSCG1A?

The IS200AVSCG1A is a GE-manufactured SCR Source Rectifier Control Board, part of the EX2100 excitation control system. It regulates SCR firing to produce a controlled DC output for generator field excitation. The module integrates fault diagnostics, status indicators, and isolation circuitry to ensure safe operation.

What is its primary function?

It provides precise phase-controlled rectification of AC to DC for generator excitation. The board monitors SCR conduction, line voltage, and feedback from the generator field to maintain stable output. It also generates fault signals in case of SCR misfire, overvoltage, or short circuits.

What function does the board serve in an excitation system?

The board generates phase-synchronized firing pulses for SCRs, enabling precise control of the DC output voltage applied to the generator field. It ensures stable excitation under both steady and dynamic conditions and responds rapidly to load changes or system disturbances.

How does the board communicate with other modules?

Communication is accomplished through edge connectors and ribbon cables that link the AVSC board to gate driver modules such as EGDM or ESEL, as well as to the control backplane or VMEbus architecture used in the EX2100 system. The board receives commands (like bridge enable, pulse inhibit, or timing adjustments) from the system controller and also sends status signals back, enabling real-time feedback and fault monitoring.