World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IC697RCM711 - Redundancy Communication Module is available in stock which ships the same day.

IC697RCM711 - Redundancy Communication Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC697RCM711 - Redundancy Communication Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

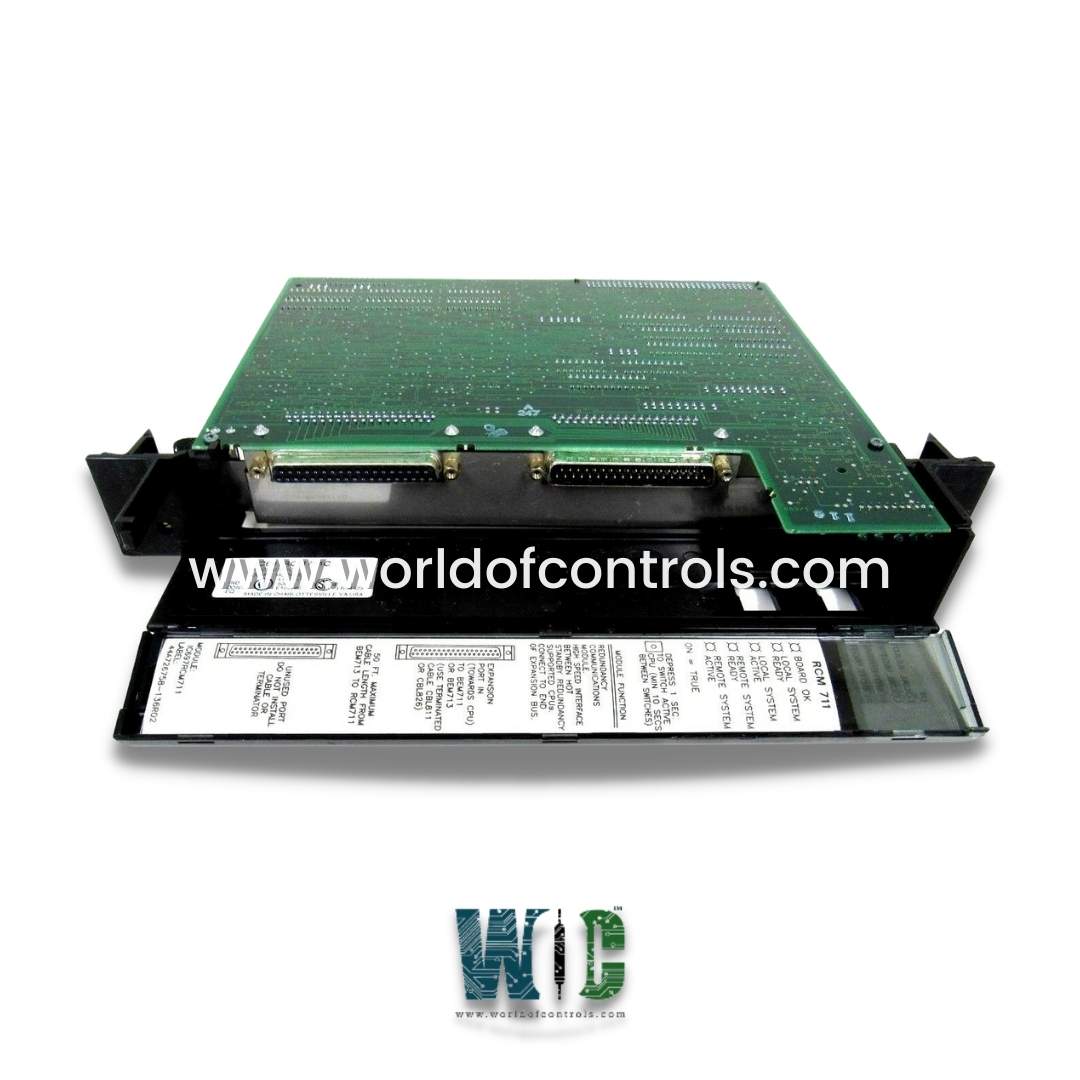

Part No: IC697RCM711

Manufacturer: General Electric Fanuc

Product Type: Redundancy Communication Module

Series Series 90-70

Type: Communication Module

Purpose: Redundancy system

Maximum cable length: 50 feet

Current required from 5V Bus: 1.2 A

Backplane Current draw: 1.2 Amperes

Maximum cable length: 15 m

Effective data rate: 500 Kbytes / sec

Size: 8.83 x 3.58 x 4.7 inches

Product Lifecycle: Discontinued By Manufacturer

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC697RCM711 is a Redundancy Communication Module manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. This Redundancy Communications Module (RCM) provides a path for a synchronizing message from the active to the backup unit, which is used to synchronize the two CPUs in a Hot Standby or Enhanced Hot Standby CPU Redundancy system. It also provides the path for the transfer of shared I/O data between the two units. The physical connection between units in a redundancy system can have up to 25 feet (7.5 meters) of interconnecting cable.

The module occupies a single slot and has two connectors; the top connector is for attachment to the upstream ETBM or BRM, and the bottom connector is unused. The RCM can be installed in slots 2 through 9 of rack 0 (CPU rack). Five green LEDs provide status indication of the health of the RCM module and monitor the control status of the Hot Standby CPU Redundancy system. These LEDs are labeled BOARD OK, LOCAL READY, LOCAL ACTIVE, REMOTE READY, and REMOTE ACTIVE. Local refers to the system that the RCM is in; remote is the other system connected through the expansion bus and is automatically configured by the system to be in slot 1 of rack 7. Rack 7, however, is not available for physical I/O.

WOC has the largest stock of OEM Replacement Parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does the module support redundancy communication?

The module facilitates redundancy communication by providing a path for synchronizing messages between the active and backup units. This ensures that the backup unit is fully synchronized and ready to take over in the event of a failure of the active unit.

How does it handle I/O data transfer?

The module manages the transfer of I/O data between the active and backup units, ensuring that both units have consistent and up-to-date data. This helps maintain uninterrupted system operations even during unit switches.

What is the difference between Hot Standby and Hot Standby CPU Redundancy?

Both configurations involve one CPU operating as the active controller while the other remains on standby. Hot Standby ensures that the backup unit is ready to take over if needed, enhancing system reliability and availability.