World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200TCQCG1AGD - Analog I/O Expander Board is available in stock which ships the same day.

DS200TCQCG1AGD - Analog I/O Expander Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCQCG1AGD - Analog I/O Expander Board, contact us and we will get back to you within 24 hours.

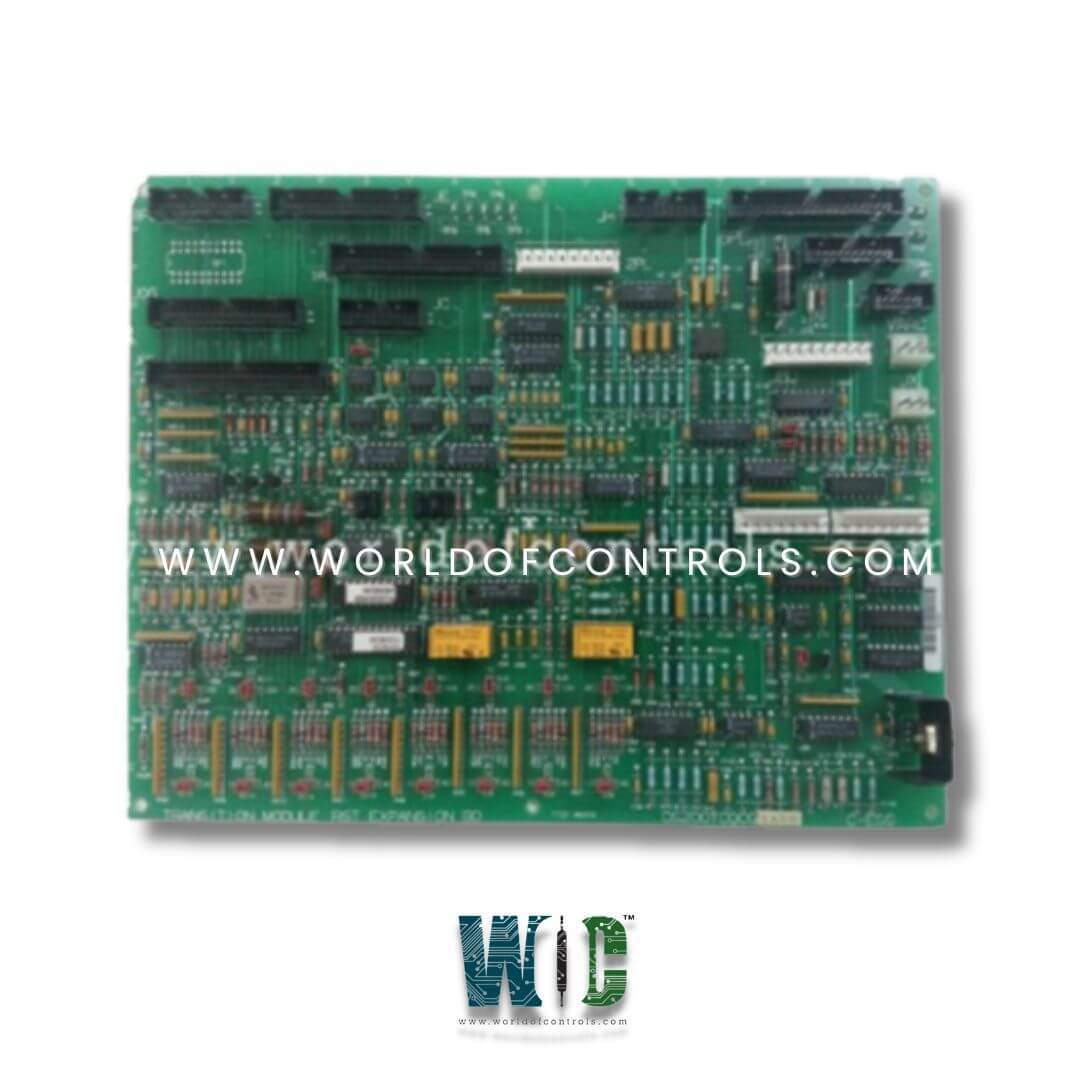

Part No.: DS200TCQCG1AGD

Manufacturer: General Electric

Product Type: Analog I/O Expander Board

Product Description: Analog I/O Expander Board

Country of Manufacture: United States (USA)

Series: Mark V

DS200TCQCG1AGD is an Analog I/O Expander Board developed by GE. It is a part of Mark V Series. It condition and scales signals from sources, including shaft speed, fuel flow, and power measurements, ensuring that data is efficiently transmitted to the relevant boards in the system. With its array of connectors and jumper settings, the TCQC board supports many configurations to meet the specific needs of turbine monitoring and control.

The most extensive assortment of GE Speedtronic Mark V control replacement components is available at World of Controls. Our experts are available to assist you with your Mark V requirements at any time. Please contact WOC if you require any additional information.

What is DS200TCQCG1AGD?

It is an Analog I/O Expander Board developed by GE.

Can the board handle multiple analog signals?

Yes, the board is capable of handling and conditioning multiple analog signals. It scales and processes signals from sensors, such as megawatt transducers and shaft speed sensors, and sends them to the appropriate boards for further analysis.

What is the function of the IONET termination on the TCQC board?

The IONET termination on the TCQC board is used to terminate communication signals between the TCEA board in the P1 core and the R1 core. This allows for proper signal transmission within the control system.