World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

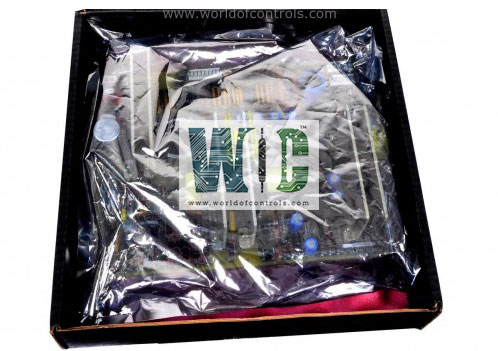

DS200TCCGA1ADA - Analog I/O Board is available in stock which ships the same day.

DS200TCCGA1ADA - Analog I/O Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCGA1ADA - Analog I/O Board, contact us and we will get back to you within 24 hours.

Part No.: DS200TCCGA1ADA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Analog I/O Board

Availability: In Stock

Series: Mark V

DS200TCCGA1ADA is an Analog I/O Board developed by GE. It is a part of the Mark V control system.The board supports the input of analog signals, such as 4-20 mA signals from sensors and transducers. These inputs are vital for monitoring parameters like temperature, pressure, and flow rates within industrial processes. It provides analog output channels capable of generating 4-20 mA signals. These outputs allow the control system to interface with actuators and devices that require analog control signals for operation and regulation.

The WOC team is always available to help you with your Mark V requirements. For more information, please contact WOC.

What is DS200TCCGA1ADA?

It is an Analog I/O Board developed by GE under the Mark V series.

What is the Mark V LM Control Panel by GE?

The Mark V LM Control Panel is a microprocessor-based turbine control system developed by GE. It is designed specifically for aero-derivative gas turbines, offering advanced capabilities in unit control, protection, and operational optimization across various industrial applications.

What are the core components of the Mark V LM Control Panel?

The Mark V LM Control Panel consists of cores, which are sheet metal housings housing stationary and movable printed circuit board holders (card carriers). Each core can accommodate up to five printed circuit boards and up to four I/O terminal boards, configured based on specific application requirements. This modular setup allows flexibility in adapting the control panel to different turbine configurations and operational needs.