SPECIFICATIONS

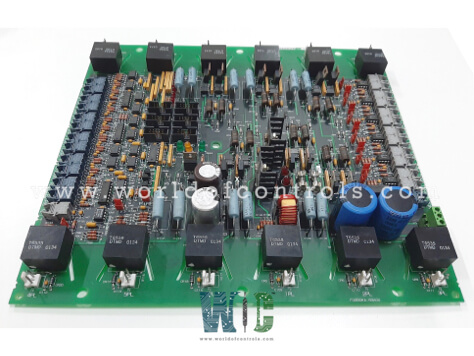

Part Number: DS200FCRRG1AJD

Manufacturer: General Electric

Series: Drive Control

Product Type: Firing Circuit Control Card

Size: 9.2x6.3 inches

Temperature 0 to 60oC (32 to 149 oF)

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

DS200FCRRG1AJD is a Firing Circuit Control Card developed by General Electric. It is a part of Drive Control series. Mark V embodies flexibility, allowing for seamless customization to meet diverse operational requirements. Whether regulating gas turbines or overseeing the intricacies of steam turbines, it provides unparalleled control, monitoring, and protection capabilities. The system prioritizes safety through robust protection features, safeguarding critical components and systems against potential risks and anomalies. This comprehensive approach to control and protection instills confidence in its operation, making it a cornerstone of modern power generation infrastructure.

Features

- Connectors: The board includes ten 2-pin connectors along the edges, as well as six cable connectors near the center. Additional connectors are positioned along both short board edges, facilitating various connections within the system.

- LED Indicators: Multiple LED indicators are integrated for diagnostic testing purposes, including one yellow, two green, and over a dozen red LEDs. The majority of the red LEDs are arranged in a line near the top left corner of the board.

- Installation and Handling: Due to its static-sensitive nature, caution should be exercised during installation and handling. Referencing the original GE documentation for detailed instructions is recommended to ensure proper installation and operation.

Control Modules

- In a Mark V Triple Modular Redundant (TMR) configuration, the controllers labeled R, S, and T function identically, executing critical control algorithms, protective functions, and sequencing tasks. These controllers are responsible for acquiring the necessary data to generate outputs to the turbine, ensuring seamless operation and safety.

- Protective outputs, vital for maintaining safe operation, are routed through the P module, which consists of triple redundant processors X, Y, and Z. These processors provide independent protection for critical functions such as overspeed, enhancing system reliability and safety.

- All three controllers acquire data from triple-redundant sensors, ensuring robust data acquisition even in the event of sensor failures. The number of sensors utilized depends on the specific turbine type, with critical sensors for continuous controls and protection being triple-redundant for added reliability.

- The C controller serves as the interface for non-critical and non-trip I/O, facilitating operator-maintenance interaction through two ARCNET ports. From this interface, operators can issue commands, monitor system parameters, and perform maintenance tasks such as changing control constants, editing application software, and adjusting I/O assignments and displays.

- Designed for ease of maintenance, the microprocessor-based controllers feature a modular design, with each module containing up to five boards, including a power supply. Multiple microprocessors within each controller handle processing tasks efficiently, with dedicated microprocessors assigned to specific I/O tasks and application software.

- Communication between controllers is facilitated through high-speed ARCNET links, ensuring seamless data exchange and system coordination. The controllers utilize ribbon cables and gas-tight connectors for reliable connections, further enhancing system integrity and performance.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

FREQUENTLY ASKED QUESTIONS

What is DS200FCRRG1AJD?

It is a Firing Circuit Control Card developed by General Electrics.

What safety features does the Mark V offer?

Safety is paramount in the Mark V system, with robust protection features designed to safeguard critical components and systems against potential risks and anomalies. These features provide operators with confidence in the system's reliability and operation.

Can the Mark V be customized to meet specific operational requirements?

Yes, the Mark V is highly flexible and can be customized to meet diverse operational needs. Its programmable nature allows for seamless customization, ensuring it can adapt to various turbine types and operational environments.