World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENQF1BDE01 - GE Software EPROM is available in stock which ships the same day.

DS200DENQF1BDE01 - GE Software EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENQF1BDE01 - GE Software EPROM, contact us and we will get back to you within 24 hours.

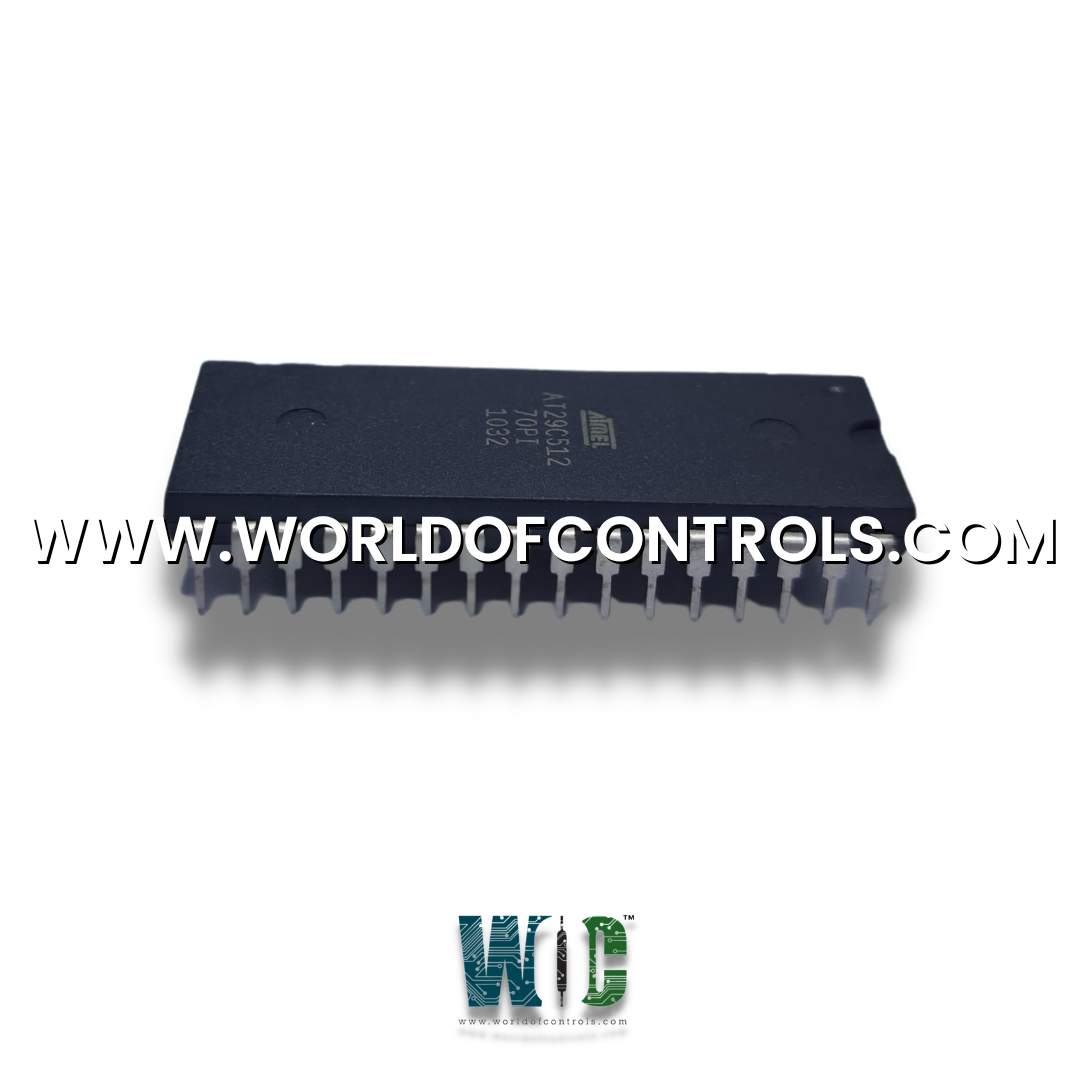

Part Number: DS200DENQF1BDE01

Manufacturer: General Electric

Series: Mark V

Product type: GE Software EPROM

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENQF1BDE01 is a GE software EPROM designed and developed by GE. It is a part of the Mark V control system. The Mark V system is primarily designed to control and monitor gas turbines, ensuring optimal performance and safety. It regulates various parameters such as fuel flow, speed, temperature, and pressure to maintain efficient turbine operation. It offers comprehensive protection features to safeguard the turbine against various operational issues, such as overspeed, over-temperature, and low oil pressure.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200DENQF1BDE01?

It is a GE Software EPROM designed and developed by GE

What role do diagnostics play in the synchronization process?

Diagnostics continuously monitors the actual breaker closure time and self-correct any deviations or discrepancies, ensuring a reliable and precise synchronization process.

How does this system enhance reliability while eliminating traditional components?

The system eliminates the need for the traditional GXS synchronizing check relay and, instead, uses redundant sets of primary and backup phase-slip windows, streamlining synchronization while enhancing overall system reliability.

Can operators engage in manual synchronization, and how?

Yes, operators can manually synchronize the system through the Mark V operator interface, replacing the traditional synchroscope. This provides operators with more control and adaptability.

Is there an option for operators to review synchronization data before issuing a breaker close command?

Yes, there is a monitor mode that automatically aligns speed and voltage but waits for the operator to review data on the CRT interface before initiating the breaker close command.

What is the ultimate goal of the synchronization process?

The synchronization process aims to ensure that electrical systems come into perfect alignment, guaranteeing a seamless transfer of power and maintaining the stability and reliability of the overall electrical infrastructure.