SPECIFICATIONS

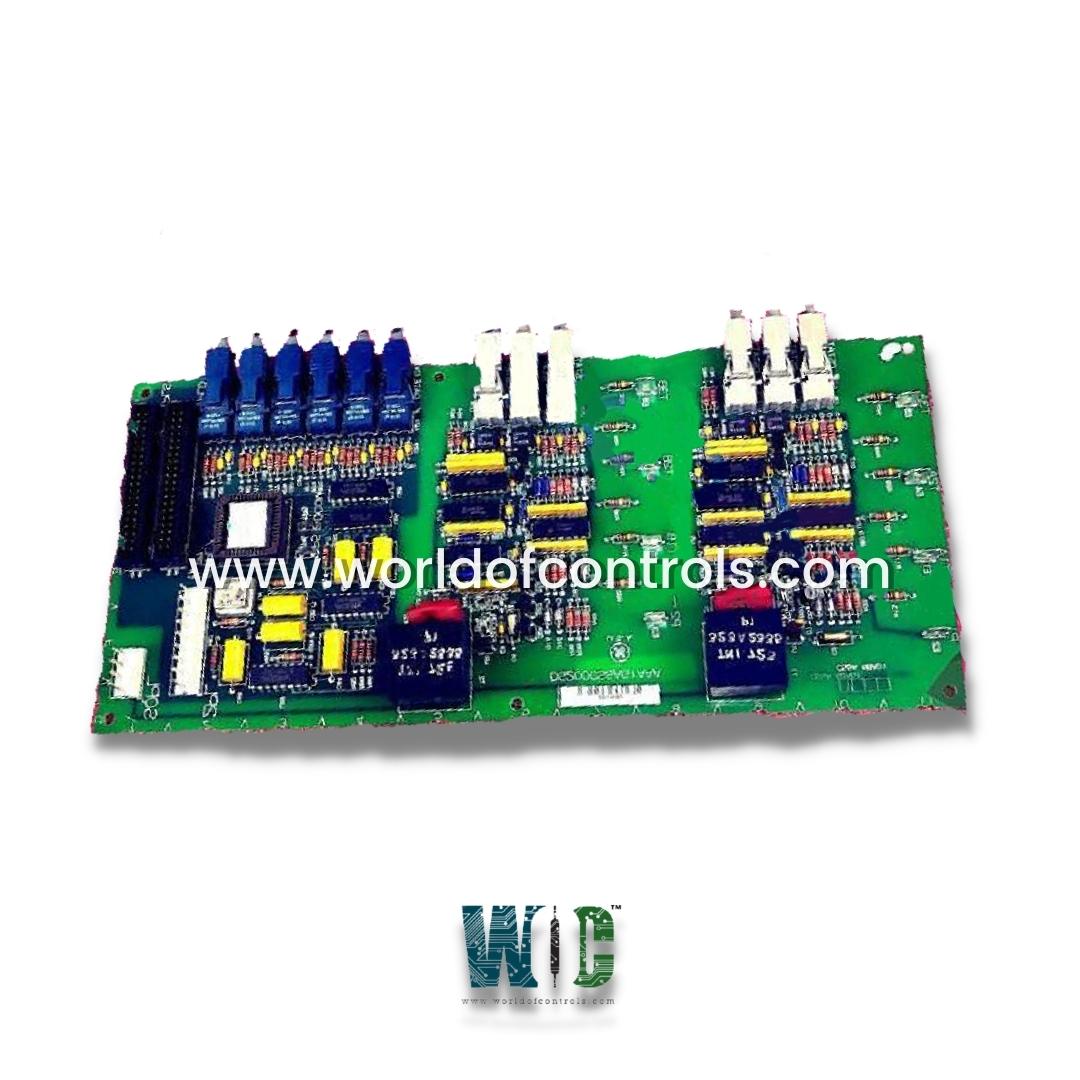

Part No.: DS200CSSAG1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature: 0 to 60 oC

Product Type: Cell State Sensor Board

Availability: In Stock

Series: EX2000

Functional Description

DS200CSSAG1A is a Cell State Sensor Board developed by GE. It is a part of the EX2000 excitation system. It is a component used in managing and regulating power generation systems. This board is designed with precision to monitor and regulate several critical aspects of the excitation system’s operation, ensuring that the system performs optimally and remains reliable over time.

Key Features and Specifications

- Compact Size: Despite its advanced functionality, the board has a compact design, measuring 4 inches in height and 11 inches in width. This allows it to fit into tight spaces within power control cabinets and systems, where space is often limited. Its efficient design ensures that it can integrate into the broader EX2000 excitation system seamlessly.

- Connectors and Integration: Equipped with several connectors that ensure easy integration with other system components and peripherals. Specifically, it features:

- Two 40-pin connectors, which are used for data transfer and communication with other parts of the excitation system.

- One 4-pin connector, which typically handles power supply or other auxiliary connections.

- One 9-pin connector, which can be used for additional communication or control functions.

- These connectors allow the board to be integrated with other system modules, sensors, and communication devices within the EX2000 excitation system, enabling seamless operation across the entire system.

- Voltage Limitation and Suppression: The board incorporates several hardware components designed to handle voltage limitations and suppression, preventing spikes or fluctuations that could damage other system components. These features ensure that the board operates within safe voltage ranges and helps protect sensitive equipment connected to the excitation system.

- Standardized Mark V Series Components: It is built using Mark V Series-standardized hardware components. These components are recognized for their reliability and durability in industrial power generation applications. The use of standardized parts means that the board can be easily maintained, repaired, or replaced with other Mark V Series components, enhancing the system’s flexibility and long-term supportability.

- Internal Assembly: The internal assembly makes use of various high-quality components designed to ensure smooth operation, including capacitors, resistors, and other electronics that facilitate signal processing, voltage regulation, and system monitoring. The use of these reliable components is key to ensuring the board's durability and performance in demanding environments.

- PCB Coating Style: features the normal PCB coating style, which protects the internal circuitry from environmental factors such as dust, moisture, and other contaminants. This coating helps extend the lifespan of the board and ensures stable performance, even in harsh industrial environments where the board may be exposed to varying conditions.

System Software

- The software design of the exciter application represents a sophisticated approach to control system emulation, leveraging an open architecture system and a library of existing software blocks. These blocks, each tailored to perform specific functions, form the building blocks of the software, enabling the implementation of complex control systems with ease and flexibility.

- At its core, the software utilizes an open architecture system, which fosters modularity and adaptability by allowing for the incorporation of various software blocks. These blocks encompass a diverse range of functionalities, including logical AND gates, proportional integral (P.I.) regulators, function generators, and signal-level detectors. Each block is designed to execute a specific task, thereby enabling the emulation of traditional analog controls within a digital framework.

- The integration of these software blocks follows a pattern wherein they are interconnected to implement complex control systems. For instance, to incorporate a control function such as the under-excitation limit (UEL), software jumpers are configured in the Electrically Erasable Programmable Read-Only Memory (EEPROM). This process enables the relevant blockware to be enabled, with inputs directed to specific Random Access Memory (RAM) locations where the inputs are stored. In the case of the UEL, inputs such as megawatts, kilovolts, and megavars are utilized. The output of the UEL block is then directed to an input of the alternating current (AC) regulator summing junction, thereby completing the integration of the control function into the overall system.

- The execution of these software blocks is orchestrated by the block interpreter, which operates according to a predefined order and execution rate defined in the toolbox. This sequential execution ensures that the control system operates efficiently and reliably, with each block fulfilling its designated role in a timely manner.

The WOC team is always available to help you with your EX2000 requirements. For more information, please contact WOC.

Frequently Asked Questions

What is DS200CSSAG1A?

It is a Cell State Sensor Board developed by GE under the EX2000 series.

How is a control function like the under-excitation limit (UEL) integrated into the software design?

The UEL, along with other control functions, is incorporated into the software by configuring software jumpers in the EEPROM. Inputs required for the UEL, such as megawatts, kilovolts, and megavars, are directed to specific RAM locations, and the output of the UEL block is connected to the AC regulator summing junction.

What role does the block interpreter play in the software design?

The block interpreter sequentially executes the software blocks according to a predefined order and execution rate defined in the toolbox. It ensures that each block operates efficiently and reliably, contributing to the overall functionality of the control system.

How does the software design enhance the flexibility and efficiency of the excitation system?

The software design's modularity and adaptability allow for the seamless integration of complex control functions. This flexibility enables the excitation system to meet diverse industrial requirements while maintaining efficiency and reliability.