SPECIFICATIONS

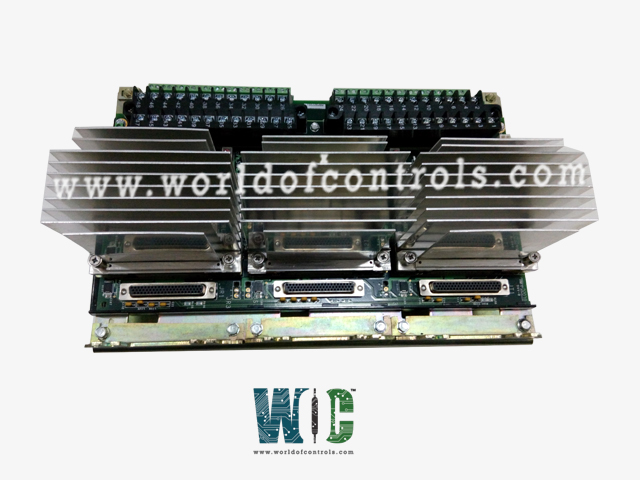

Part No.: IS230TSVCH2A

Manufacturer: General Electric

Series: Mark VIe

Function: Servo Control TMR Module

Power supply voltage: 24 V dc

Power supply current: 5 A dc

Repair: 3-5 Days

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

IS230TSVCH2A is a Servo Input/Output (TSVC) Terminal Board developed by GE. It is a part of mark VIe control system. The Servo Input/Output (TSVC) terminal boards primary function involves establishing a vital connection between two electro-hydraulic servo valves, which in turn play a critical role in the manipulation of steam/fuel valves within the system. These servo valves are responsible for precisely modulating the flow of fluids, thereby governing the operation of the steam/fuel valves. To ascertain accurate valve positions, the TSVC employs linear variable differential transformers (LVDT). These ingenious devices are capable of translating mechanical displacements into corresponding electrical signals, enabling the system to gauge the precise positions of the valves. This positional feedback is essential for maintaining the system's stability and ensuring that the valves respond accurately to control inputs.

Features

- Seamlessly integrate with the PSVO I/O pack and the WSVO servo driver. However, compatibility is not universal, it is not designed to interface with the VSVO processor. This specificity underscores the critical role the module plays in the unique context of the PSVO I/O pack and WSVO servo driver combination.

- In terms of control capabilities, the terminal board provides support for three distinct modes: simplex, dual, and TMR (Triple Modular Redundancy) control. These modes offer varying levels of redundancy and failover mechanisms, ensuring the reliability and robustness of the control system even in the face of component failures.

- Three 28 V DC supplies are channeled into the system through plug J28. This provision of power is pivotal for driving the various components and ensuring the smooth operation of the entire setup.

- For external safety mechanisms, the terminal board features plugs JD1 and JD2, which are designated for an external trip initiated from the protection module. This safety measure adds an additional layer of security, enabling the protection module to intervene and trigger a system shutdown or other appropriate actions in case of any detected anomalies or hazardous conditions.

Installation

- In control system architecture, a pivotal nexus exists where sensors and servo valves converge with precision. This amalgamation is facilitated through a direct wiring scheme, establishing a direct and deterministic link between these critical components. The linchpin of this connection lies in the form of two dedicated Input/Output (I/O) terminal blocks, both meticulously engineered to accommodate the intricate interplay of control signals.

- These terminal blocks are firmly secured using a dual-screw fastening mechanism, ensuring structural stability even in dynamic operational environments. A noteworthy characteristic of these blocks is the comprehensive provision of 24 terminals, each meticulously designed to admit wiring of up to #12 AWG gauge. This foresight in accommodating varying wire thicknesses provides versatility and adaptability, catering to the diverse wiring specifications that may arise in practical applications.

- To uphold the system's electromagnetic compatibility and mitigate potential interference, a shield terminal strip is strategically positioned in close proximity to each I/O terminal block. This shield terminal strip, intrinsically tied to the system's chassis ground, serves as a conduit for dissipating electromagnetic interference, thereby safeguarding the integrity of control signals and preserving the precision of the system's operation.

- The system architecture anticipates contingencies and external safety mechanisms through the integration of external trip wiring interfaces. These interfaces, denoted as JD1 and JD2, are purpose-built to accommodate external trip signals originating from safeguarding modules or auxiliary systems. By virtue of these interfaces, the control system can promptly respond to critical conditions, initiating protective measures or shutdown protocols as warranted by the situation.

- The sophistication of the servo valve outputs is elevated through the implementation of a Triple Modular Redundancy (TMR) configuration. This advanced arrangement empowers each servo output with the capability to interface with three distinct coils. Such redundancy fortifies the system against single-point failures, ensuring uninterrupted operation even if a single coil encounters an anomaly or malfunction.

- Tailoring the system's performance to varying operational requirements is achieved through the judicious manipulation of coil current magnitudes. This customization is accomplished by means of strategically positioned jumpers: JP1, JP3, and JP5 for Servo 1, and JP2, JP4, and JP6 for Servo 2. The state of these jumpers meticulously dictates the amplitude of the current coursing through the coils, effectively fine-tuning the servo output performance.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS230TSVCH2A?

It is a Servo Control TMR Module developed by GE

What is the role of LVDTs in the TSVC servo terminal board?

LVDTs are utilized for precise measurement of valve positions. The TSVC terminal board is capable of providing excitation to and receiving inputs from up to eight LVDT valve position sensors. The setup allows for flexibility, accommodating a choice of one, two, three, or four LVDTs for each servo control loop.

How are pulse rate inputs used in conjunction with the terminal board?

The servo terminal board features two pulse rate inputs designed for gas turbine fuel flow measurement. These inputs enable accurate monitoring and measurement of fuel flow rates in the gas turbine system.

How are the output status and performance of the servo outputs monitored?

The terminal board incorporates diagnostics that actively monitor the output status of each servo. This monitoring includes parameters such as servo voltage, current, and the status of the suicide relay. This comprehensive diagnostic feature enhances the system's ability to detect and respond to potential issues promptly.